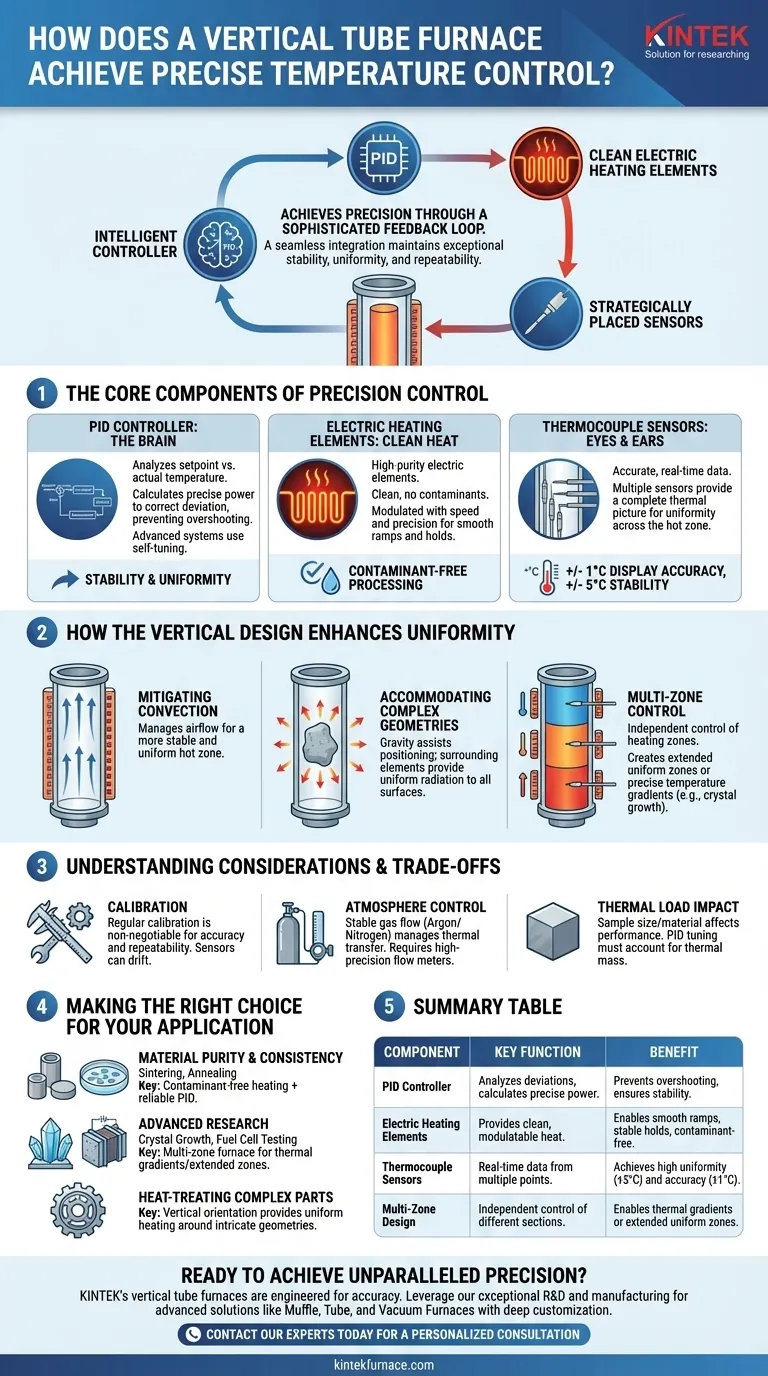

At its core, a vertical tube furnace achieves precise temperature control through a sophisticated feedback loop. This system combines an intelligent controller that anticipates temperature changes, clean electric heating elements that can be finely adjusted, and strategically placed sensors that provide real-time data on the furnace's internal environment.

The furnace’s precision does not come from a single component, but from the seamless integration of a PID control system, high-purity electric heating, and accurate temperature sensing. This trio works in constant communication to maintain exceptional stability, uniformity, and repeatability for sensitive processes.

The Core Components of Precision Control

To understand how a vertical tube furnace operates with such accuracy, we must look at the key technologies that form its control system. These components work together to execute complex heating profiles down to a single degree.

The PID Controller: The Brain of the Operation

The primary driver of temperature precision is the Proportional-Integral-Derivative (PID) controller. This is far more advanced than a simple thermostat that just turns the heat on or off.

A PID system constantly analyzes the difference between the setpoint temperature and the actual measured temperature. It then calculates the exact amount of power to send to the heating elements to correct any deviation, preventing overshooting or undershooting the target.

Advanced systems may also incorporate self-tuning technologies or fuzzy logic to automatically optimize the PID parameters for different thermal loads or processes, further enhancing accuracy.

