The required medium for a water circulating vacuum pump is, quite simply, water or another liquid that shares very similar chemical and physical properties. This design choice is fundamental to the pump's operation, as the liquid is not just a coolant but the active component responsible for creating the vacuum itself.

The performance and lifespan of a water circulating vacuum pump are directly tied to the quality of the water used. While the system is designed for water, understanding why is key to avoiding poor performance and premature equipment failure.

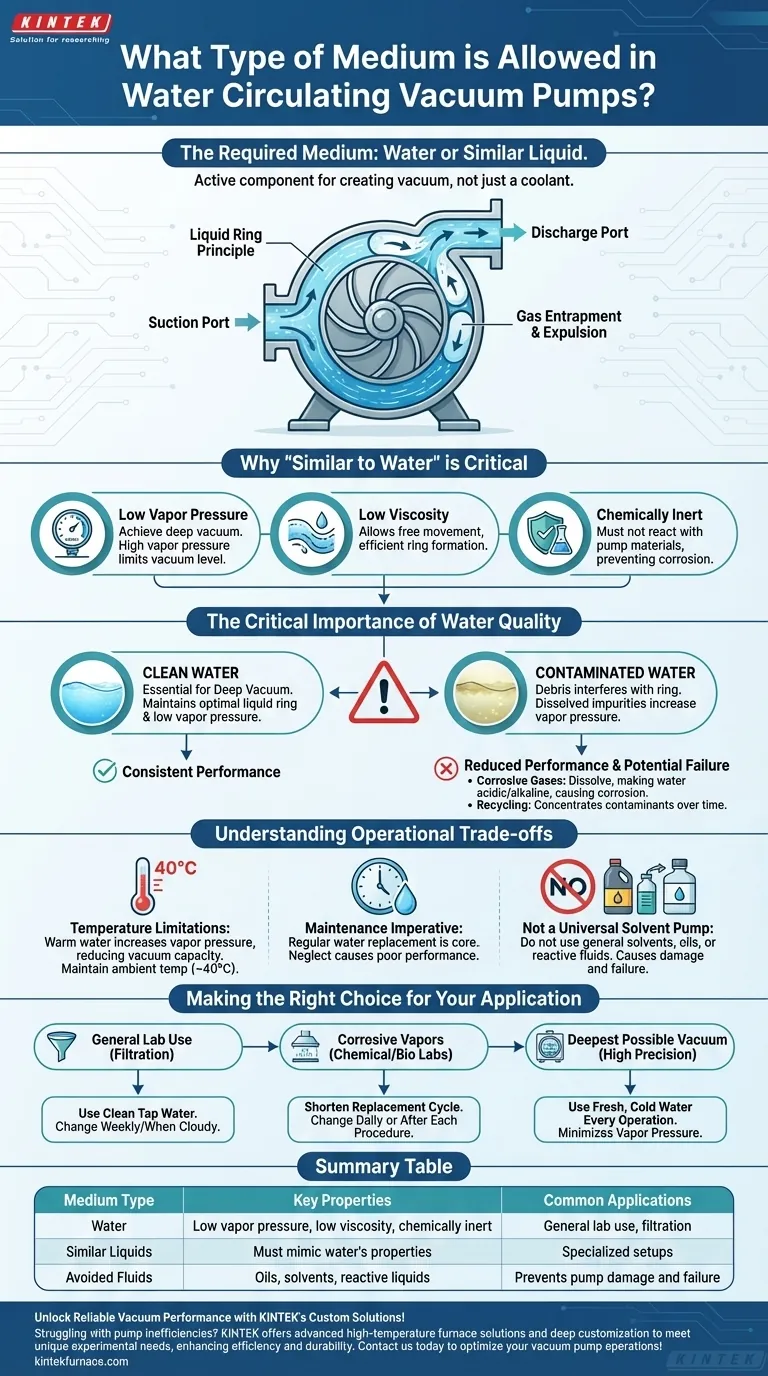

How the Liquid Medium Creates a Vacuum

These pumps, often a type of liquid-ring pump, do not use oil or mechanical seals in the vacuum chamber. Instead, they rely entirely on the properties of the circulating liquid to generate low pressure and remove gases.

The Principle of the Liquid Ring

A rotating impeller inside the pump housing throws the liquid (water) outwards by centrifugal force. This forms a moving ring of liquid that seals against the pump casing. Because the impeller is mounted off-center, the space between the impeller hub and the liquid ring changes, creating pockets that expand and contract.

