Long alumina boats are selected primarily for their ability to maintain strict physical controls while resisting chemical degradation. They provide specific protection against chloride corrosion and utilize a high aspect ratio to create the distinct temperature gradients required to physically separate melting and solidification zones.

Zone refining relies on precise thermal management to move impurities. Long alumina boats provide the geometry necessary to match one-dimensional modeling, ensuring effective solute sweeping while maintaining structural integrity against corrosive elements.

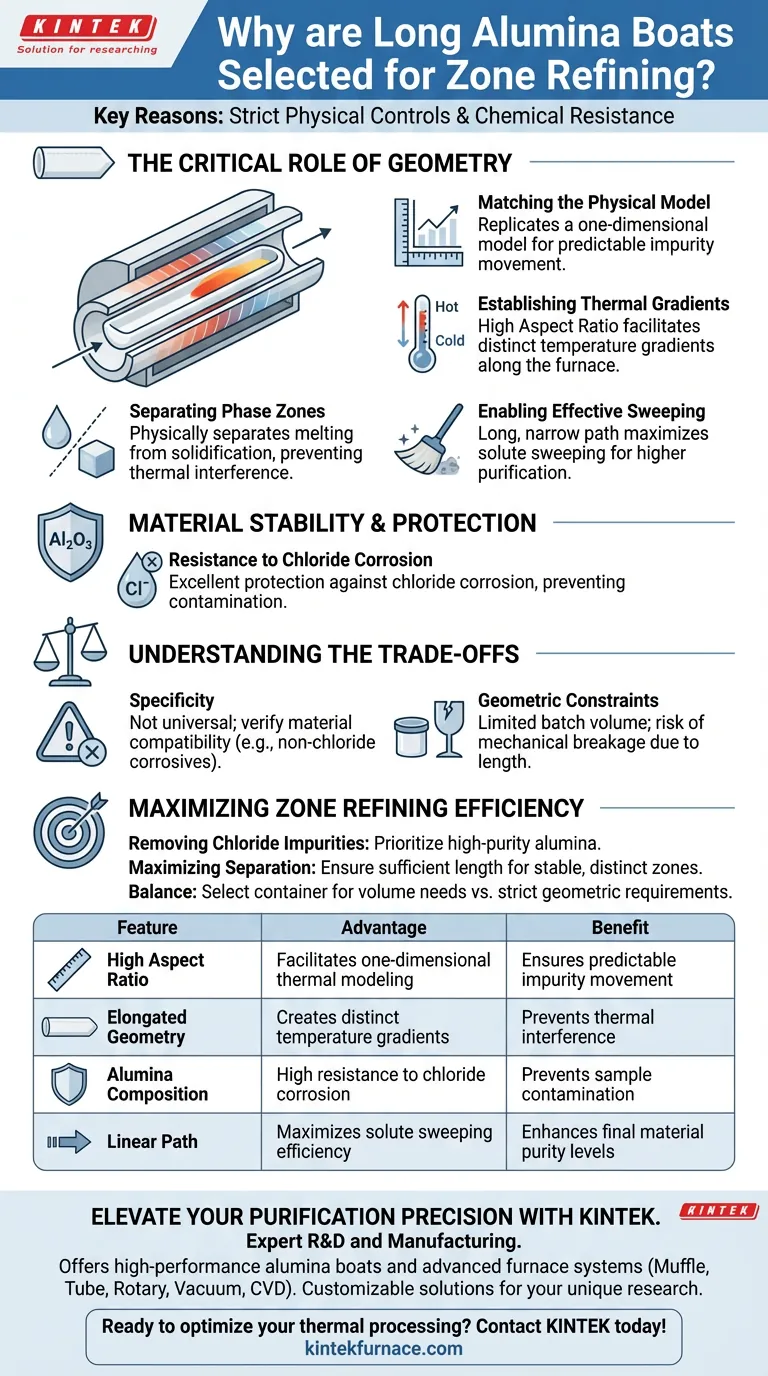

The Critical Role of Geometry

Matching the Physical Model

The success of zone refining often depends on replicating a one-dimensional model in a real-world setting.

Long boats provide the linear physical geometry required to approximate this theoretical model. This alignment ensures that the mathematical predictions of impurity movement match the experimental results.

