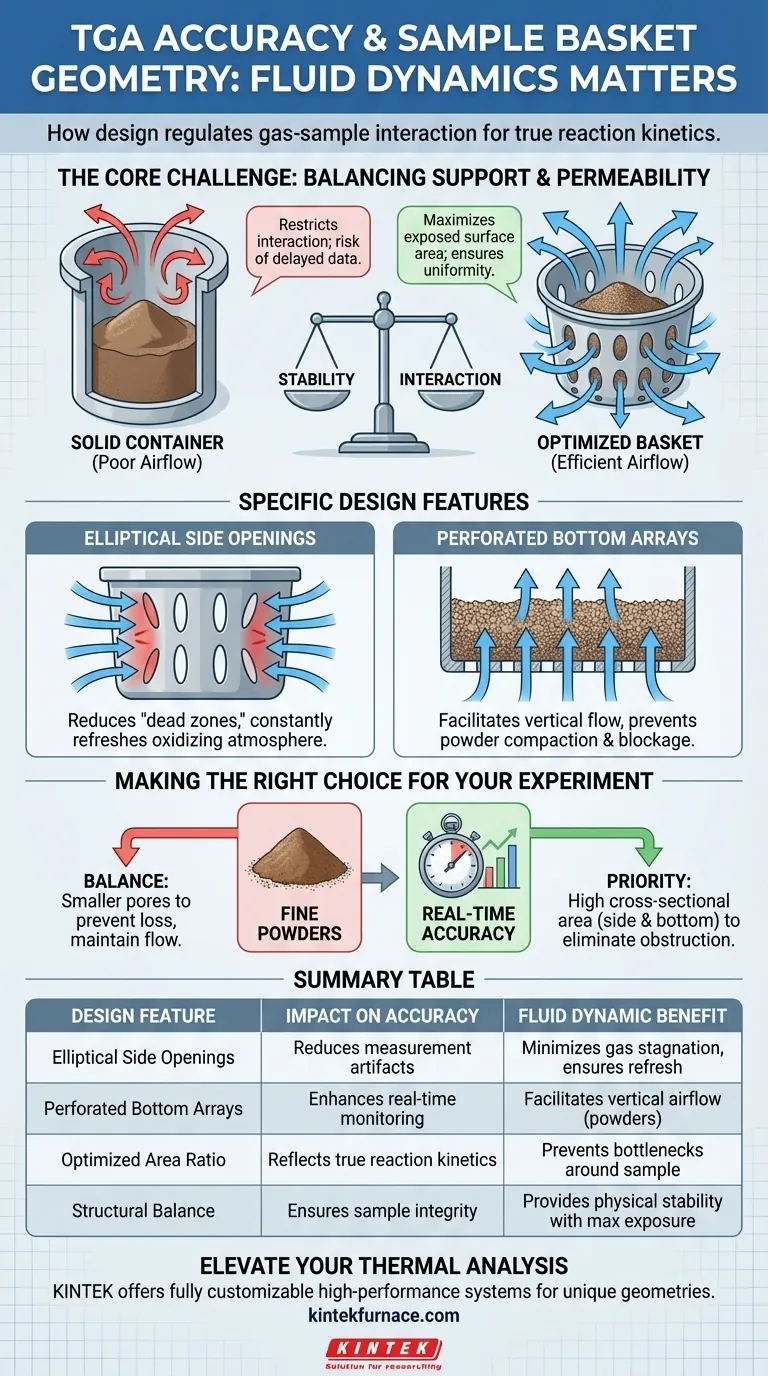

The geometric design of a sample basket significantly influences measurement accuracy by regulating how the oxidizing agent interacts with the material. Features such as elliptical side openings and perforated bottom arrays are engineered to optimize fluid dynamics. This specific geometry minimizes airflow obstruction, ensuring that the mass loss data recorded during thermogravimetric analysis reflects the true reaction kinetics rather than artifacts caused by poor gas circulation.

Accurate thermogravimetric analysis relies on striking a precise balance between physical stability and aerodynamic efficiency. The basket design must support the sample securely while maximizing the effective cross-sectional area for airflow to prevent blockages that distort real-time data.

The Role of Geometry in Fluid Dynamics

Balancing Support and Permeability

The core challenge in basket design is supporting the sample—such as waste coffee powder—while allowing the oxidizing agent (like air) to permeate freely.

