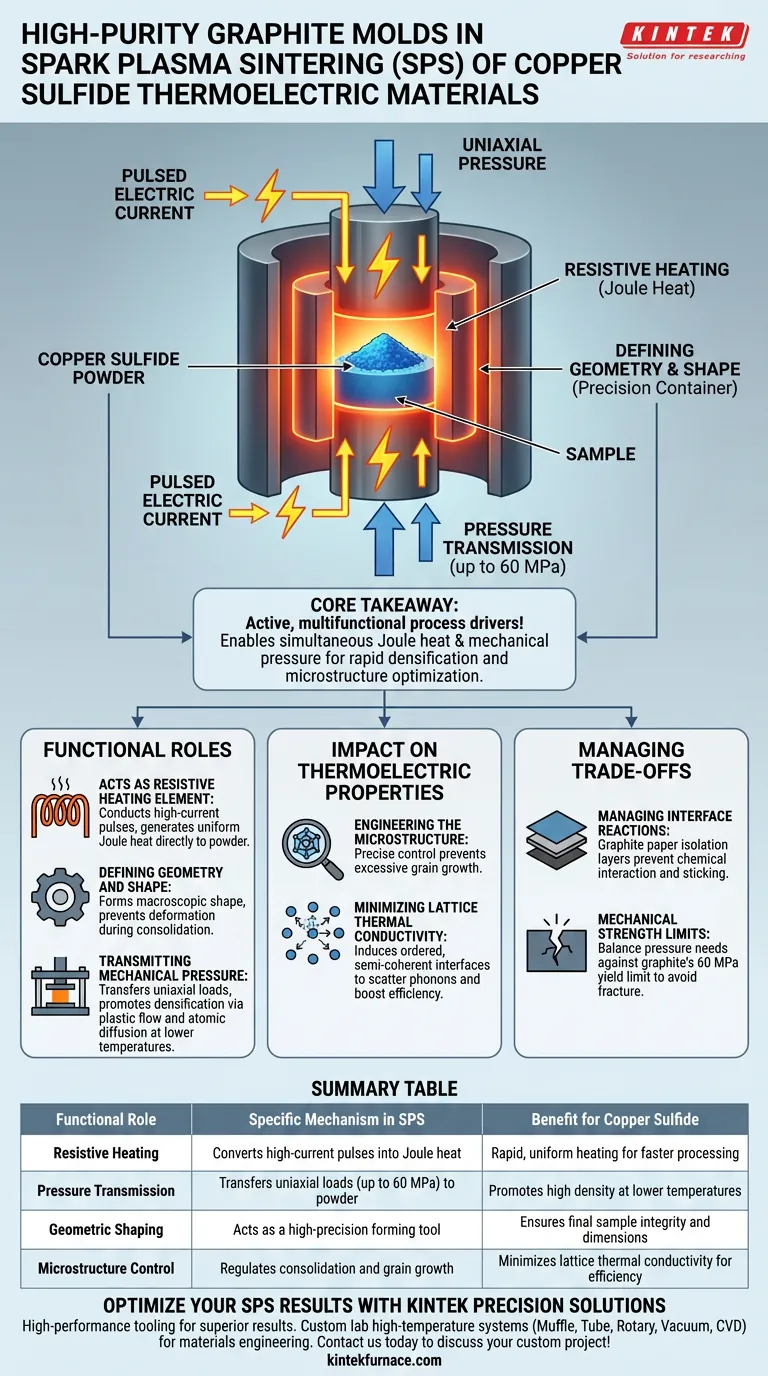

High-purity graphite molds act as active, multifunctional process drivers in Spark Plasma Sintering (SPS), serving simultaneously as the precise shaping container, the primary resistive heating element, and the transmission mechanism for mechanical force. For copper sulfide thermoelectric materials, these molds are critical for converting pulsed electric current into thermal energy while applying the pressure needed to achieve high density at lower temperatures.

Core Takeaway: The graphite mold is not merely a vessel; it is a core component of the energy delivery system. By enabling the simultaneous application of Joule heat and mechanical pressure, the mold facilitates rapid densification and the formation of specific microstructures essential for optimizing thermoelectric efficiency.

The Functional Roles of the Mold

Acting as a Resistive Heating Element

In the SPS process, the mold functions as a conductive medium for high-current pulses (often thousands of amperes).

Because high-purity graphite has specific electrical resistance, passing this current through the mold generates significant Joule heat.

This allows thermal energy to be applied directly to the copper sulfide powder, ensuring rapid and uniform heating compared to external heating methods.