Gas Entrapment and Expulsion

As the pockets expand, they create a low-pressure zone that draws gas in from the suction port. As the impeller continues to rotate, these gas-filled pockets shrink, compressing the gas before it is expelled along with some of the liquid through the discharge port.

Why "Similar to Water" is Critical

For a liquid to be a suitable substitute for water, it must have a similar low vapor pressure (to achieve a deep vacuum), low viscosity (to move freely), and be chemically inert to the pump materials. Using an inappropriate liquid can drastically reduce performance or damage the pump.

The Critical Importance of Water Quality

The water in the tank is a working component, not just a passive fluid. Its condition has a direct and immediate impact on the vacuum system.

Maintaining a Deep Vacuum

Clean water is essential for achieving the pump's specified vacuum level. Debris can interfere with the formation of the liquid ring, while dissolved impurities can increase the water's vapor pressure, limiting how low the system pressure can go.

Handling Corrosive Gases

When pumping corrosive gases (common in chemical and biological labs), these gases dissolve into the circulating water. This makes the water itself acidic or alkaline, which will corrode the internal components of the pump over time.

The Double-Edged Sword of Recycling

The ability to recycle the water in the tank is a major benefit, especially in labs with limited water supply. However, this closed-loop operation also means that any contaminants, including absorbed gases, become more concentrated over time, accelerating wear.

Understanding the Operational Trade-offs

While robust and reliable, these pumps have specific operational limits that are important to respect for both safety and performance.

Temperature Limitations

The vacuum level a pump can achieve is limited by the vapor pressure of the sealing liquid. Using warm water significantly increases its vapor pressure, creating more water vapor in the system and preventing it from reaching a deep vacuum. This is why an ambient temperature limit, typically around 40°C, is specified.

The Maintenance Imperative

Regularly replacing the water is not optional maintenance; it is a core operational requirement. Neglecting this simple task is the most common cause of poor performance and eventual pump failure. Clean, cool water is the lifeblood of the system.

Not a Universal Solvent Pump

These pumps are explicitly designed for water. While a liquid with nearly identical properties might work, you cannot use general solvents, oils, or reactive fluids. Doing so will likely result in poor performance, seal failure, or permanent damage.

Making the Right Choice for Your Application

Managing the liquid medium correctly is the single most important factor in achieving reliable results with your pump.

- If your primary focus is general lab use for filtration: Use clean tap water and change it weekly or whenever it appears cloudy to ensure consistent performance.

- If your primary focus is evacuating systems with corrosive vapors: You must shorten the water replacement cycle significantly, changing it daily or even after each procedure to protect the pump.

- If your primary focus is achieving the deepest possible vacuum: Use fresh, cold water for every operation, as this will minimize vapor pressure and maximize pump efficiency.

Proper management of the circulating water is the key to unlocking the consistent and reliable performance of your vacuum pump.

Summary Table:

| Medium Type | Key Properties | Common Applications |

|---|---|---|

| Water | Low vapor pressure, low viscosity, chemically inert | General lab use, filtration |

| Similar Liquids | Must mimic water's properties | Specialized setups requiring substitutes |

| Avoided Fluids | Oils, solvents, reactive liquids | Prevents pump damage and failure |

Unlock Reliable Vacuum Performance with KINTEK's Custom Solutions!

Struggling with pump inefficiencies or corrosive gas handling in your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we precisely meet your unique experimental needs, enhancing efficiency and durability.

Contact us today to discuss how our tailored products can optimize your vacuum pump operations and boost your lab's productivity!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What role does a molecular pump set play in an electric current-assisted TLP bonding system? Enhance Vacuum Purity

- What are the core functions of high-purity graphite molds and graphite paper in SPS? Optimize Sintering Quality

- What role does a ceramic crucible play in oxidation weight gain experiments for Ti-V-Cr alloys? Ensure Data Accuracy

- What are tube furnace tubes made of? Select the Right Material for Your Process

- What maintenance is required for a water circulating vacuum pump? Ensure Peak Performance and Longevity

- Why must the reaction containers be sealed within a fused quartz tube? Protect Your Crystal Growth Integrity

- What are the reasons for using high-purity alumina material for the reaction tubes in a Drop Tube Furnace? - Guide

- What are the advantages of high-temperature BSE detectors? Unlock Real-Time Compositional Analysis up to 1000°C