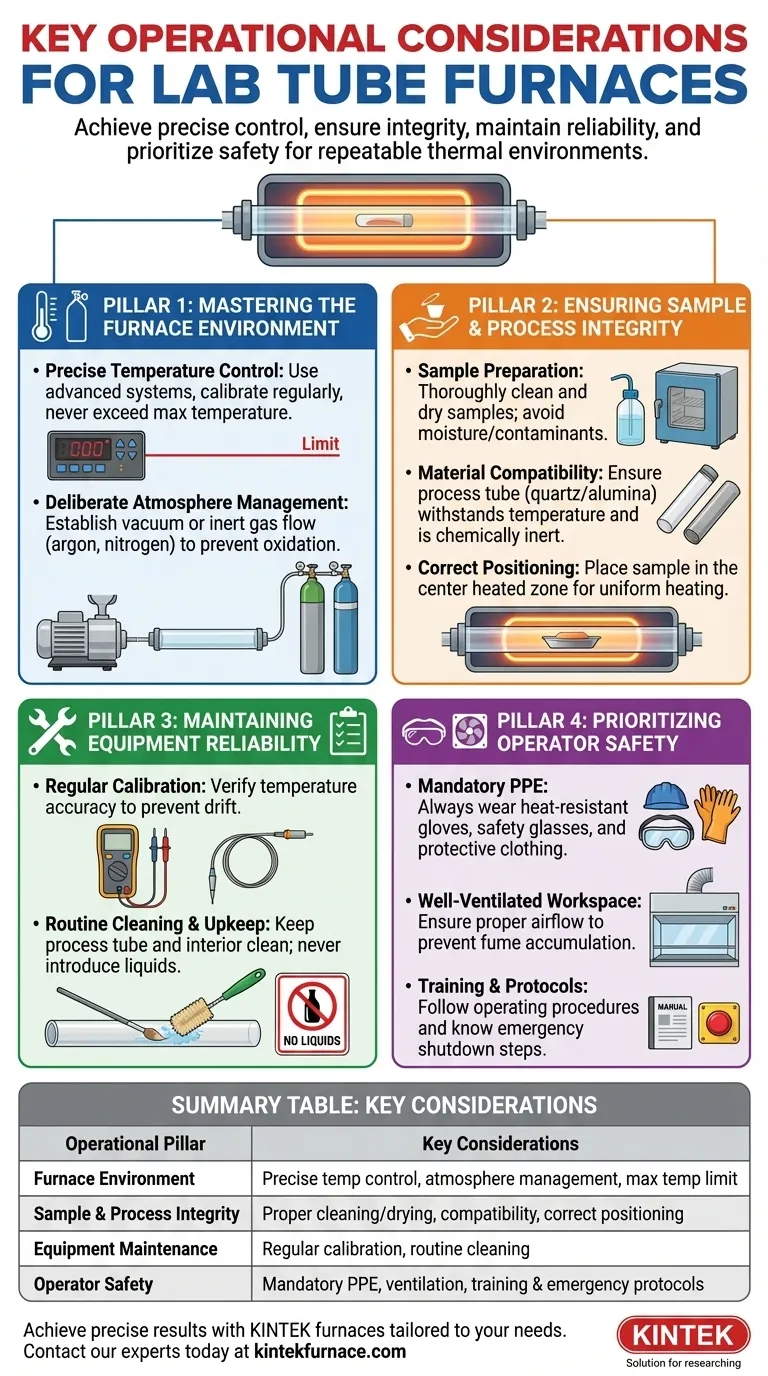

Operating a lab tube furnace requires a disciplined approach focused on four critical areas: precise control of the internal environment, meticulous sample preparation, diligent equipment maintenance, and unwavering adherence to safety protocols. Success depends on managing the interplay between temperature and atmosphere while ensuring the sample is compatible with the furnace materials and positioned correctly for uniform heating.

The core principle of using a tube furnace is not simply heating a sample, but creating a highly controlled and repeatable thermal environment. Every operational step, from sample preparation to shutdown, is about protecting the integrity of your experiment, the equipment, and yourself.

Pillar 1: Mastering the Furnace Environment

The primary function of a tube furnace is to establish a precise and stable environment. This is a combination of two independent but related variables: temperature and atmosphere.

Precise Temperature Control

A modern tube furnace relies on an advanced control system with sensors, like thermocouples, to achieve and maintain a set temperature.

However, the controller's reading is only as good as its calibration. Accurate, repeatable results depend on knowing the furnace is performing to specification.

