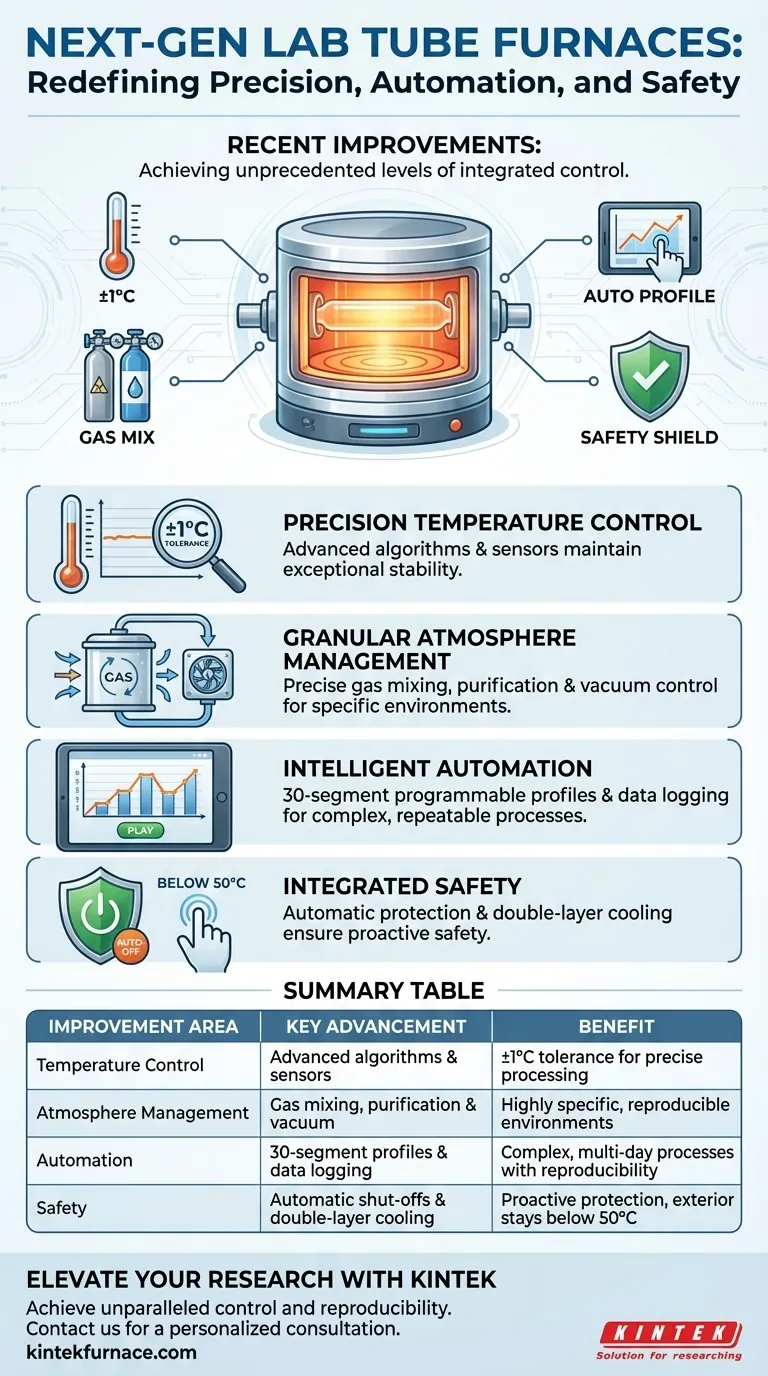

In short, recent improvements in lab tube furnaces have centered on achieving unprecedented levels of precision, automation, and integrated safety. Key advancements include superior temperature control algorithms capable of maintaining tolerances of ±1°C, alongside sophisticated atmosphere management systems that allow for precise gas mixing, purification, and vacuum control.

The core takeaway is that modern tube furnaces are no longer just heating elements; they are highly integrated experimental systems. These upgrades in digital control and safety transform them from simple tools into reliable, automated platforms that enable more complex, reproducible, and safer research.

The Evolution of Precision Environmental Control

The fundamental goal of a tube furnace is to create a specific, stable thermal environment. Recent advancements have radically improved our ability to define and maintain that environment with exceptional accuracy.

Achieving Tighter Temperature Uniformity

Modern furnaces now leverage advanced temperature sensors and intelligent control algorithms. This combination allows them to actively predict and counteract thermal fluctuations.

The result is a much higher degree of accuracy and stability, with many systems now achieving temperature tolerances of ±1°C or better across the heating zone. This level of precision is critical for sensitive processes like crystal growth or calibrating material phase transitions.

