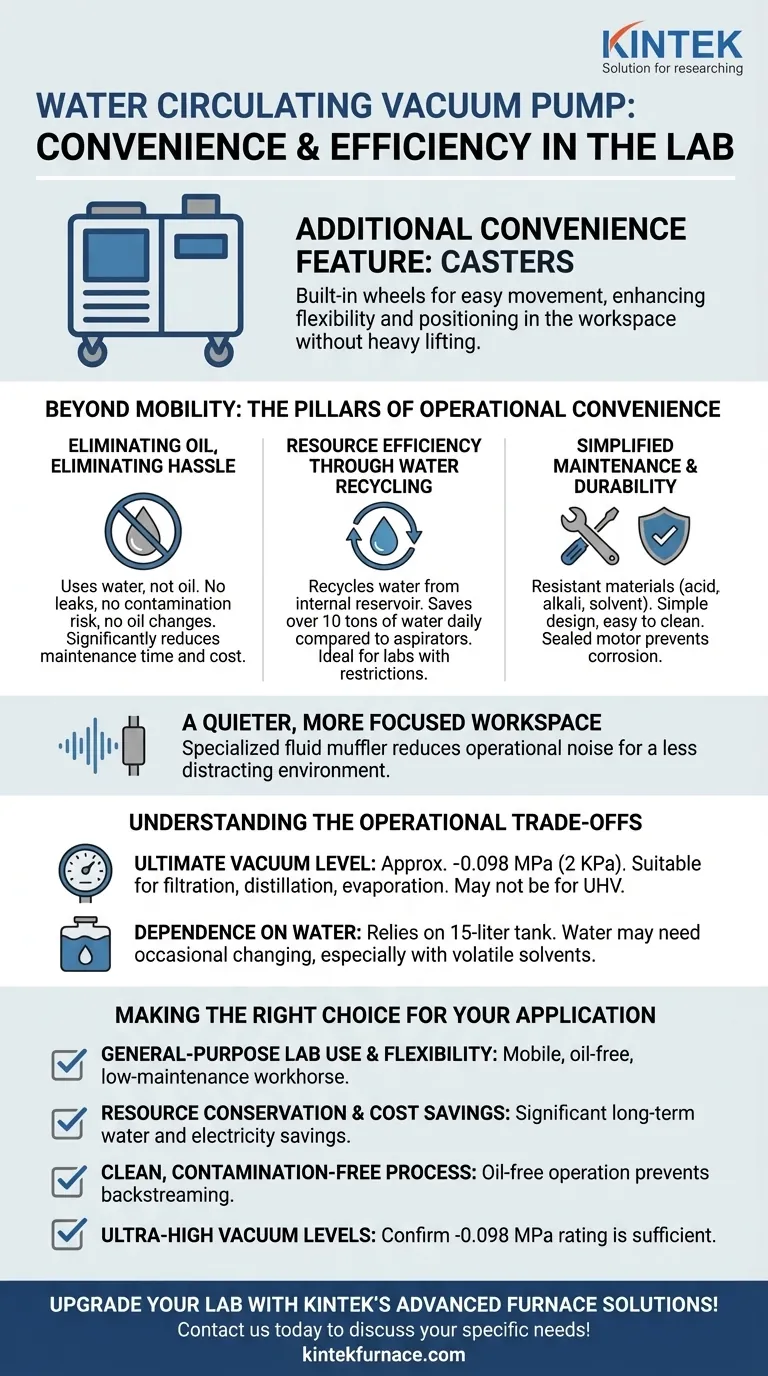

To put it directly, the most common additional convenience feature included with a water circulating vacuum pump is a set of casters. This simple addition allows the unit to be moved easily around a laboratory or workspace, enhancing its flexibility and making it simple to position where needed without heavy lifting.

While casters provide physical mobility, the true convenience of a water circulating vacuum pump lies in its fundamental design: it is an oil-free, water-recycling, and low-maintenance system that simplifies daily laboratory operations.

Beyond Mobility: The Pillars of Operational Convenience

The convenience of this pump extends far beyond its physical mobility. The core technology is engineered to reduce the common points of friction and maintenance associated with traditional vacuum systems.