Crucially, you must never exceed the furnace's rated maximum temperature. Doing so can cause permanent damage to the heating elements and the furnace lining, creating both a safety hazard and an expensive failure.

Deliberate Atmosphere Management

Many processes require an environment other than ambient air. This is achieved by creating either a vacuum or a flow of a specific inert gas, such as argon or nitrogen.

Atmosphere control is essential for preventing unwanted oxidation or reactions. It requires managing gas flow rates from cylinders or operating vacuum pumps to achieve the desired pressure and gas composition within the tube.

Pillar 2: Ensuring Sample and Process Integrity

The furnace provides the environment, but the sample is the subject. How you prepare and handle it directly impacts the validity of your results.

The Importance of Sample Preparation

Samples must be properly cleaned and dried before being placed in the furnace. Any residual moisture or contaminants can vaporize at high temperatures, altering the furnace atmosphere and potentially reacting with your sample.

Equally important is material compatibility. The process tube, typically made of quartz or alumina, must be able to withstand the target temperature and be chemically inert to your sample material to avoid contamination.

Correct Sample Positioning

For consistent results, the sample should be placed in the center of the furnace's heated zone. This is where the temperature is most uniform.

Placing a sample too close to the ends of the tube can result in incomplete heating or processing due to thermal gradients.

Pillar 3: Maintaining Equipment Reliability

A tube furnace is a precision instrument that demands regular care. Neglecting maintenance compromises its performance, longevity, and safety.

The Role of Regular Calibration

Temperature calibration is vital for ensuring the accuracy of your experiments. Over time, thermocouples can drift, leading to a discrepancy between the setpoint temperature and the actual temperature.

Regular calibration verifies that the furnace is operating accurately, which is fundamental for process control and generating reproducible data.

Routine Cleaning and Upkeep

The process tube and the interior of the furnace must be kept clean at all times. Contamination from previous experiments can compromise future runs.

Never pour any liquids or dissolved metals directly into the furnace chamber, as this can cause severe damage to the heating elements and insulation.

Pillar 4: Prioritizing Operator Safety

High temperatures and controlled atmospheres present inherent risks. A systematic approach to safety is non-negotiable.

Personal Protective Equipment (PPE) is Mandatory

Always wear appropriate PPE when operating a furnace. This includes heat-resistant gloves, safety glasses, and protective lab clothing.

These simple measures are your first line of defense against thermal burns and other potential injuries.

Managing the Workspace Environment

The area around the furnace must be well-ventilated. This is especially critical when working with process gases to prevent the accumulation of potentially harmful or asphyxiating fumes.

Keep the area clear of flammable materials and ensure there is unobstructed access to the furnace controls and shut-off switches.

The Necessity of Training and Emergency Protocols

No one should operate a tube furnace without receiving proper training on its specific operating procedures and safety features.

All users must be familiar with emergency shutdown procedures, including how to cut power and shut off gas supplies in the event of a malfunction.

Making the Right Choice for Your Goal

Your operational focus will shift slightly depending on your experimental objective.

- If your primary focus is high-purity material synthesis: Prioritize meticulous tube cleaning and effective atmosphere control to prevent any sample contamination.

- If your primary focus is material property testing (e.g., annealing, sintering): Emphasize precise temperature calibration and correct sample positioning to ensure process accuracy and repeatability.

- If your primary focus is general lab use or student training: Place the highest emphasis on understanding and enforcing all safety protocols, from PPE to emergency shutdown procedures.

Ultimately, disciplined operation transforms the tube furnace from a simple heater into a precision instrument for scientific discovery.

Summary Table:

| Operational Pillar | Key Considerations |

|---|---|

| Furnace Environment | Precise temperature control, atmosphere management (vacuum/inert gas), never exceed max temperature |

| Sample & Process Integrity | Proper sample cleaning/drying, material compatibility, correct positioning in the heated zone |

| Equipment Maintenance | Regular temperature calibration, routine cleaning of the process tube and furnace interior |

| Operator Safety | Mandatory PPE (gloves, glasses), well-ventilated workspace, proper training and emergency protocols |

Achieve precise and repeatable results with a furnace built for your specific needs.

Operating a tube furnace successfully requires not just discipline, but also the right equipment. The principles outlined above—precise environment control, sample integrity, reliability, and safety—are the foundation of KINTEK's furnace designs.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, and other lab high-temperature furnaces, all customizable for your unique process requirements. Whether your focus is high-purity synthesis, material testing, or training, we provide the robust and accurate tools you need for discovery.

Ready to enhance your lab's capabilities? Contact our experts today to discuss how a KINTEK furnace can be tailored to your application.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision