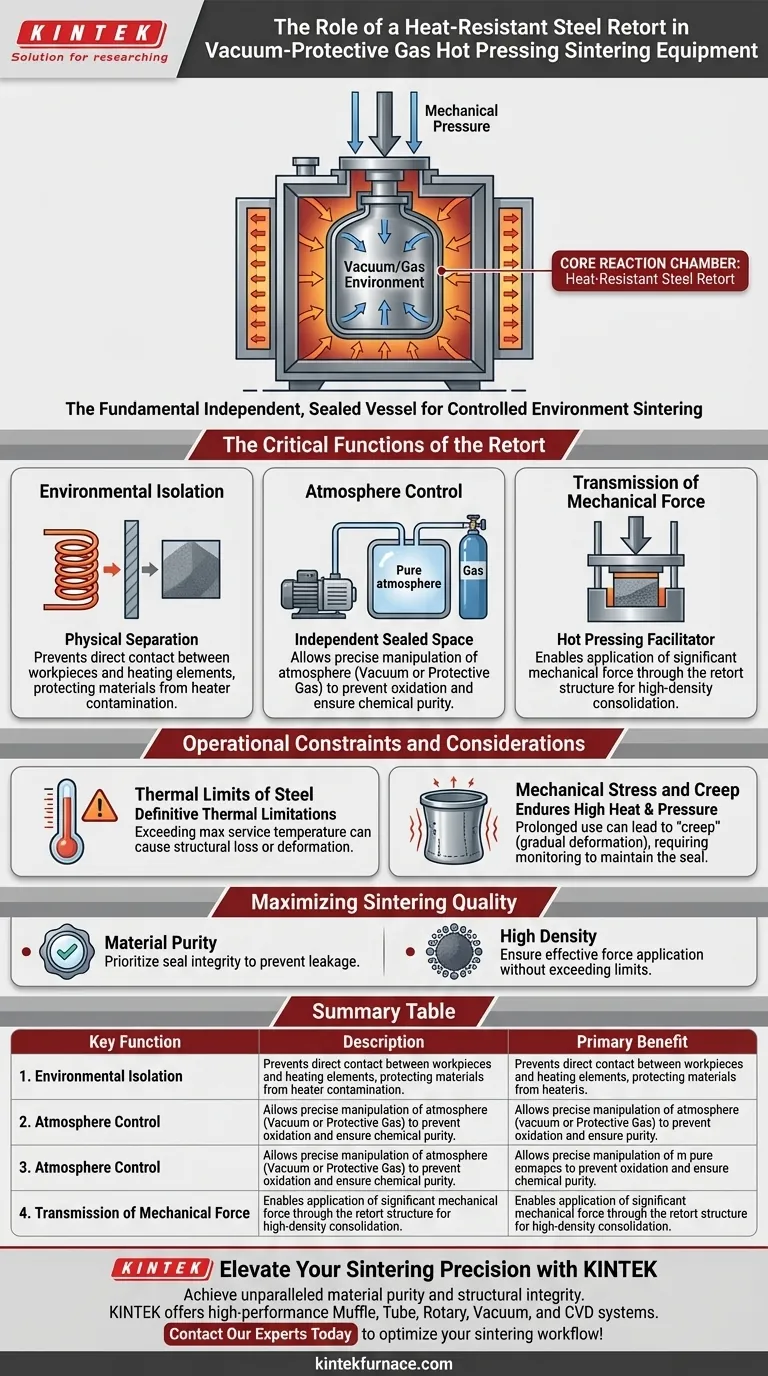

The heat-resistant steel retort serves as the fundamental "core reaction chamber" within vacuum-protective gas hot pressing sintering equipment. It acts as an independent, sealed vessel that physically isolates the workpieces from the external heating elements. This separation is critical for establishing a controlled vacuum or protective gas environment while allowing mechanical pressure to be applied directly to the materials inside.

