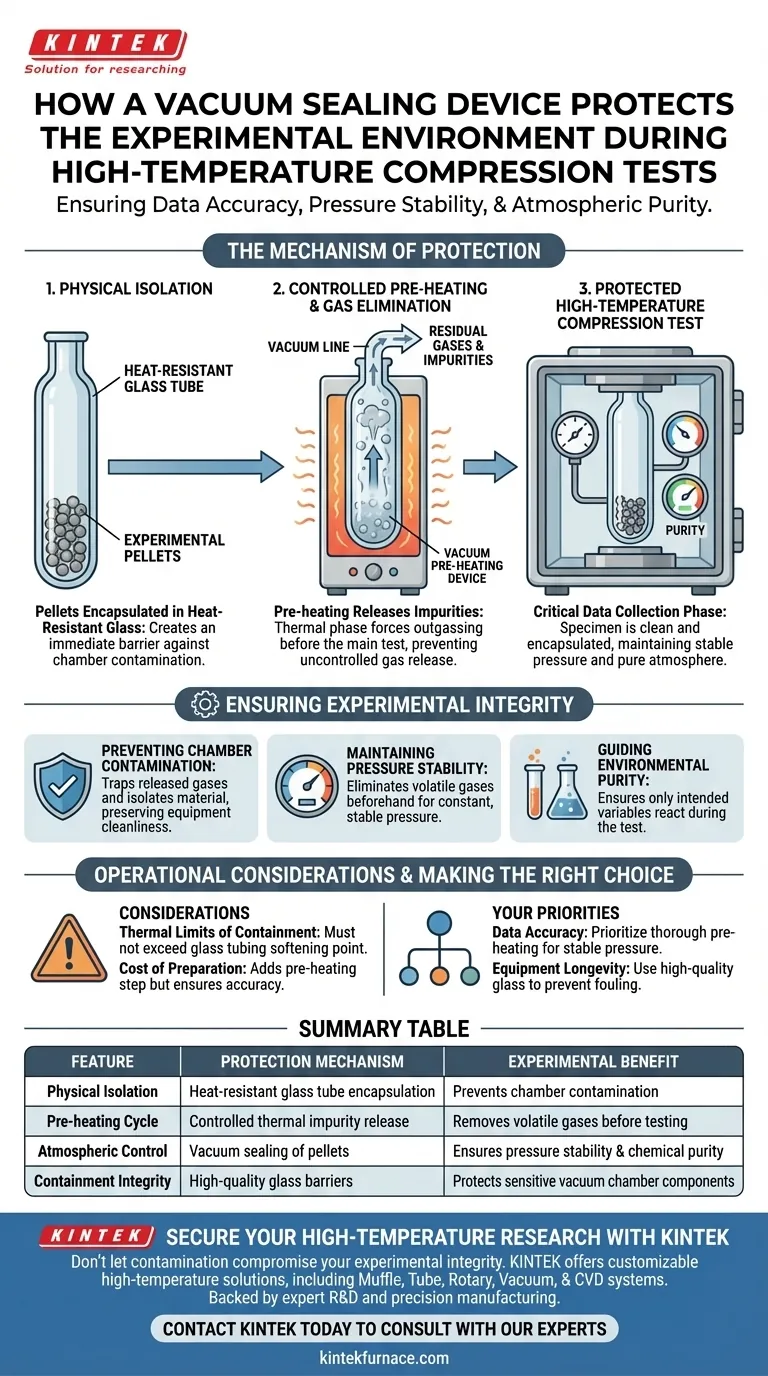

A vacuum sealing device protects the experimental environment by physically isolating specimens within heat-resistant glass tubes and subjecting them to a critical pre-heating treatment. This preparation ensures that any volatile elements are managed before the actual high-temperature compression test begins.

Core Takeaway: By proactively eliminating residual gases and encapsulating the specimen, vacuum sealing prevents vacuum chamber contamination. This safeguards the pressure stability and atmospheric purity necessary for valid high-temperature experimental data.

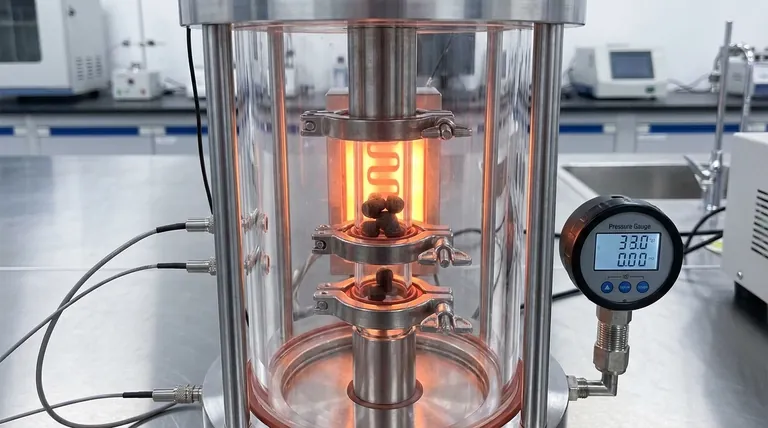

The Mechanism of Protection

Physical Isolation

The device secures the experimental pellets inside heat-resistant glass tubes. This creates an immediate physical barrier between the raw specimen material and the sensitive internal components of the vacuum chamber.

Controlled Pre-heating

Before the high-temperature compression occurs, the device performs a pre-heating treatment. This thermal phase is designed to activate and release impurities while the specimen is still safely contained.

Elimination of Residual Gases

The primary threat to a high-temperature vacuum environment is outgassing. The sealing and pre-heating process effectively forces the pellets to release residual gases prior to the main experiment. This prevents an uncontrolled release of gas during the critical data-collection phase.

Ensuring Experimental Integrity

Preventing Chamber Contamination

By trapping released gases and isolating the material, the device avoids contamination of the vacuum chamber. This preserves the cleanliness of the equipment for current and future tests.

Maintaining Pressure Stability

High-temperature environments are sensitive to pressure fluctuations. By removing volatile gases beforehand, the device ensures pressure stability remains constant throughout the compression test.

Guiding Environmental Purity

The ultimate goal of this protection is to maintain a pure experimental atmosphere. Sealing ensures that the only variables reacting during the compression test are the ones you intend to measure.

Operational Considerations

Thermal Limits of Containment

The protection relies heavily on the integrity of the heat-resistant glass. Operators must ensure the test temperatures do not exceed the softening point of the glass tubing, or the seal—and the protection—will fail.

The Cost of Preparation

Implementing this protection adds a pre-heating step to the workflow. While this increases the time required per sample, it is a non-negotiable trade-off for data accuracy in high-precision environments.

Making the Right Choice for Your Goal

To maximize the reliability of your high-temperature compression tests, consider the following priorities:

- If your primary focus is data accuracy: Prioritize a thorough pre-heating cycle to ensure all residual gases are eliminated before compression begins, guaranteeing stable pressure.

- If your primary focus is equipment longevity: Use high-quality heat-resistant glass tubes to prevent specimen material from permanently fouling the interior of your vacuum chamber.

Effective vacuum sealing is the fundamental step that transforms a volatile experiment into a controlled, measurable scientific process.

Summary Table:

| Feature | Protection Mechanism | Experimental Benefit |

|---|---|---|

| Physical Isolation | Heat-resistant glass tube encapsulation | Prevents chamber contamination from specimens |

| Pre-heating Cycle | Controlled thermal impurity release | Removes volatile gases before critical testing |

| Atmospheric Control | Vacuum sealing of pellets | Ensures pressure stability and chemical purity |

| Containment Integrity | High-quality glass barriers | Protects sensitive vacuum chamber components |

Secure Your High-Temperature Research with KINTEK

Don't let contamination compromise your experimental integrity. KINTEK offers a full suite of customizable high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding lab environments. Backed by expert R&D and precision manufacturing, we provide the tools you need for stable, reproducible, and pure results.

Ready to optimize your lab’s efficiency and data accuracy? Contact KINTEK Today to Consult with Our Experts

Visual Guide

Related Products

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- How are quartz tubes used in laboratory applications? Essential for High-Temp, High-Purity Processes

- What multiple roles do high-purity, high-strength graphite molds play in the Spark Plasma Sintering (SPS) process?

- What are the main types of laboratory furnaces? Find Your Perfect High-Temperature Solution

- Why is a vacuum pump system integrated into a plastic pyrolysis setup? Optimize Yield and Energy Efficiency

- What is the temperature resistance of alumina ceramic tubes? Up to 1800°C for Demanding Applications

- Why is a laboratory-grade high-pressure reactor essential for TiO2 nanoparticles? Optimize Purity and Efficiency

- How is quartz wool utilized in the assembly of reaction tubes? Optimize Crystal Growth and Flux Separation

- What is the importance of the quartz boat in BPEA crystal growth? Essential for Purity and Performance