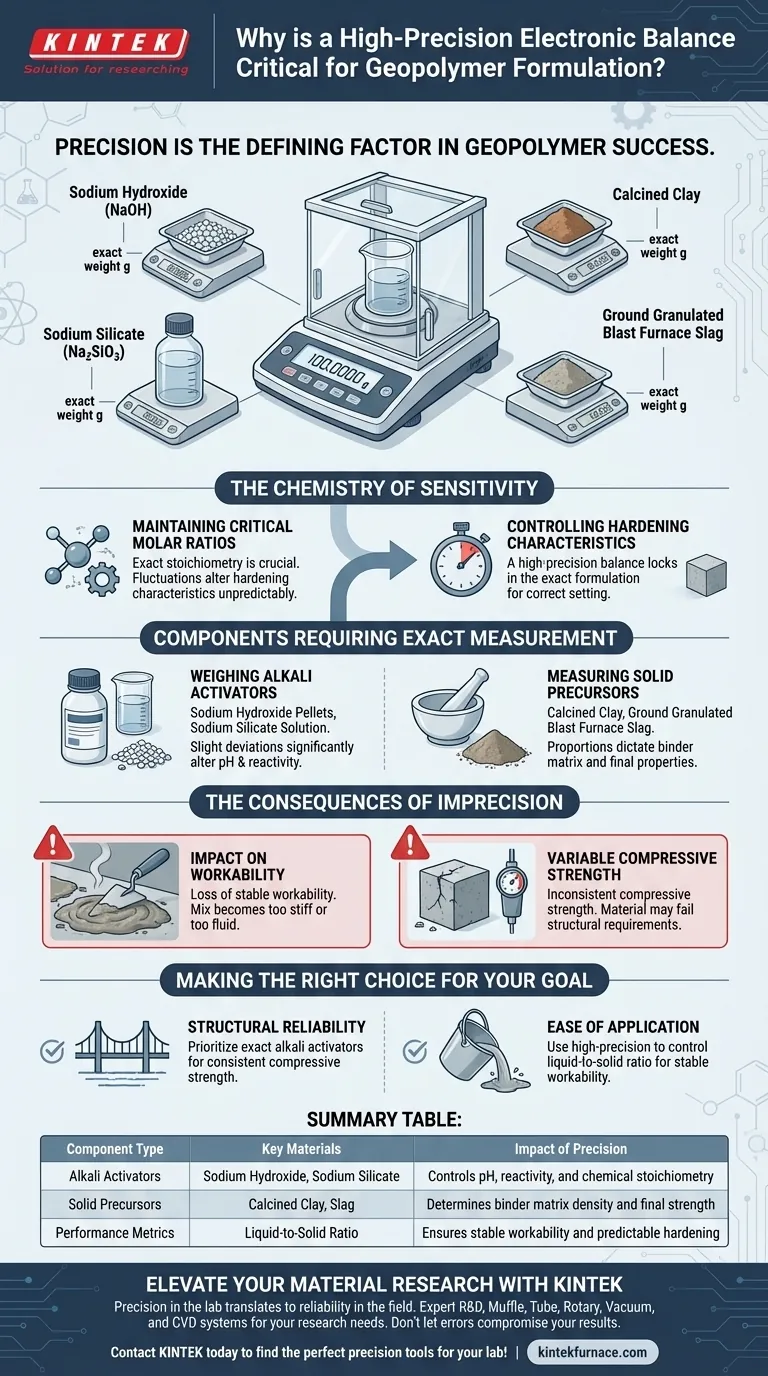

Precision is the defining factor in geopolymer success. A high-precision electronic balance is critical for the formulation of geopolymer binders because it allows for the exact weighing of specific components like sodium hydroxide, sodium silicate, calcined clay, and slag. Without this accuracy, the mixture cannot achieve the specific chemical balance required for proper hardening and structural integrity.

The hardening process of geopolymers is extremely sensitive to the molar ratios of alkali activators. Precise measurement is the only way to ensure stable workability and consistent compressive strength in the final material.

The Chemistry of Sensitivity

Maintaining Critical Molar Ratios

Geopolymerization is not a forgiving process; it relies heavily on exact chemical stoichiometry. The reaction requires specific molar ratios of alkali activators to initiate and sustain the hardening process effectively.

Controlling Hardening Characteristics

If these ratios fluctuate due to measurement errors, the hardening characteristics of the binder change unpredictably. A high-precision balance allows you to lock in the exact formulation required for the material to set correctly.

Components Requiring Exact Measurement

Weighing Alkali Activators

The primary reference highlights the need to accurately weigh sodium hydroxide pellets and sodium silicate solution. These are potent chemicals where even slight deviations in mass can significantly alter the pH and reactivity of the solution.

Measuring Solid Precursors

You must also apply strict accuracy to the solid components, specifically calcined clay and ground granulated blast furnace slag. These materials interact with the activators to form the binder matrix, and their proportions directly dictate the final properties of the geopolymer.

The Consequences of Imprecision

Impact on Workability

One of the most immediate trade-offs of using low-precision equipment is the loss of stable workability. An imbalance in the liquid-to-solid ratio or activator concentration can make the mix too stiff to cast or too fluid to hold its shape.

Variable Compressive Strength

The ultimate trade-off involves the safety and reliability of the structure. Inaccurate weighing leads to inconsistent compressive strength, resulting in a material that may fail to meet structural requirements or degrade prematurely.

Making the Right Choice for Your Goal

To ensure your geopolymer formulation is successful, apply this precision to your specific objectives:

- If your primary focus is structural reliability: Prioritize the exact weighing of alkali activators to maintain the molar ratios that guarantee consistent compressive strength.

- If your primary focus is ease of application: Use high-precision measurement to control the solid-to-liquid ratio, ensuring the mixture retains stable workability during pouring.

Treat your electronic balance not as a simple tool, but as the gatekeeper of your material's chemical integrity.

Summary Table:

| Component Type | Key Materials | Impact of Precision |

|---|---|---|

| Alkali Activators | Sodium Hydroxide, Sodium Silicate | Controls pH, reactivity, and chemical stoichiometry |

| Solid Precursors | Calcined Clay, Slag | Determines binder matrix density and final strength |

| Performance Metrics | Liquid-to-Solid Ratio | Ensures stable workability and predictable hardening |

Elevate Your Material Research with KINTEK

Precision in the lab translates to reliability in the field. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-precision balances and thermal processing equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique geopolymer research needs. Don't let measurement errors compromise your compressive strength or workability.

Contact KINTEK today to find the perfect precision tools for your lab!

Visual Guide

People Also Ask

- What is the role of an optical pyrometer in diffusion bonding? Ensure Precision in High-Temperature Simulations

- What is the primary function of the alumina crucible set in the synthesis of Eu5.08-xSrxAl3Sb6? Expert Analysis

- How does an Aluminum Oxide Crucible ensure MXene purity? Key Role of LSS Etching Protection

- Why is a quartz tube utilized as the primary reaction vessel? Optimize Microwave-Assisted Metal Recovery Efficiency

- What maintenance is required for a water circulating vacuum pump? Ensure Peak Performance and Longevity

- What roles do high-purity graphite molds perform in A357 sintering? Enhancing Aluminum Matrix Composite Performance

- Why are high-purity alumina crucibles used for phosphor synthesis? Ensure Maximum Luminescence and Spectral Purity

- Why must alloy samples be sealed in vacuum-evacuated fused silica containers during diffusion annealing processes?