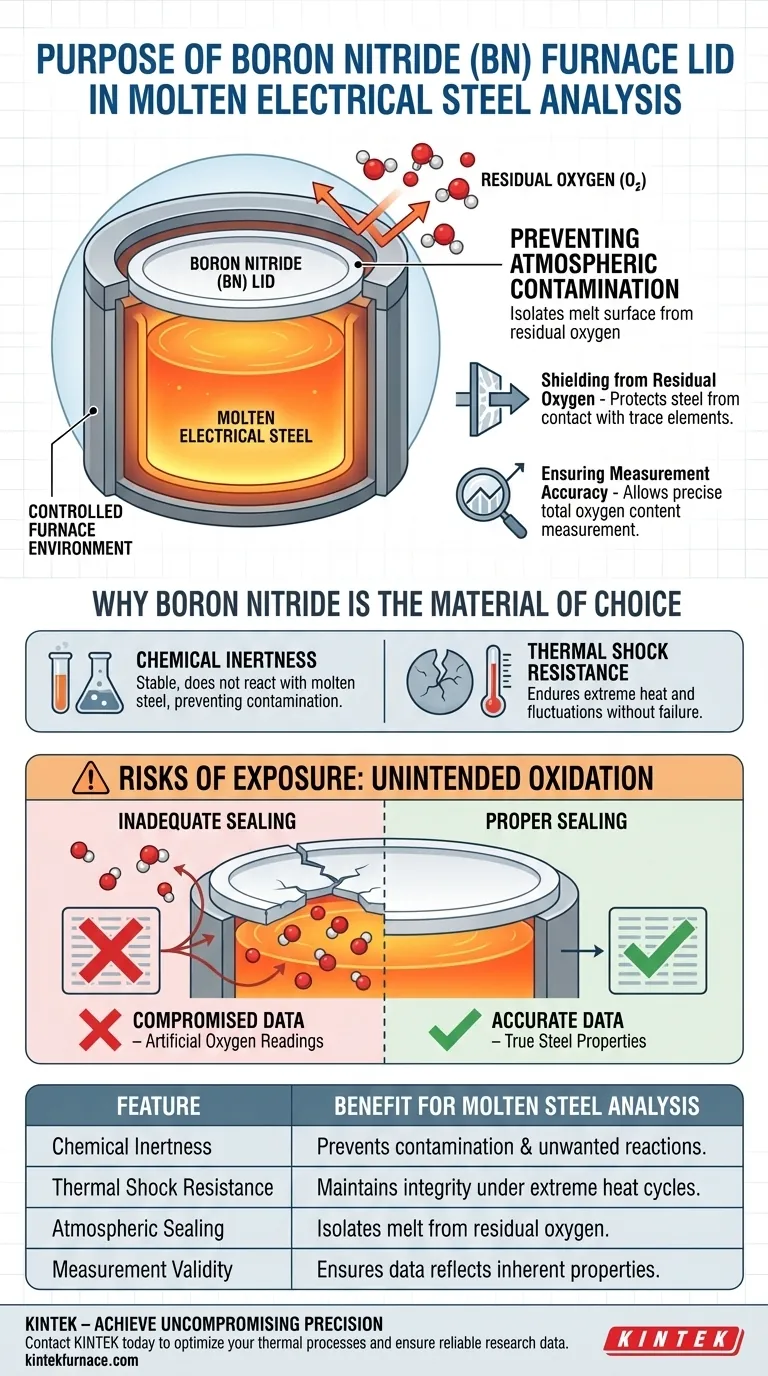

Preventing atmospheric contamination is the specific purpose of a Boron Nitride (BN) furnace lid when analyzing molten electrical steel. Its primary function is to seal and shield the melt surface, effectively isolating it from residual oxygen present within the furnace environment. By preventing this contact, the lid stops unintended oxidation that would otherwise compromise the material's properties and test results.

The BN lid acts as a critical barrier against oxidation, essential for maintaining a controlled atmosphere to guarantee accurate total oxygen content measurements.

The Critical Role of Oxidation Control

Shielding from Residual Oxygen

Even within a furnace designed for high-temperature testing, the atmosphere may contain trace elements that can alter the sample. The BN lid provides a physical shield for the melt surface.