Granular Atmosphere Management

Beyond temperature, controlling the chemical environment is paramount. Newer models feature advanced atmosphere management systems that move far beyond a simple inert gas purge.

These systems incorporate gas mixing and purification technologies, enabling researchers to create highly specific and reproducible reaction atmospheres. This is essential for preventing unwanted oxidation or studying the effects of specific reactive gases on a sample.

The Rise of Intelligent Automation

The most significant shift has been from manual operation to intelligent, programmable automation. This enhances not only convenience but also the scientific validity of the experiments being run.

Programmable, Multi-Step Processes

Many furnaces now include controllers that support 30-segment programmable profiles. This allows users to design and save complex heating, dwelling, and cooling cycles.

The ability to preset and recall up to 15 or more unique sintering curves means that intricate, multi-day processes can be automated. This ensures perfect run-to-run reproducibility and frees up valuable researcher time.

Intuitive Interfaces and Data Logging

Operation is simplified through modern 7-inch color touch screens and intuitive user interfaces. These systems provide real-time monitoring of all critical parameters.

Crucially, many now feature integrated data logging and reporting capabilities. This provides a complete record of the experimental conditions, which is invaluable for analysis, troubleshooting, and publication.

Redefining Safety as an Integrated Feature

Safety is no longer an afterthought or external add-on; it is now deeply integrated into the furnace's core design and control logic.

Proactive System Protection

Modern furnaces are equipped with a suite of automatic protection functions. These systems constantly monitor for over-temperature, over-pressure, and even tube breakage.

If an abnormal condition is detected, the furnace can trigger an emergency shut-off, securing the system and protecting both the equipment and the operator without requiring manual intervention.

Operator-Focused Safety Design

Hardware design has also improved significantly. A common feature is the double-layer steel shell with fan cooling.

This design actively dissipates heat, ensuring the external surface of the furnace remains below 50°C. This dramatically reduces the risk of accidental burns and makes the immediate lab environment safer.

How to Apply This to Your Research

Choosing the right furnace means matching its specific capabilities to your primary experimental goals.

- If your primary focus is high-purity material synthesis: Prioritize models with advanced atmosphere control, including gas mixing, purification, and high-vacuum capabilities.

- If your primary focus is complex, repeatable thermal processing: Look for furnaces with multi-segment programmable controllers and the ability to save numerous custom profiles.

- If your primary focus is a multi-user lab environment: Emphasize integrated safety features like automatic shut-offs and cool-to-the-touch exteriors, coupled with an intuitive touchscreen interface.

These advancements empower you to conduct research with greater control, confidence, and precision than ever before.

Summary Table:

| Improvement Area | Key Advancement | Benefit |

|---|---|---|

| Temperature Control | Advanced algorithms & sensors | Maintains tolerances of ±1°C for precise thermal processing |

| Atmosphere Management | Gas mixing, purification & vacuum control | Creates highly specific, reproducible reaction environments |

| Automation | 30-segment programmable profiles & data logging | Enables complex, multi-day processes with perfect reproducibility |

| Safety | Automatic shut-offs & double-layer cooling | Proactively protects equipment and operators, exterior stays below 50°C |

Ready to elevate your research with a next-generation tube furnace?

KINTEK's advanced lab furnaces integrate these precise improvements directly into your workflow. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique experimental needs.

Achieve unparalleled control and reproducibility in your lab. Let our team help you select the perfect system to empower your research.

Contact KINTEL today for a personalized consultation!

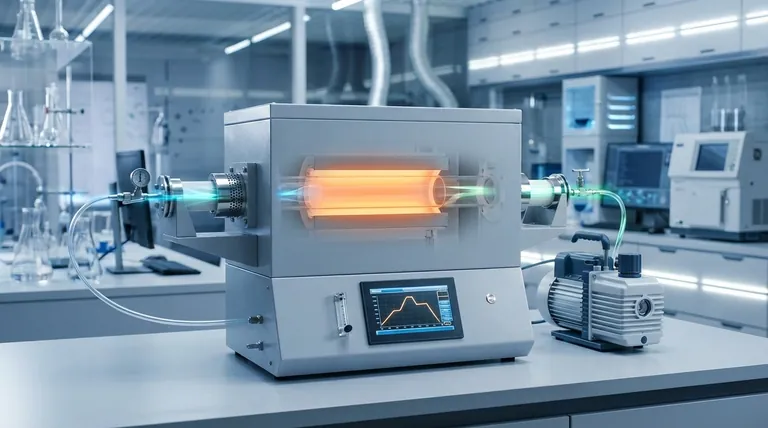

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab