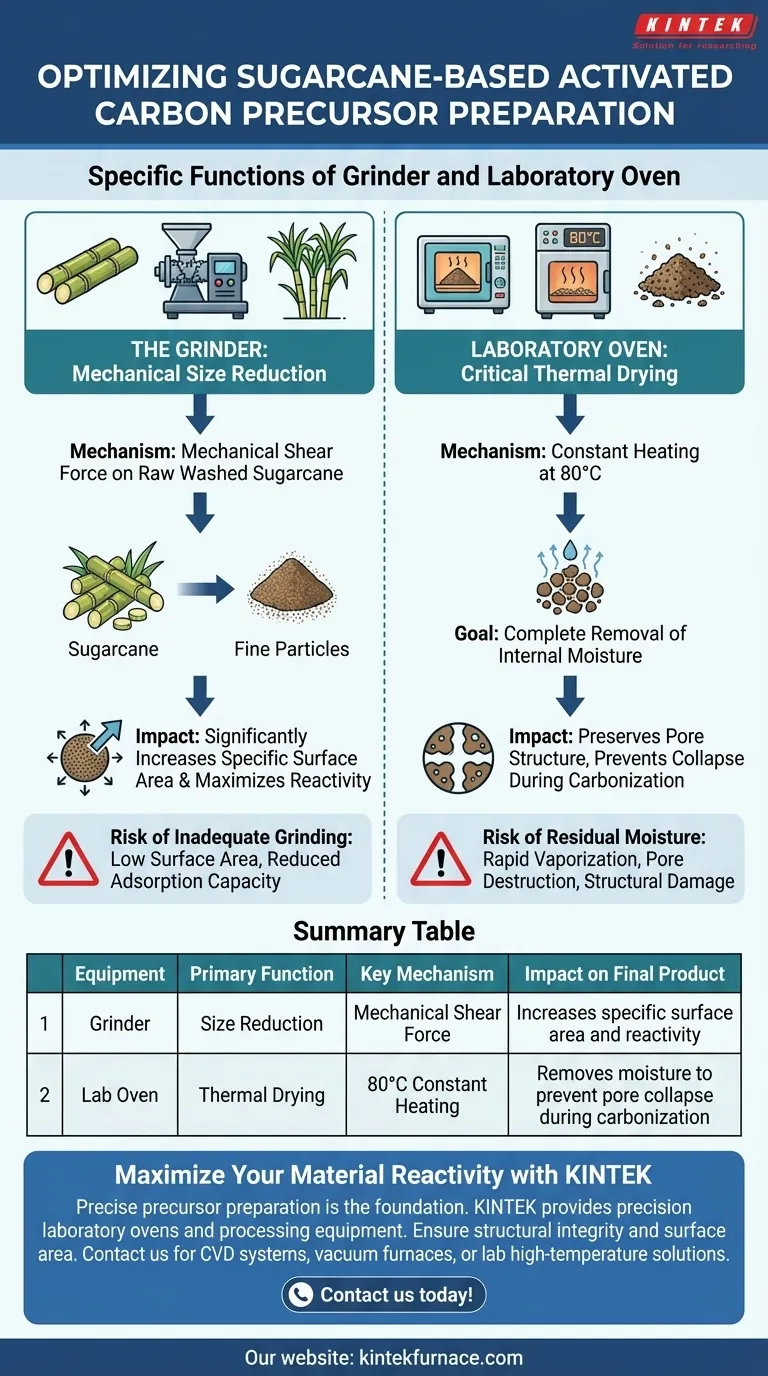

The specific functions of the grinder and laboratory oven are mechanical size reduction and critical moisture elimination. during the precursor phase. The grinder utilizes mechanical shear force to process washed sugarcane into fine particles, directly increasing the specific surface area available for future reactions. The laboratory oven operates at 80°C to remove internal moisture, a vital step that stabilizes the biomass structure against damage during later high-temperature processing.

Success in activated carbon production relies on properly conditioning the raw biomass. The grinder maximizes the material's reactivity by increasing surface area, while the oven prevents the catastrophic collapse of pore structures by removing water before carbonization.