A solid container provides maximum support but restricts gas interaction to the top surface only. Conversely, a highly open structure maximizes flow but risks sample loss.

The ideal geometry uses specific cutouts to maintain structural integrity while significantly increasing the surface area exposed to the gas flow.

Preventing Airflow Obstruction

When airflow is obstructed by the basket walls or floor, the oxidation process becomes inconsistent.

This inconsistency leads to delayed or uneven mass loss readings, which do not accurately represent the sample's thermal behavior.

By maintaining an appropriate cross-sectional area ratio, the design prevents these bottlenecks, ensuring the oxidizing agent reaches the sample uniformly.

Specific Design Features and Their Impact

Elliptical Side Openings

The inclusion of elliptical openings on the sides of the basket is a strategic choice for managing fluid dynamics.

These openings allow air to enter from multiple angles, reducing the "dead zones" where gas stagnation might occur.

This ensures that the oxidizing atmosphere is constantly refreshed around the sample, leading to more reliable monitoring.

Perforated Bottom Arrays

The bottom of the basket is often the area of greatest airflow resistance in standard designs.

Implementing a perforated array at the base allows the oxidizing agent to flow upward through the sample mass.

This vertical flow is critical for obtaining real-time accuracy, particularly for granular or powder samples that might otherwise compact and block air passage.

Understanding the Trade-offs

The Stability vs. Interaction Conflict

While increasing the open area of a basket improves airflow, it introduces potential risks regarding sample containment.

If the perforations or openings are too large relative to the particle size of the sample (e.g., fine powders), material may fall through or become dislodged.

Therefore, the "optimization" mentioned in the design is a calculated compromise: maximizing openings only up to the point where sample stability is compromised.

Making the Right Choice for Your Experiment

To ensure the validity of your thermogravimetric data, you must match the basket geometry to your specific analytical needs.

- If your primary focus is real-time mass loss accuracy: Prioritize baskets with high cross-sectional area ratios, such as those with side and bottom perforations, to eliminate airflow obstruction.

- If your primary focus is analyzing fine powders: Select a design that balances aerodynamic openings with sufficiently small pore sizes to prevent physical sample loss while maintaining flow efficiency.

By treating the sample basket as an active component of the fluid dynamic system rather than a passive holder, you ensure the fidelity of your thermal analysis data.

Summary Table:

| Design Feature | Impact on Accuracy | Fluid Dynamic Benefit |

|---|---|---|

| Elliptical Side Openings | Reduces measurement artifacts | Minimizes gas stagnation zones and ensures gas refresh |

| Perforated Bottom Arrays | Enhances real-time monitoring | Facilitates vertical airflow through granular or powder samples |

| Optimized Area Ratio | Reflects true reaction kinetics | Prevents airflow obstruction and bottlenecks around the sample |

| Structural Balance | Ensures sample integrity | Provides physical stability while maximizing surface area exposure |

Elevate Your Thermal Analysis with Precision Engineering

Maximize the accuracy of your material characterization with KINTEK’s advanced laboratory solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique experimental geometries and fluid dynamic requirements.

Whether you are analyzing fine powders or complex composites, our high-temperature furnaces and specialized accessories ensure consistent gas circulation and reliable data. Contact us today to discuss how our customizable systems can optimize your research outcomes.

Visual Guide

References

- Beata Brzychczyk, L. J. Sikora. Modernization of a Tube Furnace as Part of Zero-Waste Practice. DOI: 10.3390/su17198940

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What roles do high-purity graphite molds perform in A357 sintering? Enhancing Aluminum Matrix Composite Performance

- What are the primary functions of a quartz tube reactor? Enhance Hydrogen Production and Induction Efficiency

- What is the function of a graphite crucible during the synthesis of LaMg6Ga6S16 crystals? Ensure Purity & Protection

- How does the integration of digital control panels and safety devices enhance industrial electric furnace operation?

- What are the main reasons for the alumina furnace tube being prone to breaking? Prevent Costly Failures with Expert Tips

- What are the primary functions of multilayer fixtures within a lithium battery vacuum oven? Optimize Your Drying Process

- Why use a high-purity alumina crucible with a lid for LATP sintering? Ensure Optimal Stoichiometric Stability

- Why are high-purity alumina crucibles used for phosphor synthesis? Ensure Maximum Luminescence and Spectral Purity