Defining Geometry and Shape

At the most fundamental level, the mold serves as the forming tool that dictates the macroscopic physical shape of the final sample.

It creates a defined volume that contains the powder, preventing deformation as the material transitions from a loose aggregate to a solid mass.

Transmitting Mechanical Pressure

The mold acts as a pressure transmission medium, accurately transferring external loads (uniaxial pressure) to the powder particles.

This pressure promotes densification through mechanisms like plastic flow and atomic diffusion.

By facilitating these mechanisms, the mold allows the copper sulfide to achieve high density at significantly lower temperatures than conventional sintering would require.

Impact on Thermoelectric Properties

Engineering the Microstructure

The precise control of heat and pressure provided by the graphite mold directly influences the microstructure of the copper sulfide.

The rapid consolidation prevents excessive grain growth, which is critical for maintaining the material's performance characteristics.

Minimizing Lattice Thermal Conductivity

The SPS process, enabled by the graphite mold, induces the formation of ordered interfaces with semi-coherent characteristics.

These specific structural features are essential for scattering phonons, which helps minimize lattice thermal conductivity.

Low thermal conductivity is a primary goal in thermoelectric design, directly boosting the material's figure of merit (efficiency).

Understanding the Trade-offs

Managing Interface Reactions

While graphite is excellent for conductivity, it can chemically interact with certain powders or result in adhesion at high temperatures.

To mitigate this, graphite paper (often acting as an isolation layer) is typically placed between the mold and the powder.

This ensures uniform current distribution while preventing the copper sulfide from sticking to the mold, preserving the surface quality of the sample.

Mechanical Strength Limits

Graphite molds have excellent high-temperature strength, but they are not infinitely durable.

They typically withstand pressures up to 60 MPa; exceeding this can lead to mold fracture or deformation.

Operators must balance the need for high pressure to drive densification against the mechanical yield limits of the graphite grade being used.

Making the Right Choice for Your Goal

To maximize the quality of your copper sulfide thermoelectric material, consider how you utilize the mold based on your specific objectives:

- If your primary focus is rapid densification: Prioritize high-strength graphite grades that allow you to maximize the applied pressure (near the 60 MPa limit) to accelerate plastic flow.

- If your primary focus is microstructure precision: Focus on the mold's electrical uniformity and the use of isolation layers (graphite paper) to ensure even Joule heating and prevent surface contamination.

Success in SPS relies on treating the graphite mold as an active participant in the energy transfer process, not just a passive container.

Summary Table:

| Functional Role | Specific Mechanism in SPS | Benefit for Copper Sulfide |

|---|---|---|

| Resistive Heating | Converts high-current pulses into Joule heat | Rapid, uniform heating for faster processing |

| Pressure Transmission | Transfers uniaxial loads (up to 60 MPa) to powder | Promotes high density at lower temperatures |

| Geometric Shaping | Acts as a high-precision forming tool | Ensures final sample integrity and dimensions |

| Microstructure Control | Regulates consolidation and grain growth | Minimizes lattice thermal conductivity for efficiency |

Optimize Your SPS Results with KINTEK Precision Solutions

High-performance materials require high-performance tooling. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temperature systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to your unique sintering needs. Whether you are engineering copper sulfide thermoelectrics or advanced ceramics, our equipment ensures the precise control of heat and pressure necessary for superior results.

Ready to elevate your material synthesis? Contact us today to discuss your custom project!

Visual Guide

References

- Yixin Zhang, Zhen‐Hua Ge. Synergistically optimized electron and phonon transport in high-performance copper sulfides thermoelectric materials via one-pot modulation. DOI: 10.1038/s41467-024-47148-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is rhenium selected as a material for sample capsules? Key Benefits for High-Temperature Experimental Success

- What is the significance of quartz vacuum sealing technology in Dy4T1-xGa12 production? Ensure High-Purity Synthesis

- How does a precise substrate heating system influence fluoride thin film quality? Mastering Structural Integrity

- Why is a precision constant temperature drying oven required for BZT ceramic powders? Ensure Perfect Powder Quality

- What should be evaluated when assessing supplier reliability for alumina ceramic furnace tubes? Ensure Consistent Performance and Support

- What processes can a circulating water vacuum pump provide negative pressure conditions for? Essential Lab Techniques Explained

- Why is a high-precision electronic balance critical in the formulation of geopolymer binders? Precision for Success

- How does a vacuum sealing device protect the experimental environment? Ensure Purity in High-Temp Compression Tests