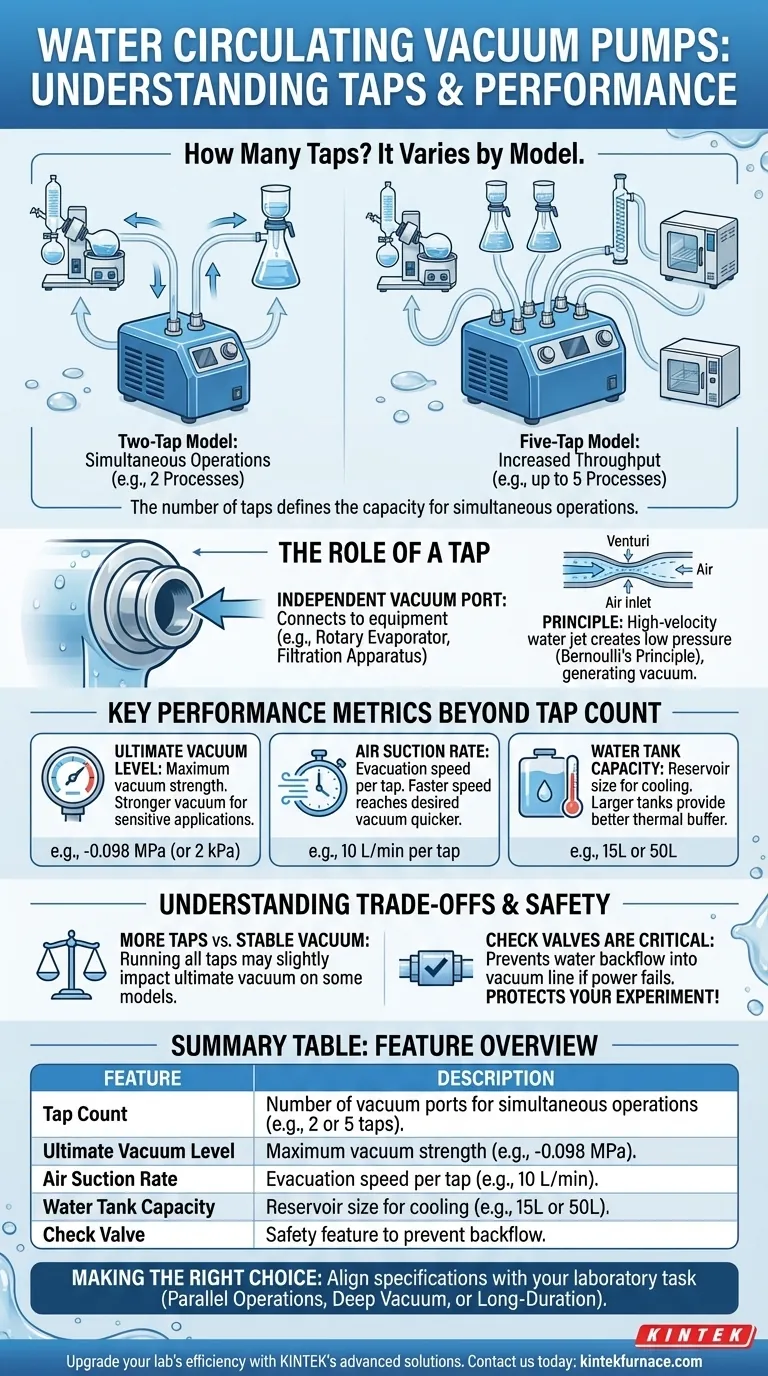

To be direct, the number of taps on a water circulating vacuum pump is not fixed; it varies by model. Common configurations mentioned in technical specifications include both two-tap and five-tap models. The specific pump you are evaluating will have its number of taps listed as a key feature, as this defines its capacity for simultaneous operations.

The number of taps on a vacuum pump indicates how many separate vacuum lines it can support at once. However, this count is only one part of the equation; true performance is determined by the interplay between the number of taps, the ultimate vacuum level, and the air suction rate per tap.

What is the Role of a Tap on a Vacuum Pump?

The taps on a water circulating vacuum pump are the connection points for creating a vacuum. Understanding their function is key to using the pump effectively in a laboratory setting.

Each Tap is an Independent Vacuum Port

Each tap serves as an outlet that can be connected via tubing to a piece of equipment, such as a rotary evaporator, a filtration apparatus, or a distillation setup. A five-tap pump allows a user to run up to five separate vacuum-dependent processes at the same time from a single unit.

