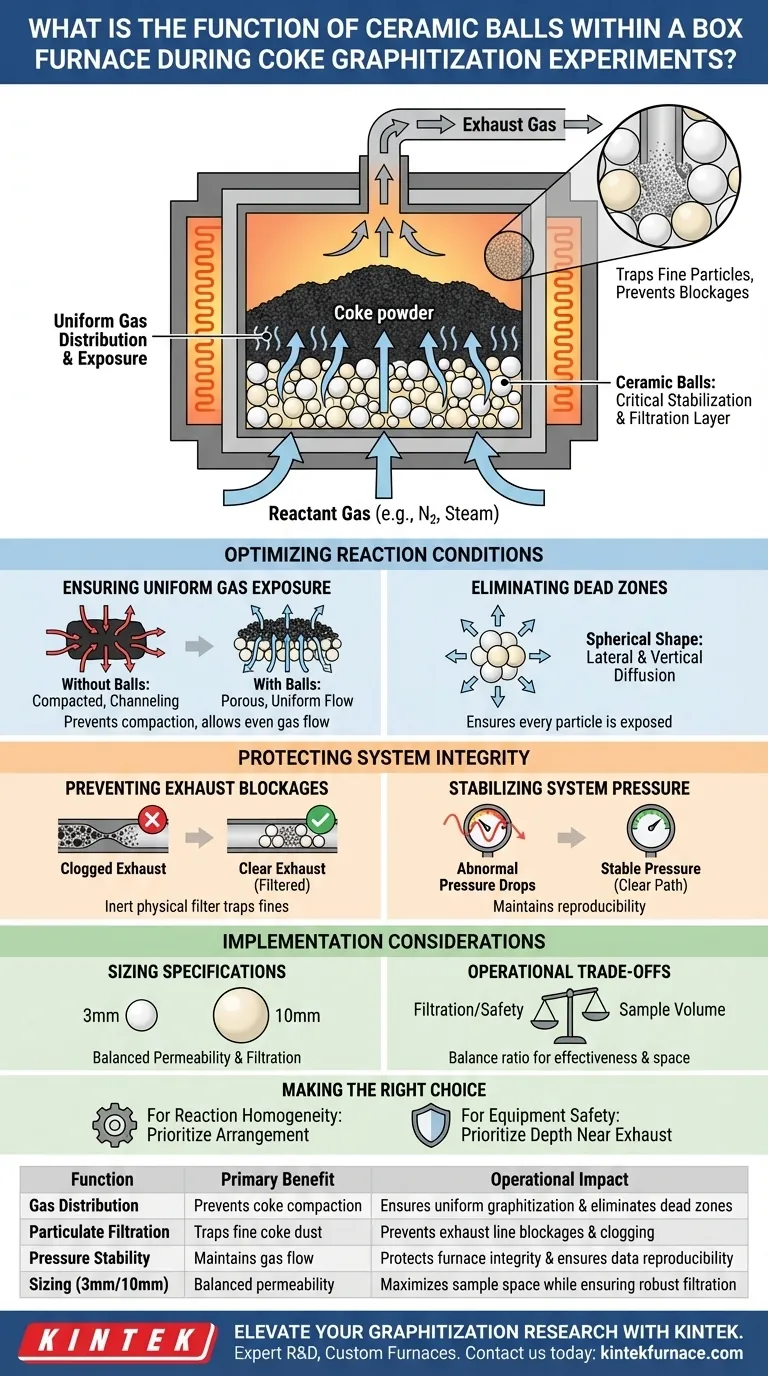

Ceramic balls act as a critical stabilization and filtration layer within box furnaces during coke graphitization experiments. Their primary function is to support the coke powder to ensure uniform gas distribution while simultaneously trapping fine particles to prevent exhaust blockages and pressure anomalies.

By acting as a permeable barrier, ceramic balls solve the dual challenge of inconsistent reaction atmospheres and mechanical system failure. They ensure the reactant gas reaches the entire sample bed while protecting downstream components from particulate contamination.

Optimizing Reaction Conditions

Ensuring Uniform Gas Exposure

Graphitization requires precise control over the reaction atmosphere, utilizing gases such as nitrogen, steam, air, or carbon dioxide.

Ceramic balls prevent the coke powder from compacting into a dense, impermeable mass. This creates a porous structure that allows the gas to flow evenly through the entire sample, rather than channeling through specific paths.

Eliminating Dead Zones

Without a support medium, gas flow can become inconsistent, leading to uneven graphitization.

The spherical shape of the balls forces the gas to diffuse laterally as well as vertically. This ensures that every particle of coke powder is exposed to the requisite thermal and chemical environment.

Protecting System Integrity

Preventing Exhaust Blockages

Coke graphitization generates fine particulate matter that is easily entrained in the gas stream.

Ceramic balls function as an inert physical filter, intercepting these fine particles before they can exit the reaction zone. This prevents the particles from entering and clogging the furnace's exhaust lines.

Stabilizing System Pressure

A clogged exhaust line leads to abnormal pressure drops, which can invalidate experimental data or damage the furnace.

By keeping the exhaust path clear of debris, ceramic balls maintain a stable internal pressure. This stability is essential for the reproducibility of high-temperature experiments.

Implementation Considerations

Sizing Specifications

Standard protocols typically utilize ceramic balls with diameters of 3mm and 10mm.

Using a combination of sizes can help balance the need for adequate gas permeability with the need to trap finer particles.

Operational Trade-offs

While ceramic balls are essential for safety and consistency, they occupy physical volume within the heating zone.

You must balance the ratio of ceramic balls to coke powder. Too few balls may fail to stop clogging; too many will reduce the available space for your sample material.

Making the Right Choice for Your Experiment

To maximize the effectiveness of your graphitization process, consider your specific experimental priorities:

- If your primary focus is Reaction Homogeneity: Prioritize the arrangement of the ceramic balls to ensure the coke powder is loosely packed, maximizing gas contact surface area.

- If your primary focus is Equipment Safety: Ensure you use a sufficient depth of ceramic balls (particularly smaller diameters) near the exhaust path to act as a robust particulate trap.

The correct application of ceramic balls transforms a volatile, clog-prone experiment into a stable, reproducible process.

Summary Table:

| Function | Primary Benefit | Operational Impact |

|---|---|---|

| Gas Distribution | Prevents coke compaction | Ensures uniform graphitization & eliminates dead zones |

| Particulate Filtration | Traps fine coke dust | Prevents exhaust line blockages and clogging |

| Pressure Stability | Maintains gas flow | Protects furnace integrity & ensures data reproducibility |

| Sizing (3mm/10mm) | Balanced permeability | Maximizes sample space while ensuring robust filtration |

Elevate Your Graphitization Research with KINTEK

Precise thermal processing requires more than just a furnace; it requires specialized expertise. At KINTEK, we understand the nuances of material science experiments. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique experimental needs.

Whether you are refining coke graphitization or developing new carbon materials, our team provides the reliable equipment and technical support needed for stable, reproducible results. Contact us today to optimize your lab setup!

Visual Guide

References

- P. Nanthagopal R. Sachithananthan. Analytical Review on Impact of Catalytic Coke Formation on Reactor Surfaces During the Thermal Cracking Process. DOI: 10.5281/zenodo.17985551

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a high-precision DC power supply necessary for PFS? Control Electric Fields for Perfect Plasma Sintering

- Why are insulation ceramic plugs used inside the alumina furnace tube? Ensure Stable Heating and Prevent Tube Cracking

- How does the circulating water vacuum pump work? Uncover the Liquid Piston Mechanism

- What role do graphite molds play in the Spark Plasma Sintering (SPS)? Enhance Alumina Composite Performance

- What is the function of ceramic alumina furnace tubes for Ti–Nb–Si alloys? Key Roles in Sintering & Purity

- What is the purpose of using a high-purity ceramic crucible with a sealed lid during the thermal treatment of biochar?

- What additional convenience feature is included with the water circulating vacuum pump? Discover Easy Mobility and More

- What is the general ambient temperature limit for water circulating vacuum pumps? Ensure Peak Performance and Avoid Damage