Precise substrate heating is the primary driver of structural integrity in fluoride thin film deposition. By supplying controlled thermal energy, the system regulates surface mobility, allowing fluoride molecules to nucleate effectively and transition from scattered island growth to a cohesive, continuous film.

The core function of substrate heating is to enable molecules to arrange themselves efficiently before they lock into place. This prevents the formation of internal voids and structural errors, resulting in a denser, smoother, and defect-free material.

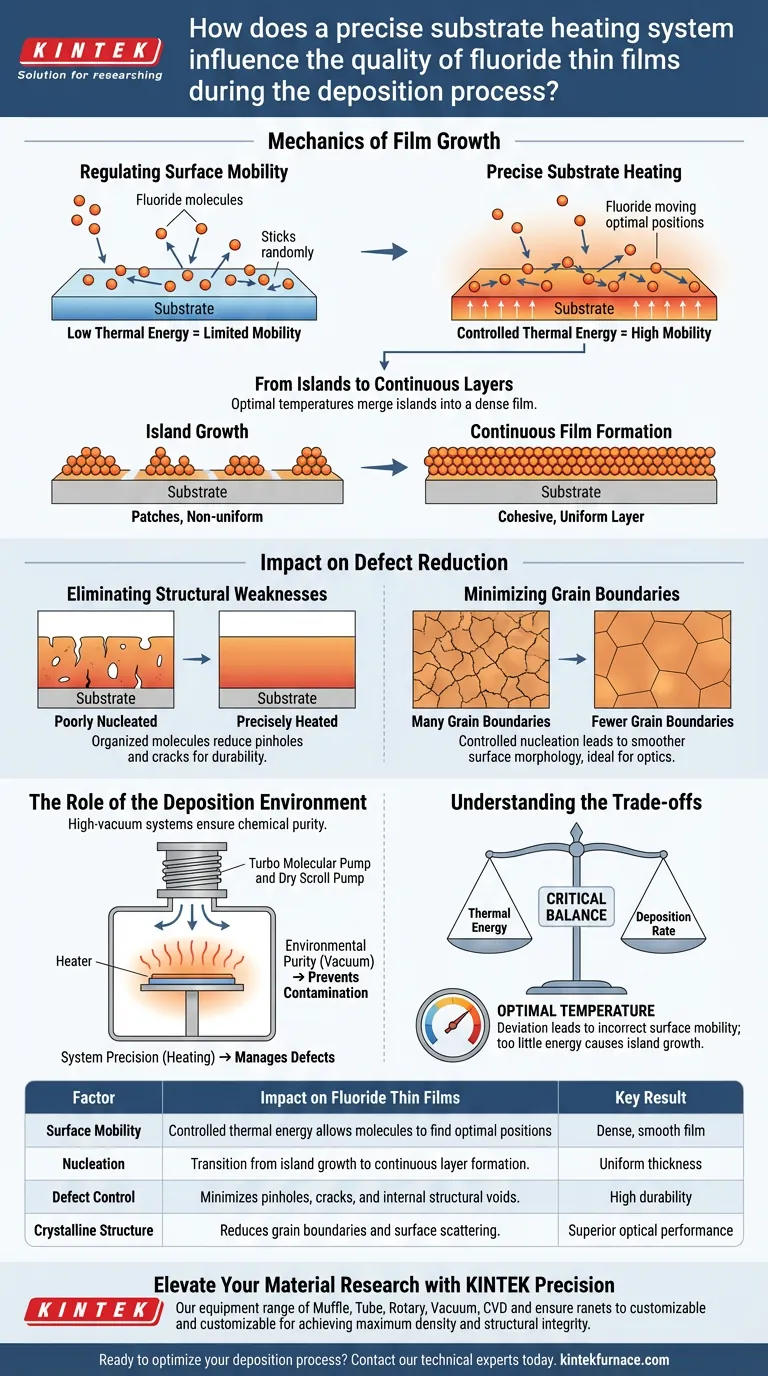

The Mechanics of Film Growth

Regulating Surface Mobility

The quality of a thin film depends heavily on how molecules behave once they land on the substrate. A precise heating system provides the specific thermal energy required to mobilize these molecules.

This added energy allows the fluoride molecules to move across the surface rather than sticking immediately where they land. This movement is essential for the molecules to find energetically favorable positions.

