Selecting the right laboratory furnace is a critical decision that hinges on a systematic evaluation of your application's technical requirements, operational environment, and safety protocols. The most important factors to consider are the required temperature range and uniformity, the necessity for atmospheric control, and the physical size and geometry of the furnace chamber or tube.

The goal is not to buy the furnace with the highest temperature or most features, but to precisely match the equipment's capabilities—temperature uniformity, atmospheric control, and chamber geometry—to your specific material and process requirements.

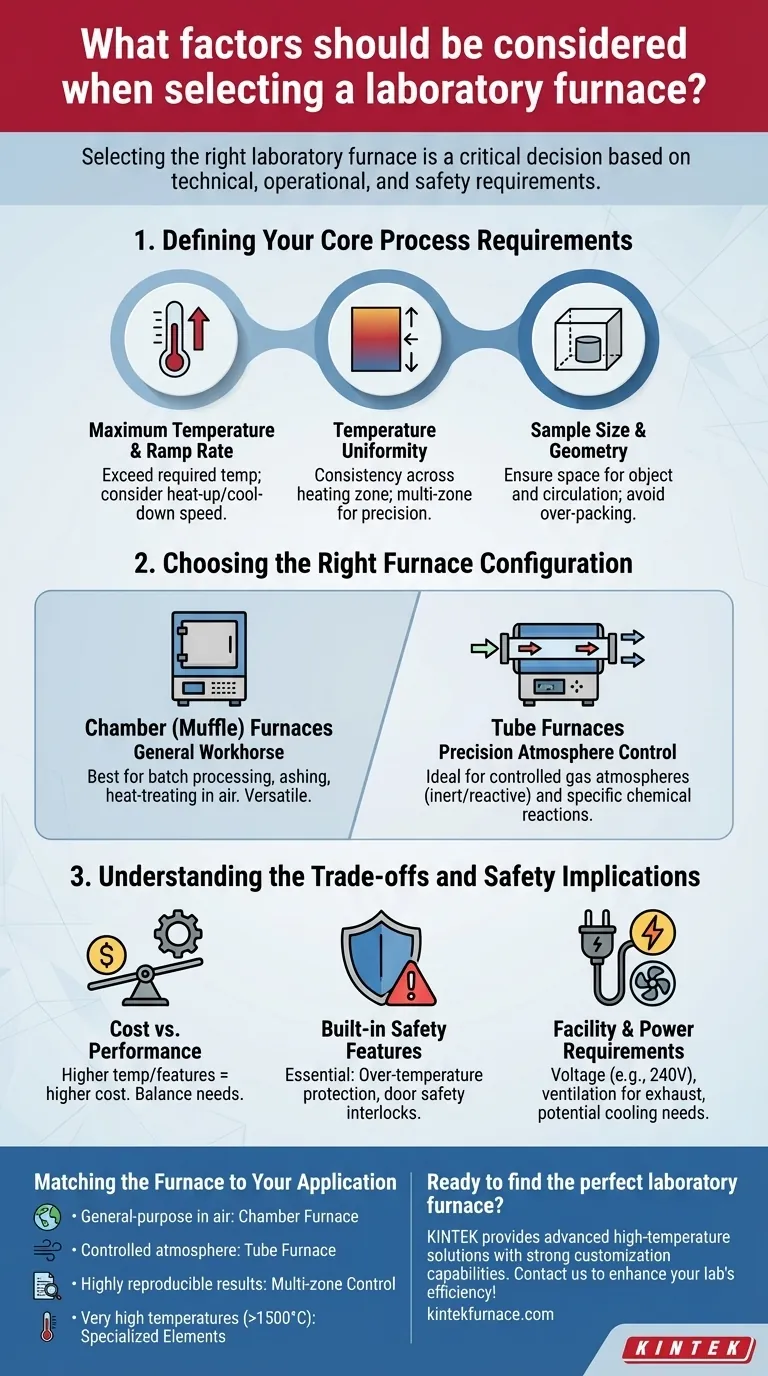

1. Defining Your Core Process Requirements

Before evaluating specific models, you must first define the non-negotiable parameters of your thermal process. Answering these questions first will narrow your search significantly.