The Principle of Operation

These pumps use circulating water as their working fluid. A high-velocity jet of water passes through a venturi, which creates a region of low pressure according to Bernoulli's principle. This negative pressure is what creates the vacuum, which is then made available at each tap.

The pump also often provides recirculated cooling water, making it a dual-purpose utility for many labs.

Key Performance Metrics Beyond Tap Count

While the number of taps is important for throughput, other specifications dictate the quality and speed of the vacuum you can achieve.

Ultimate Vacuum Level

This is the maximum vacuum the pump can generate, often measured in megapascals (MPa) or kilopascals (kPa). A typical specification like -0.098 MPa (or 2 kPa) indicates a very strong vacuum, suitable for most common laboratory applications like evaporation and filtration.

Air Suction Rate

This metric, often listed as liters per minute (L/min) per tap, measures how quickly the pump can evacuate air from a container. A rate of 10 L/min per tap means it can remove 10 liters of air every minute through a single port, which determines how fast your system reaches the desired vacuum.

Water Tank Capacity and Flow

Specifications like a 15L or 50L tank and an 80 L/min flow rate relate to the pump's ability to operate continuously and serve as a cooling system. A larger tank provides a greater thermal buffer, ensuring the water temperature remains stable for longer, which in turn keeps the vacuum level consistent.

Understanding the Trade-offs

Choosing a pump is not as simple as picking the one with the most taps. There are inherent trade-offs to consider for any given model.

More Taps vs. Stable Vacuum

While a multi-tap pump offers great utility, running all taps simultaneously can place a high demand on the system. On some models, this may slightly impact the ultimate vacuum level achievable at each individual port if the total suction demand exceeds the pump's core capacity.

The Importance of Check Valves

A critical safety feature mentioned in pump specifications is a check valve. This device prevents water from the pump from being sucked back into your vacuum line and experiment if the power is suddenly cut. This protects your sample and equipment from contamination and damage.

Efficiency and Water Consumption

Water vacuum pumps are generally not highly efficient, with typical ratings around 30% to 50%. Because water is the working fluid, its temperature will rise during operation, which can degrade vacuum performance. The pump relies on its reservoir of water to dissipate this heat, but for long runs, the water may need to be cooled or replaced.

Making the Right Choice for Your Goal

To select the appropriate pump, you must align its specifications with your primary laboratory task.

- If your primary focus is running multiple, parallel operations (e.g., several filtration setups): A model with more taps (like a five-tap version) is the most efficient choice for your workflow.

- If your primary focus is achieving a deep, stable vacuum for a single sensitive application (e.g., a rotary evaporator): A two-tap model is often sufficient, but you must prioritize a high ultimate vacuum rating (-0.098 MPa or better) and a good suction rate.

- If your primary focus is long-duration experiments requiring both vacuum and cooling: Pay close attention to the water tank capacity (larger is better) and ensure the pump includes safety check valves.

Ultimately, evaluating a pump based on its complete performance profile—not just the tap count—is how you make an informed and effective decision.

Summary Table:

| Feature | Description |

|---|---|

| Tap Count | Number of vacuum ports for simultaneous operations (e.g., 2 or 5 taps) |

| Ultimate Vacuum Level | Maximum vacuum strength, e.g., -0.098 MPa |

| Air Suction Rate | Evacuation speed per tap, e.g., 10 L/min |

| Water Tank Capacity | Reservoir size for cooling, e.g., 15L or 50L |

| Check Valve | Safety feature to prevent backflow |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can support your vacuum and heating applications!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role do quartz tubes play in semiconductor manufacturing? Essential for Purity and High-Temp Processes

- Why are alumina or ceramic crucibles selected for KCdCl3 perovskite? Ensure High Purity and Thermal Stability

- What is the technical value of using a narrowband infrared pyrometer? Expert Precision for High-Temp Measurement

- Why use high-purity MgO crucibles at 1400°C? Secure Chemical Isolation and Data Integrity in Desulfurization

- What are the main types of laboratory furnaces? Find Your Perfect High-Temperature Solution

- Why is firing cotton used as a cushion between the ceramic sample and the tray during sintering? Prevent Distortion

- What is the purpose of a water-cooled condenser in a thermal vacuum mercury removal apparatus? Key for Safe Recovery

- Why is an external cooling system vital for high-temperature furnace stability? Protect Your Research Integrity