This barrier is necessary to protect the steel from contact with residual oxygen. Without this seal, the separation between the test sample and the furnace atmosphere is compromised.

Ensuring Measurement Accuracy

The presence of the lid is directly tied to the validity of the data collected. Specifically, it allows for the precise measurement of total oxygen content.

If the melt were exposed to the furnace atmosphere, external oxygen would react with the steel. This would artificially inflate oxygen readings, leading to incorrect conclusions about the steel's inherent properties.

Why Boron Nitride is the Material of Choice

Chemical Inertness

A protective lid must not introduce its own contaminants into the molten sample. Boron Nitride is chosen for its chemical inertness.

This property ensures that the lid remains stable and does not react with the molten electrical steel. It effectively contains the environment without becoming part of the chemical equation.

Thermal Shock Resistance

The testing environment for molten steel involves extreme heat and potential temperature fluctuations. The material used for the lid must endure these conditions without physical failure.

Boron Nitride possesses high thermal shock resistance. This ensures the lid maintains its structural integrity and sealing capability throughout the heating process.

Understanding the Risks of Exposure

The Consequence of Inadequate Sealing

The primary "pitfall" in this context is the failure to maintain a perfect seal. If the lid is compromised or not used, the "controlled atmosphere" mentioned in the reference is lost.

This leads to unintended oxidation, which is the exact variable the apparatus is designed to eliminate. The resulting data will reflect the environmental contamination rather than the true quality of the electrical steel.

Making the Right Choice for Your Goal

To ensure the reliability of your molten steel analysis, consider the following:

- If your primary focus is data accuracy: Ensure the BN lid is properly seated to completely isolate the melt from residual oxygen, preventing skew in total oxygen content figures.

- If your primary focus is equipment durability: Rely on the thermal shock resistance of Boron Nitride to maintain a consistent barrier without fracturing during rapid temperature changes.

By utilizing the BN lid, you guarantee that the properties measured are those of the steel itself, not the result of atmospheric interference.

Summary Table:

| Feature | Benefit for Molten Steel Analysis |

|---|---|

| Chemical Inertness | Prevents sample contamination and unwanted chemical reactions. |

| Thermal Shock Resistance | Maintains structural integrity under extreme heating/cooling cycles. |

| Atmospheric Sealing | Isolates melt surface from residual oxygen to prevent oxidation. |

| Measurement Validity | Ensures data reflects inherent steel properties, not environmental pollution. |

Achieve Uncompromising Precision in Your High-Temp Research

Maintaining a pristine environment is critical for accurate material analysis. KINTEK provides the specialized equipment needed to eliminate variables like unintended oxidation. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temperature furnaces designed for your unique specifications.

Whether you are analyzing electrical steel or developing advanced ceramics, our team is ready to help you optimize your thermal processes. Contact KINTEK today to discuss your custom furnace needs and ensure your research data is always reliable.

Visual Guide

References

- Lukas Neubert, Olena Volkova. Effect of Oxygen on Thermophysical Properties of Molten High-Silicon Electrical Steels and Its Impact on Bubble Formation Behavior. DOI: 10.1007/s11663-025-03594-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the primary function of an alumina crucible in preparing B2O3–ZnO–BaO shielding glass? Process Secrets Revealed

- Why are support frames important for the alumina furnace tube? Prevent High-Temperature Deformation and Failure

- What is the function of a high alumina crucible in chloride salt purification? Protect Purity and Thermal Stability

- Why are high-purity zirconia grinding balls preferred over steel? Achieve Ultra-Pure Ceramic Grinding Results

- Why are long alumina boats selected as sample containers for zone refining experiments? Optimize Material Purification

- How do industrial sealing clamps and O-ring systems ensure process repeatability? Achieve Consistent Sintering Quality

- What is the primary function of vacuum quartz tubes in Bi-Sb alloy preparation? Ensure Purity & Precise Stoichiometry

- What is the role of a laboratory oven in the pre-treatment of Date Palm Stones? Enhance Torrefaction & Grinding Efficiency