The Role of Mechanical Size Reduction

Mechanism of Action

The grinder serves as the primary tool for physical conditioning. It applies mechanical shear force to the raw, washed sugarcane.

This mechanical action breaks down the fibrous biomass into fine particles.

Impact on Surface Area

The creation of fine particles is not merely for handling purposes; it is a chemical necessity. By reducing particle size, the grinder significantly increases the material's specific surface area.

This increased surface area exposes more of the biomass, making it highly receptive to subsequent reactions in the activation process.

The Criticality of Thermal Drying

Moisture Removal Strategy

Following the grinding process, the laboratory oven is employed to dry the material at a controlled temperature of 80°C.

The specific goal of this phase is the complete removal of internal moisture trapped within the biomass matrix.

Preserving Pore Structure

This drying step is a preventative measure against structural damage. If moisture remains in the precursor, the high temperatures used in the subsequent carbonization stage would cause rapid water vaporization.

Rapid vaporization creates internal pressure that can lead to the collapse of the material's pore structure. By pre-drying the material, the oven ensures the internal architecture remains intact for activation.

Risks of Improper Processing

The Cost of Inadequate Grinding

If the grinder fails to produce sufficiently fine particles, the specific surface area will remain low.

This limits the efficiency of subsequent reactions, potentially resulting in activated carbon with lower adsorption capacity.

The Danger of Residual Moisture

Skipping the drying stage or failing to maintain 80°C can compromise the final product's quality.

Entering carbonization with wet biomass triggers rapid vaporization (steam generation), which mechanically destroys the pores necessary for activated carbon to function.

Optimizing the Precursor Stage

To ensure the production of high-quality sugarcane-based activated carbon, prioritize the following control points:

- If your primary focus is Maximizing Reactivity: Ensure the grinder applies sufficient shear force to produce fine, consistent particles with high surface area.

- If your primary focus is Structural Integrity: Strictly maintain the laboratory oven at 80°C until all internal moisture is removed to prevent pore collapse during carbonization.

Proper precursor preparation transforms raw waste into a stable, highly reactive foundation for advanced carbon materials.

Summary Table:

| Equipment | Primary Function | Key Mechanism | Impact on Final Product |

|---|---|---|---|

| Grinder | Size Reduction | Mechanical Shear Force | Increases specific surface area and reactivity |

| Lab Oven | Thermal Drying | 80°C Constant Heating | Removes moisture to prevent pore collapse during carbonization |

Maximize Your Material Reactivity with KINTEK

Precise precursor preparation is the foundation of high-performance activated carbon. Backed by expert R&D and world-class manufacturing, KINTEK provides the precision laboratory ovens and processing equipment needed to ensure your biomass maintains its structural integrity and surface area.

Whether you require specialized CVD systems, vacuum furnaces, or customizable lab high-temperature solutions, our team is ready to support your unique research and production goals.

Ready to optimize your carbonization process? Contact us today to find the perfect equipment for your lab!

Visual Guide

References

- Yanan Zhao, Jian Wang. Magnetically recoverable bagasse-activated carbon composite anodes for sediment microbial fuel cells: enhanced performance in chromium-contaminated soil remediation. DOI: 10.1039/d5ra02890f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What role does a heat-resistant steel retort play in sintering? Mastering Isolation and Pressure for High-Purity Results

- What kind of experimental environment is provided by a stainless steel vacuum process chamber? Ensure Data Purity

- What are the typical size ranges available for quartz tubes used in laboratory furnaces? Find Your Perfect Fit for High-Temp Applications

- What is the key role of a graphite crucible in the vacuum distillation process for magnesium purification? Essential for High-Purity Results

- What are the placement requirements for high-precision standard thermocouples? Master Sensor Calibration Accuracy

- What are the primary functions of high-purity graphite crucibles? Optimize Mg-Zn-xSr Alloy Purity and Efficiency

- How does an Aluminum Oxide Crucible ensure MXene purity? Key Role of LSS Etching Protection

- What is the function of alumina crucibles in YBCO synthesis? Ensure Purity & Stability in Superconductor Production