Maximum Temperature and Ramp Rate

The maximum operating temperature is the most obvious specification, but it's not the only thermal parameter to consider. You must select a furnace that can comfortably exceed your required process temperature, as constantly running at the absolute maximum will shorten the life of the heating elements.

Equally important is the ramp rate, or how quickly the furnace can heat up and cool down. Some processes require slow, controlled heating, while others, like rapid thermal annealing, demand speed.

Temperature Uniformity

Temperature uniformity describes how consistent the temperature is across the entire heating zone. A furnace might have a setpoint of 1000°C, but some areas inside could be 990°C while others are 1010°C.

For sensitive processes like crystal growth or calibrating sensors, poor uniformity leads to inconsistent results. Furnaces with multiple heating zones, each with its own controller, offer far superior uniformity but at a higher cost.

Sample Size and Geometry

Consider the dimensions of your sample, including any crucible, substrate holder, or container it will be in. You must ensure there is adequate space not only for the object itself but also for proper air or gas circulation around it. Over-packing a furnace chamber will compromise temperature uniformity.

2. Choosing the Right Furnace Configuration

The physical design of the furnace is dictated by your sample shape and atmospheric requirements.

Chamber (Muffle) Furnaces: The General Workhorse

A chamber furnace is essentially a heated box. This is the most common and versatile configuration, ideal for batch processing, ashing, debinding, and heat-treating samples in air. They are well-suited for processing multiple samples at once or for handling larger, irregularly shaped items.

Tube Furnaces: Precision Atmosphere Control

A tube furnace uses heating elements that encircle a ceramic or quartz tube. The sample is placed inside this tube, which can be sealed at the ends.

This design is the standard for any process requiring a controlled atmosphere. By flowing inert gases (like Argon or Nitrogen) or reactive gases through the tube, you can prevent oxidation or introduce specific chemical reactions.

3. Understanding the Trade-offs and Safety Implications

A laboratory furnace is a significant investment with major safety considerations. Objectively weighing the costs against the necessary features is crucial.

Cost vs. Performance

There is a direct correlation between price and performance. Higher maximum temperatures require more exotic (and expensive) heating elements and insulation. Likewise, multi-zone temperature control and gas-handling systems for atmospheric control add significant cost and complexity.

Built-in Safety Features

Modern furnaces should include essential safety interlocks. Over-temperature protection is a non-negotiable feature that uses an independent controller to shut the furnace down if it exceeds a safe limit, protecting your sample, the equipment, and the lab. A door safety switch that cuts power to the heating elements when the door is opened is another critical feature.

Facility and Power Requirements

Do not overlook the installation requirements. Smaller, lower-temperature furnaces may run on a standard wall outlet. However, larger or high-temperature furnaces often require a 240V or three-phase power supply, which may necessitate costly electrical work.

Furthermore, ensure you have adequate ventilation to exhaust heat and any potential process off-gassing. Some high-power units may even require a water supply for cooling.

Matching the Furnace to Your Application

Your choice should be guided by a clear understanding of your primary goal.

- If your primary focus is general-purpose heat treating or ashing in air: A simple, single-zone chamber furnace offers the best value and operational simplicity.

- If your primary focus is annealing or synthesis under a controlled gas atmosphere: A tube furnace with proper sealing flanges and gas handling capabilities is essential.

- If your primary focus is achieving highly reproducible results for sensitive materials: Prioritize a furnace with multi-zone control for superior temperature uniformity.

- If your primary focus is working with very high temperatures (>1500°C): Be prepared for specialized heating elements (e.g., MoSi2), increased power requirements, and higher operational costs.

By systematically aligning these technical factors with your core scientific goal, you ensure your investment yields reliable, reproducible, and safe results.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | Maximum operating temperature and ramp rate for process needs |

| Temperature Uniformity | Consistency across heating zone; multi-zone control for precision |

| Sample Size and Geometry | Chamber dimensions to ensure proper fit and circulation |

| Furnace Configuration | Chamber (Muffle) for general use, Tube for atmosphere control |

| Safety Features | Over-temperature protection, door safety switches |

| Power and Facility | Voltage requirements (e.g., 240V), ventilation, and cooling needs |

Ready to find the perfect laboratory furnace for your needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for reliable and safe results. Contact us today to discuss how we can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development