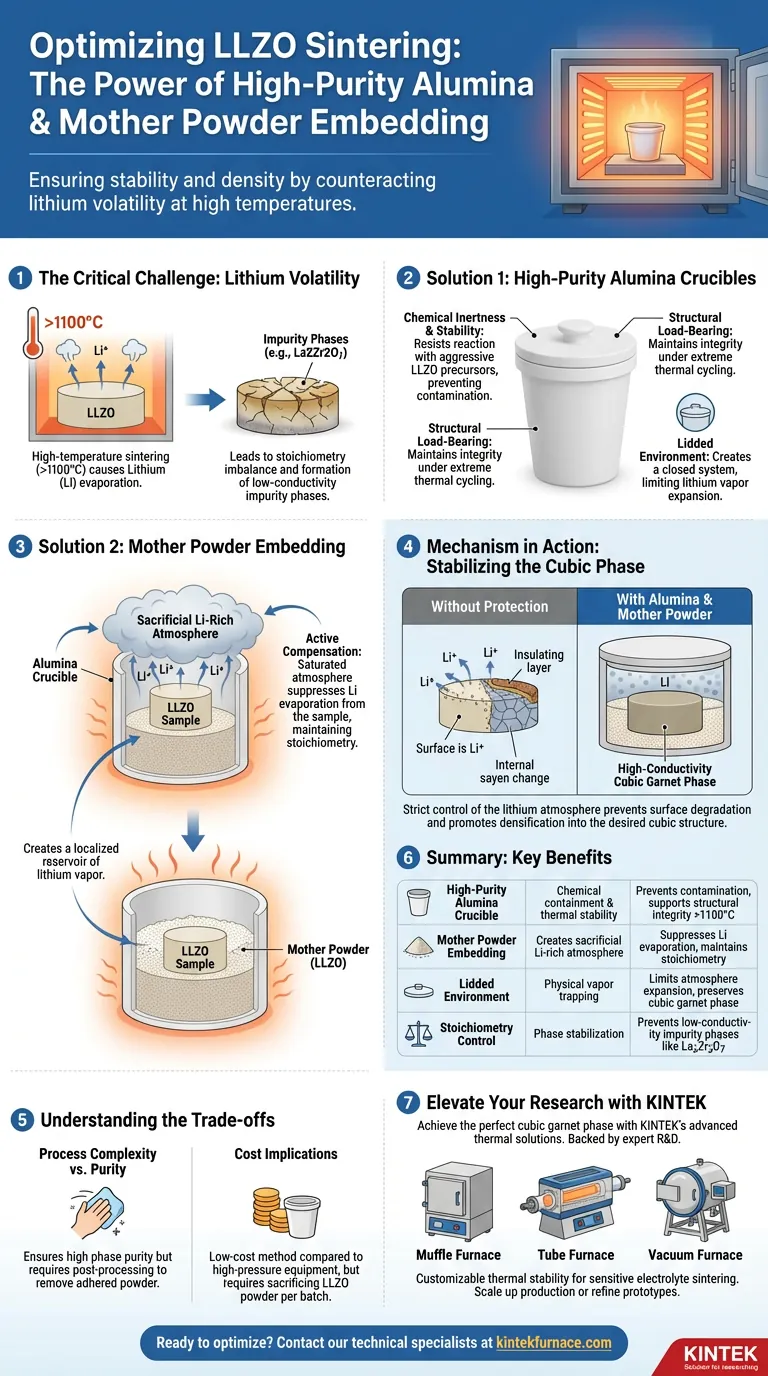

To ensure the stability and density of Li7La3Zr2O12 (LLZO) ceramics, specific processing techniques are required to counteract the volatility of lithium at high temperatures. The use of high-purity alumina crucibles combined with the mother powder embedding method creates a controlled, chemically stable micro-environment that preserves the material's stoichiometry and crystal structure.

Core Takeaway The primary challenge in sintering LLZO is preventing lithium evaporation, which leads to the formation of low-conductivity impurity phases. High-purity alumina crucibles provide a non-reactive containment vessel, while the mother powder embedding method generates a sacrificial lithium vapor atmosphere to actively compensate for loss, ensuring the formation of the highly conductive cubic garnet phase.

The Critical Challenge: Lithium Volatility

The Risk of High-Temperature Sintering

Sintering LLZO requires temperatures often exceeding 1100°C to achieve grain growth and densification. At these temperatures, lithium is highly volatile and prone to evaporation.

Consequences of Lithium Loss

When lithium volatilizes from the sample, the material suffers from a stoichiometry imbalance. This loss triggers the degradation of the desired cubic phase into undesirable secondary phases, most notably La2Zr2O7. These impurity phases are detrimental because they have low ionic conductivity, severely hampering the performance of the final electrolyte.

The Role of High-Purity Alumina Crucibles

Chemical Inertness and Stability

High-purity alumina is selected primarily for its superior chemical stability at extreme temperatures. Unlike other container materials, high-purity alumina resists reacting with the aggressive LLZO precursors, preventing external impurities from leaching into the electrolyte sample.

Structural Load-Bearing

Beyond chemical properties, these crucibles offer excellent high-temperature load-bearing capacity. They maintain their structural integrity during the rigorous heating cycle, ensuring the sample remains mechanically stable while the ceramic densifies.

Containing the Micro-Environment

When used with a lid, alumina crucibles help create a "closed" system. This physical containment limits the volume into which lithium vapor can expand, effectively trapping the atmosphere generated by the bed powder close to the sample.

The Mechanism of Mother Powder Embedding

Creating a Sacrificial Atmosphere

The "mother powder" is simply LLZO powder of the same composition as the sample. By embedding or covering the sample in this powder, you create a localized reservoir of lithium.

Active Compensation

As the system heats up, the mother powder releases lithium vapor. This creates a high-concentration lithium environment around the sample. Because the surrounding atmosphere is already saturated with lithium from the powder, the thermodynamic drive for lithium to evaporate from the sample itself is significantly reduced.

Stabilizing the Cubic Phase

This technique acts as an atmosphere regulator. By suppressing volatilization, the method ensures the sample maintains the correct chemical formula (stoichiometry). This stability prevents the surface from degrading into insulating phases and allows the material to densify into the high-conductivity cubic garnet structure.

Understanding the Trade-offs

Process Complexity vs. Purity

While embedding samples in mother powder ensures high phase purity, it introduces complexity. The sample surface may require post-processing to remove adhered powder or surface roughness caused by the interaction with the bed material.

Cost Implications

Using mother powder is generally considered a low-cost method compared to specialized high-pressure equipment. However, it does require sacrificing a quantity of high-quality LLZO powder for every sintering run, which impacts the total material efficiency and cost per batch.

Making the Right Choice for Your Goal

To optimize your LLZO sintering process, consider the following specific adjustments:

- If your primary focus is preventing impurity phases: Ensure the mother powder completely covers the sample to eliminate any "lean" zones where lithium depletion could trigger the formation of La2Zr2O7.

- If your primary focus is maximizing density: Utilize a lidded alumina crucible to minimize the escape of lithium vapor, allowing for longer sintering times that promote grain growth without degrading the material.

By strictly controlling the lithium atmosphere through these methods, you transform a volatile process into a reproducible pathway for high-performance solid-state electrolytes.

Summary Table:

| Component/Method | Primary Function | Benefit to LLZO Sintering |

|---|---|---|

| High-Purity Alumina Crucible | Chemical containment & thermal stability | Prevents contamination and supports structural integrity at 1100°C+. |

| Mother Powder Embedding | Creates a sacrificial lithium-rich atmosphere | Suppresses lithium evaporation from the sample, maintaining stoichiometry. |

| Lidded Environment | Physical vapor trapping | Limits atmosphere expansion to ensure the cubic garnet phase is preserved. |

| Stoichiometry Control | Phase stabilization | Prevents formation of low-conductivity impurity phases like La2Zr2O7. |

Elevate Your Solid-State Battery Research with KINTEK

Achieving the perfect cubic garnet phase in LLZO requires precision and the right equipment. Backed by expert R&D and world-class manufacturing, KINTEK provides the advanced thermal solutions necessary for sensitive electrolyte sintering.

Our range of Muffle, Tube, and Vacuum furnaces is fully customizable to meet your specific temperature and atmospheric requirements. Whether you are scaling up production or refining laboratory prototypes, KINTEK offers the thermal stability and reliability your materials demand.

Ready to optimize your sintering process? Contact our technical specialists today to find the ideal furnace solution for your lab.

Visual Guide

References

- Degradation mechanisms in low-voltage Wadsley–Roth TiNb<sub>2</sub>O<sub>7</sub> electrodes upon cycling with Li. DOI: 10.1039/d4ta06441k

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the function of ceramic balls within a box furnace? Improve Coke Graphitization & System Safety

- Why are laboratory hydraulic presses critical for FMDS pelletization? Boost Strength Without Heat

- Why are high-purity alumina grinding balls used for Al2O3/TiC milling? Master Chemical Consistency

- How are constant temperature water baths and drying ovens utilized to verify bonding quality? Master EN 314-1 Testing

- Why is a heating device with magnetic stirring required for Y2O3-MgO precursors? Ensure Perfect Particle Coating

- How does a high-precision analog pressure gauge contribute to the gas delivery system in magnesium combustion experiments?

- How many taps does the water circulating vacuum pump have? Choose the Right Model for Your Lab

- What is the primary function of a drying oven during LLZTO preparation? Ensure Pure Phase Solid Electrolytes