Eliminating Oil, Eliminating Hassle

Unlike many mechanical pumps, a water circulating vacuum pump uses water as its working medium. This completely eliminates the need for oil.

This oil-free design means there are no oil leaks to manage, no risk of oil contaminating your vacuum system or experiment, and no need to perform routine oil changes. This significantly reduces maintenance time and cost.

Resource Efficiency Through Water Recycling

A primary feature is its ability to recycle water from an internal reservoir. The pump continuously reuses the same water to generate a vacuum.

This contrasts sharply with aspirators that connect directly to a tap, which can waste enormous amounts of water. In one working day, this pump can save over 10 tons of water, making it not only economical but also ideal for labs with water restrictions.

Simplified Maintenance and Durability

These pumps are often built with materials resistant to acid, alkali, and solvents, increasing their durability in a typical lab environment.

The design is inherently simple compared to complex oil pumps, making it easy to use and clean. The high-quality motor is often sealed to prevent corrosion from any ingested gases.

A Quieter, More Focused Workspace

Many models include a specialized fluid muffler. This feature is designed specifically to reduce operational noise.

A quieter pump contributes to a less distracting and more productive work environment, a practical benefit that is often overlooked when evaluating equipment.

Understanding the Operational Trade-offs

To make a fully informed decision, it's crucial to understand the context in which this pump excels and its potential limitations.

Ultimate Vacuum Level

The pump is designed to achieve an ultimate vacuum of approximately -0.098 MPa (2 KPa). This is sufficient for a vast range of common laboratory applications like filtration, distillation, and evaporation.

However, for ultra-high vacuum (UHV) applications, this level may not be adequate. Always verify that its vacuum capability meets the specific requirements of your process.

Dependence on Water

The system's performance relies on the water in its 15-liter tank. While recycling is a major benefit, the water may need to be occasionally changed, especially if volatile solvents are being evacuated, to maintain optimal vacuum pressure and prevent contamination buildup.

Making the Right Choice for Your Application

Choosing the right pump means aligning its features with your primary goals.

- If your primary focus is general-purpose lab use and flexibility: The mobile, oil-free, and low-maintenance design makes this pump an ideal and user-friendly workhorse.

- If your primary focus is resource conservation and cost savings: The water-recycling system provides significant long-term savings on both water and electricity.

- If your primary focus is a clean, contamination-free process: The oil-free operation ensures that no pump oil can backstream into your experiment or vacuum chamber.

- If your primary focus is achieving ultra-high vacuum levels: You must confirm that its -0.098 MPa rating is sufficient for your needs before committing.

Ultimately, understanding these practical conveniences allows you to select a tool that not only performs its function but actively improves your workflow.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Casters | Built-in wheels for easy movement | Enhances lab flexibility and positioning |

| Oil-Free Design | Uses water as the working medium | Eliminates oil leaks, reduces maintenance, and prevents contamination |

| Water Recycling | Reuses water from an internal reservoir | Saves over 10 tons of water daily, ideal for restricted labs |

| Simplified Maintenance | Resistant materials and easy cleaning | Increases durability and reduces downtime |

| Specialized Fluid Muffler | Reduces operational noise | Creates a quieter, more productive workspace |

| Ultimate Vacuum Level | Approximately -0.098 MPa (2 KPa) | Suitable for filtration, distillation, and evaporation |

Upgrade your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and performance. Contact us today to discuss how we can support your specific needs!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a high-purity Alumina Crucible required during the annealing of MoS2? Ensure High-Temperature Material Purity

- Why is a high-precision Mass Flow Controller necessary for E-Ni/m-MgAlOx catalysts? Ensure Precise Gas Dynamics

- Why is an alundum crucible necessary for the melting and casting of FeAl alloys? Ensure Maximum Purity and Stability

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis

- What role does a Molybdenum Boat play in ZTO thin film deposition? Master Thermal Evaporation Success

- What are the functions of Silica Quartz Tubes and quartz glass wool in RDF pyrolysis? Enhancing Experimental Accuracy

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation