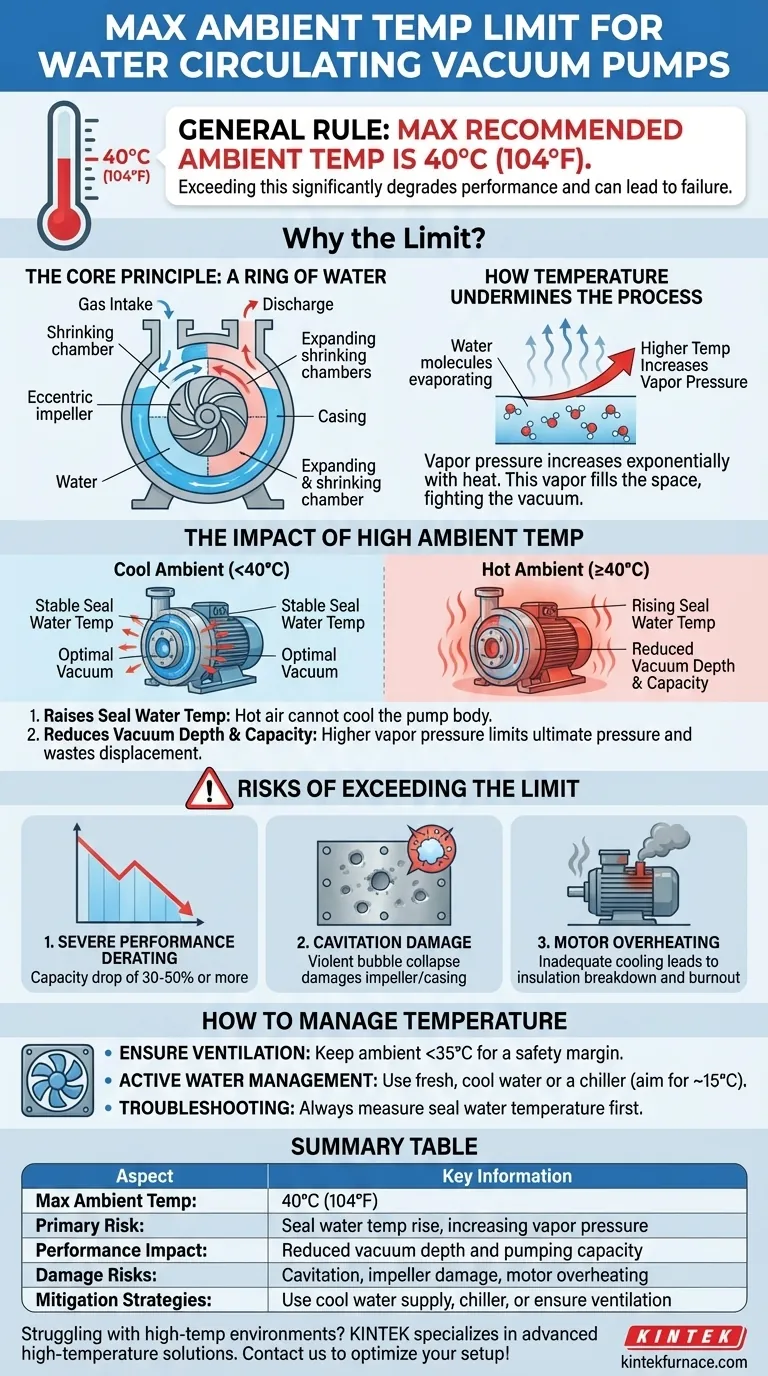

As a general rule, the maximum recommended ambient temperature for a water circulating vacuum pump (also known as a liquid ring vacuum pump) is 40°C (104°F). Operating in an environment hotter than this will significantly degrade the pump's performance and can lead to premature failure.

The 40°C limit is not just about protecting the motor; it is fundamentally about the physics of creating a vacuum. The pump's performance is directly tied to the temperature of its sealing water, which is heavily influenced by the surrounding air temperature.

The Link Between Ambient Air and Vacuum Creation

To understand the temperature limitation, you must first understand how a liquid ring pump works. Its operation is a simple, robust mechanical process that is highly dependent on temperature.

The Core Principle: A Ring of Water

A liquid ring vacuum pump uses a spinning impeller, eccentrically mounted within a cylindrical casing. As it spins, centrifugal force throws a sealant liquid (usually water) against the outer wall of the casing, forming a stable, concentric "liquid ring."

Because the impeller is off-center, the space between the impeller hub and the liquid ring continuously changes. This creates expanding "chambers" that draw in gas and shrinking chambers that compress and discharge it, creating the vacuum.

How Temperature Undermines the Process

The vacuum is created in the empty space between the impeller and the water. However, this space is never truly empty—it is filled with the vapor of the sealant liquid itself.

The temperature of the water determines its vapor pressure. As water gets warmer, it evaporates more readily, and its vapor pressure increases exponentially. This water vapor acts as a gas that fills the very space you are trying to evacuate, directly fighting against the vacuum you want to create.

The Impact of High Ambient Temperature

A high ambient temperature cripples a liquid ring pump in two primary ways: by heating the seal water and by overheating the pump's mechanical components.

It Raises the Seal Water Temperature

The pump generates heat during compression, and the entire pump body dissipates this heat into the surrounding air. If the ambient air is already hot (approaching 40°C), it cannot effectively cool the pump.

This causes the seal water temperature to rise steadily during operation. As the water temperature climbs, its vapor pressure skyrockets, leading to a cascade of performance issues.

It Reduces Vacuum Depth

The ultimate pressure a pump can achieve is limited by the vapor pressure of its seal liquid. If your seal water heats up to 30°C (86°F), its vapor pressure is about 32 mbar. The pump simply cannot produce a vacuum deeper than that, no matter how long it runs.

It Decreases Pumping Capacity

Higher vapor pressure not only limits the final vacuum level but also reduces the pump's effective capacity. The pump wastes a portion of its volumetric displacement just moving its own water vapor, leaving less capacity available to move your process gas.

Understanding the Trade-offs and Risks

Exceeding the recommended ambient temperature is not a soft guideline; it has direct, measurable consequences.

Risk 1: Severe Performance Derating

A pump's performance curve is typically rated with 15°C (60°F) seal water. For every degree the water temperature rises, you can expect a noticeable drop in performance. Operating in a 40°C environment can easily cut a pump's capacity by 30-50% or more, especially at deeper vacuum levels.

Risk 2: Cavitation Damage

Cavitation occurs when the pressure inside the pump drops below the water's vapor pressure, causing the water to spontaneously boil. This creates vapor bubbles that collapse violently when they move to a higher-pressure zone.

This collapse is powerful enough to chip away at the impeller and pump casing, leading to noise, vibration, and eventual catastrophic failure. Higher water temperature makes cavitation far more likely.

Risk 3: Motor Overheating and Failure

The pump's electric motor also relies on the ambient air for cooling. In a high-temperature environment, the motor may not be able to dissipate its own heat, leading to the breakdown of winding insulation and a complete motor burnout.

How to Apply This to Your System

Your strategy for managing temperature depends entirely on your performance requirements and operating environment.

- If your primary focus is reliability and consistent performance: Ensure your pump is in a well-ventilated area with ambient temperatures consistently below 35°C (95°F) to provide a safety margin.

- If you must operate in an environment near or above 40°C (104°F): You must actively manage the seal water temperature. Do not rely on recirculation; instead, supply a constant flow of fresh, cool water or use a chiller to keep the seal water temperature at its specified level (often 15°C / 60°F).

- If you are troubleshooting poor vacuum performance: Before inspecting the pump for mechanical failure, measure your ambient temperature and, more importantly, your seal water temperature. An unexpectedly high temperature is the most common cause of a "weak" vacuum pump.

Ultimately, controlling temperature is the single most important factor in ensuring your liquid ring vacuum pump performs to its specification.

Summary Table:

| Aspect | Key Information |

|---|---|

| Max Ambient Temperature | 40°C (104°F) |

| Primary Risk | Seal water temperature rise, increasing vapor pressure |

| Performance Impact | Reduced vacuum depth and pumping capacity |

| Damage Risks | Cavitation, impeller damage, motor overheating |

| Mitigation Strategies | Use cool water supply, chiller, or ensure ventilation |

Struggling with vacuum pump performance in high-temperature environments? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique lab needs, ensuring reliability and efficiency. Contact us today to discuss how we can optimize your setup and prevent costly failures!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the function of a vacuum pump in tantalum capacitor recycling? Optimize Purity and Speed

- What are the preparation steps for a water circulating vacuum pump? Ensure Optimal Performance and Longevity

- Why are fly ash geopolymer specimens subjected to 60 °C drying? Master Accelerated Curing for Maximum Strength

- Why is a semi-closed alumina crucible required for g-C3N4? Maximize Your Synthesis Yield and Quality

- Why are alumina ceramic tubes preferred for high-temperature furnaces? Ensure Stability and Control Up to 1800°C

- What role do high-purity graphite molds and punches play during the sintering of silicon carbide ceramics in SPS?

- What is the significance of high-precision mass flow controllers in testing NiFe2O4? Ensure Data Integrity

- How does the purity of alumina ceramic tubes compare to quartz ceramic tubes? Discover Key Differences for Your Lab