Establishing Thermal Gradients

A high aspect ratio (length versus width) is the most critical geometric feature of these containers.

This elongated shape facilitates the formation of distinct temperature gradients along the tube furnace. It allows you to maintain a sharp difference in temperature over distance, which is essential for process control.

Separating Phase Zones

For zone refining to work, the melting zone must be physically distinct from the solidification zone.

The length of the alumina boat physically separates these regions. This separation ensures that the molten zone can travel cleanly through the solid material without thermal interference from the opposing phase.

Enabling Effective Sweeping

The ultimate goal of this geometry is the enrichment of solutes.

By forcing the material through a long, narrow path, the process effectively "sweeps" impurities from one end of the sample to the other. The elongated path maximizes the exposure of the material to the moving zone, increasing purification efficiency.

Material Stability and Protection

Resistance to Chloride Corrosion

Material purity is irrelevant if the container itself reacts with the sample.

Alumina boats are specifically chosen for their excellent protection against chloride corrosion. This chemical inertness prevents the container from introducing new contaminants or degrading during the high-heat cycle of the experiment.

Understanding the Trade-offs

Specificity of Corrosion Resistance

While alumina is excellent for chlorides, it is not a universal solution for all corrosive environments.

You must verify that your specific sample does not react with aluminum oxide. Relying on alumina for non-chloride corrosive environments without verification can lead to container failure or sample contamination.

Geometric Constraints

The high aspect ratio that aids purification also creates physical limitations.

Long, narrow boats limit the total volume of material you can process in a single batch compared to wider containers. Furthermore, the extended length increases the risk of mechanical breakage if the boat is handled improperly during loading or unloading.

Maximizing Zone Refining Efficiency

To ensure you are getting the most out of your experimental setup, consider your primary objective:

- If your primary focus is removing chloride-based impurities: Prioritize high-purity alumina boats to prevent container degradation from re-contaminating your sample.

- If your primary focus is maximizing separation efficiency: Ensure your boat is sufficiently long to allow for a stable, distinct molten zone that does not overlap with the solidification front.

Select the container that balances your volume needs with the strict geometric requirements of the thermal gradient.

Summary Table:

| Feature | Advantage in Zone Refining | Benefit to Experiment |

|---|---|---|

| High Aspect Ratio | Facilitates one-dimensional thermal modeling | Ensures predictable impurity movement |

| Elongated Geometry | Creates distinct temperature gradients | Prevents thermal interference between melting and solidification |

| Alumina Composition | High resistance to chloride corrosion | Prevents sample contamination and container degradation |

| Linear Path | Maximizes solute sweeping efficiency | Enhances final material purity levels |

Elevate Your Purification Precision with KINTEK

Achieving ultra-high purity in zone refining requires the perfect balance of geometry and material stability. Backed by expert R&D and manufacturing, KINTEK offers high-performance alumina boats alongside our advanced Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard dimensions or customizable high-temperature lab furnaces tailored for your unique research needs, our team provides the technical excellence required to drive your innovations forward.

Ready to optimize your thermal processing? Contact KINTEK today for a customized solution.

Visual Guide

References

- Alex Scrimshire, Paul A. Bingham. Benchtop Zone Refinement of Simulated Future Spent Nuclear Fuel Pyroprocessing Waste. DOI: 10.3390/ma17081781

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the role of quartz capillaries in the vacuum sealing process of sulfur? Enhance Purity and In-Situ Analysis

- What is the key role of a vacuum filter in a waste magnesium vacuum distillation system? Protecting Your Pumps from Catastrophic Damage

- How has the circulating water vacuum pump been received in practical use? Durable, Cost-Effective for Lab Tasks

- What is the primary purpose of a vacuum pump in photocatalytic CO2 reduction? Ensure Pure Environments for Accurate Data

- What role do high-strength graphite molds play during SnSe consolidation? Essential for High-Performance Densification

- Alumina vs. Platinum Crucibles for Lithium Titanate (LTO) Synthesis: Which is Right for You?

- What voltage options are available for the water circulating vacuum pump? Choose the Right Voltage for Your Lab

- What are the material requirements for a quartz boat in APVT? Ensure High-Purity Sb2Se3 Nanowire Growth