From Islands to Continuous Layers

Without adequate heat, deposition often results in "island growth," where isolated clusters of material form without connecting.

Optimal substrate temperatures promote a phase transition where these islands merge. This leads to continuous film formation, ensuring the layer is uniform rather than patchy.

Impact on Defect Reduction

Eliminating Structural Weaknesses

A major benefit of precise heating is the reduction of internal defects. When molecules are allowed to organize properly, the likelihood of pinholes and cracks diminishes significantly.

This structural continuity is vital for the film's durability and performance. It prevents the mechanical failures often associated with poorly nucleated films.

Minimizing Grain Boundaries

The heating process also influences the crystalline structure of the fluoride. By controlling nucleation, the system reduces the number of grain boundaries.

Fewer grain boundaries result in a smoother surface morphology. This is particularly important for optical applications where surface scattering must be minimized.

The Role of the Deposition Environment

System Precision vs. Environmental Purity

While the heating system controls the physical structure and arrangement of the film, it operates within a larger ecosystem.

High-vacuum systems (utilizing turbo molecular and dry scroll pumps) run in parallel to ensure the chemical purity of the film. While heat manages the defects, the vacuum prevents contamination from impurity gases during the process.

Understanding the Trade-offs

The Necessity of "Optimal" Temperature

The reference emphasizes "optimal" substrate temperatures, implying that precision is not just about applying heat, but applying the exact amount of heat.

If the temperature deviates from this optimum, the surface mobility will be incorrect. Too little energy leads to the island growth mentioned earlier, resulting in porous, defect-ridden films.

Balancing Variables

There is a critical balance between thermal energy and deposition rate.

Precise heating allows you to dictate the film's density, but it must be synchronized with other system parameters to ensure the molecules have time to settle without being buried by incoming material.

Making the Right Choice for Your Goal

To achieve the best results with fluoride thin films, you must distinguish between structural needs and purity needs.

- If your primary focus is Structural Integrity: Prioritize the precision of your substrate heating system to ensure high surface mobility and a crack-free, continuous film.

- If your primary focus is Chemical Purity: Ensure your system utilizes a high-vacuum setup with turbo molecular pumps to eliminate gas contamination during transport.

The most durable and high-performing films are achieved when precise thermal control drives molecular organization within an ultra-clean vacuum environment.

Summary Table:

| Factor | Impact on Fluoride Thin Films | Key Result |

|---|---|---|

| Surface Mobility | Controlled thermal energy allows molecules to find optimal positions. | Dense, smooth film |

| Nucleation | Transition from island growth to continuous layer formation. | Uniform thickness |

| Defect Control | Minimizes pinholes, cracks, and internal structural voids. | High durability |

| Crystalline Structure | Reduces grain boundaries and surface scattering. | Superior optical performance |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect fluoride thin film requires a delicate balance of thermal energy and vacuum purity. KINTEK provides the cutting-edge laboratory equipment necessary to master these variables.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique thin-film deposition and high-temperature processing needs. Our precise heating solutions ensure your materials achieve maximum density and structural integrity every time.

Ready to optimize your deposition process? Contact our technical experts today to find the perfect system for your lab.

Visual Guide

References

- Thin Fluoride Insulators for Improved 2D Transistors: From Deposition Methods to Recent Applications. DOI: 10.1002/pssr.202500200

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- Why are Type K thermocouples preferred in industrial furnaces? Unlock Reliable Precision for High-Heat Control

- Why is a copper getter chamber integrated into heating systems? Ensure Ultra-Pure Alloy Processing

- What is the function of a high-precision constant temperature oven in LIG composite curing? Achieve Perfect Stability

- How does a high-precision heating stage contribute to the drying and crystallization of FAPbBr3 nanosheets?

- What is the necessity of configuring non-contact infrared pyrometers for temperature monitoring? Ensure Sintering Precision

- What role does a high-purity graphite mold play during the SPS sintering process of Al2O3-TiC? Unlock Process Efficiency

- What is the role of a BN crucible in Ca0.5Sr0.5AlSiN3:Eu2+ synthesis? Achieve High-Purity Nitride Phosphors

- What is the purpose of using a corundum crucible and graphite powder? Optimize Your High-Entropy Alloy Annealing