The retort is the system's primary barrier; it ensures sintering purity by maintaining a sealed atmosphere independent of the heating source, enabling the simultaneous application of heat and pressure.

The Critical Functions of the Retort

Environmental Isolation

The primary function of the retort is to create a distinct boundary between the furnace's heating zone and the material processing zone.

By isolating the workpieces, the retort prevents direct contact with the heating elements, which protects the materials from potential contamination originating from the heater materials.

Atmosphere Control

Because the retort functions as an independent sealed space, it allows for precise manipulation of the atmospheric conditions surrounding the workpiece.

Operators can evacuate the air within the retort to create a vacuum, or fill it with specific protective or reducing gases.

This capability is essential for preventing oxidation and ensuring the chemical purity of the final sintered product.

Transmission of Mechanical Force

Uniquely, the retort is designed to facilitate the hot pressing aspect of the process while maintaining its seal.

The equipment's pressing mechanism is able to apply significant force to the internal workpieces through the structure of the retort.

This allows for the consolidation of powder materials into high-density components under high heat without breaking the protective atmosphere.

Operational Constraints and Considerations

Thermal Limits of Steel

While constructed from heat-resistant steel, the retort has definitive thermal limitations compared to the heating elements themselves.

Operating near or above the steel's maximum service temperature can cause the retort to lose structural integrity or deform.

Mechanical Stress and Creep

The retort must endure a challenging combination of high temperatures and mechanical pressure simultaneously.

Over extended periods of use, this can lead to "creep" (gradual deformation under stress), meaning the retort's condition must be monitored to ensure the seal remains intact.

Maximizing Sintering Quality

To ensure your equipment produces consistent, high-quality results, consider the specific requirements of your materials in relation to the retort's capabilities.

- If your primary focus is Material Purity: Prioritize the integrity of the retort's seal to prevent any leakage of the protective gas or vacuum loss during the cycle.

- If your primary focus is High Density: Ensure the pressing mechanism is calibrated to apply force effectively through the retort without exceeding the vessel's structural limits.

The retort is the guardian of your process environment; maintaining its integrity is the single most important factor in achieving contamination-free sintering results.

Summary Table:

| Key Function | Description | Primary Benefit |

|---|---|---|

| Environmental Isolation | Physically separates workpieces from heating elements | Prevents material contamination from heaters |

| Atmosphere Control | Creates an independent sealed vessel for vacuum/gas | Prevents oxidation and ensures chemical purity |

| Force Transmission | Allows mechanical pressure application through the retort | Enables high-density consolidation of powders |

| Thermal Protection | Acts as the primary thermal barrier for the reaction zone | Maintains a stable, controlled sintering environment |

Elevate Your Sintering Precision with KINTEK

Achieve unparalleled material purity and structural integrity in your hot pressing processes. Backed by expert R&D and industry-leading manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your laboratory's specific requirements.

Whether you need standard configurations or a fully customizable high-temperature furnace, our team is ready to support your unique research and production goals.

Contact Our Experts Today to discover how KINTEK's advanced thermal solutions can optimize your sintering workflow!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the specific purpose of a Boron Nitride (BN) furnace lid? Protecting Molten Steel Purity

- What functions does a high-density graphite crucible perform? More Than a Container for Copper Refining

- What roles do high-purity graphite molds play in the SPS of copper sulfide? Enhance Your Thermoelectric Material Quality

- What factors should be considered when selecting a laboratory furnace? Ensure Optimal Performance and Safety

- What factors should be considered when selecting an alumina ceramic furnace tube? Ensure Safety and Performance in High-Temp Processes

- Why is a silica crucible selected as the reaction vessel? Ensure Stability and Purity in High-Temp Synthesis

- Why is ultrasonic cleaning with acetone required before thermal oxidation? Ensure Perfect Stainless Steel Adhesion

- What additional convenience feature is included with the water circulating vacuum pump? Discover Easy Mobility and More