Electric Heating Elements: The Source of Clean Heat

Modern laboratory furnaces use high-temperature electric heating elements. Unlike combustion-based methods, electric heating is perfectly clean, producing no byproducts that could contaminate sensitive samples.

Crucially, the power supplied to these elements can be modulated with incredible speed and precision by the PID controller. This allows for smooth, controlled temperature ramps and stable holding periods, which are vital for consistent results.

Thermocouple Sensors: The Eyes and Ears

The entire control system relies on accurate, real-time data. This is provided by thermocouple sensors placed throughout the furnace chamber.

The vertical configuration often makes it easier to position multiple sensors around the sample or "charge." This comprehensive monitoring provides the PID controller with a complete picture of the thermal environment, enabling it to ensure temperature uniformity across the entire hot zone. This is how furnaces can achieve a display accuracy of ±1℃ and a temperature field stability of ±5℃.

How the Vertical Design Enhances Uniformity

While the control system is the brain, the furnace's physical structure plays a critical role in its performance. The vertical orientation is a deliberate design choice that directly contributes to thermal stability.

Mitigating Convection Effects

In any heated chamber, natural convection currents can create temperature variations. A vertical tube design helps manage this airflow, contributing to a more stable and uniform hot zone compared to some horizontal orientations.

Accommodating Complex Geometries

The vertical loading configuration is ideal for parts with complex shapes or an "increased structure." Gravity assists in positioning the item, and the surrounding heating elements can provide more uniform radiation to all surfaces simultaneously.

Multi-Zone Control for Gradient Heating

Many advanced vertical furnaces feature multi-temperature zone designs. Each zone is equipped with its own set of heating elements and a dedicated thermocouple, controlled independently.

This allows for either creating an exceptionally long and uniform hot zone or programming a precise temperature gradient along the length of the tube—a capability essential for specialized applications like crystal growth and catalyst testing.

Understanding the Trade-offs and Considerations

Achieving and maintaining precision requires more than just advanced hardware. To ensure reliable results, you must understand the factors that influence the system's performance.

The Importance of Calibration

A control system is only as accurate as its sensors. Thermocouples can drift over time, especially at high temperatures. Regular calibration is non-negotiable to maintain the furnace's specified accuracy and ensure process repeatability.

Atmosphere Control is Interlinked

Precise temperature control is often paired with precise atmosphere control. The introduction of gases like argon or nitrogen to prevent oxidation can alter the thermal transfer characteristics inside the furnace. A stable gas flow, managed by high-precision flow meters, is crucial for maintaining a stable thermal environment.

The Impact of the Thermal Load

The size, shape, and material of the sample being heated (the "thermal load") directly impacts furnace performance. A larger or denser load requires more energy to heat and can create temperature gradients. The PID controller must be tuned properly to account for this thermal mass to avoid slow response times or temperature inaccuracies.

Making the Right Choice for Your Application

Ultimately, the level of precision you require is dictated by your specific goal. Understanding the furnace's capabilities allows you to match the right tool to the task.

- If your primary focus is material purity and consistency (e.g., sintering, annealing): The combination of contaminant-free electric heating and a reliable PID controller is your key to achieving repeatable, high-quality results.

- If your primary focus is advanced research (e.g., crystal growth, fuel cell testing): A multi-zone vertical furnace provides the necessary control to establish the precise thermal gradients or extended uniform zones your process demands.

- If your primary focus is heat-treating complex parts: The vertical furnace's ability to provide uniform heating around intricate geometries ensures that all surfaces receive the correct thermal treatment.

By understanding these integrated systems, you can confidently leverage the furnace's precision to achieve your desired outcome.

Summary Table:

| Component | Key Function | Benefit |

|---|---|---|

| PID Controller | Analyzes temperature deviations and calculates precise power adjustments. | Prevents overshooting/undershooting, ensures stability. |

| Electric Heating Elements | Provides clean, modulatable heat based on controller signals. | Enables smooth ramps, stable holds, and contaminant-free processing. |

| Thermocouple Sensors | Delivers real-time temperature data from multiple points in the chamber. | Achieves high temperature uniformity (±5°C) and display accuracy (±1°C). |

| Multi-Zone Design | Allows independent control of different sections of the furnace tube. | Enables precise thermal gradients or extended uniform hot zones for advanced R&D. |

Ready to achieve unparalleled precision in your thermal processes?

KINTEK's vertical tube furnaces are engineered for researchers and engineers who cannot compromise on accuracy. Leveraging our exceptional in-house R&D and manufacturing capabilities, we provide advanced solutions like Muffle, Tube, and Vacuum Furnaces, with deep customization to meet your unique experimental requirements—whether for sintering, crystal growth, or heat-treating complex parts.

Let's discuss how we can build a furnace solution that delivers the exact control your work demands. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety