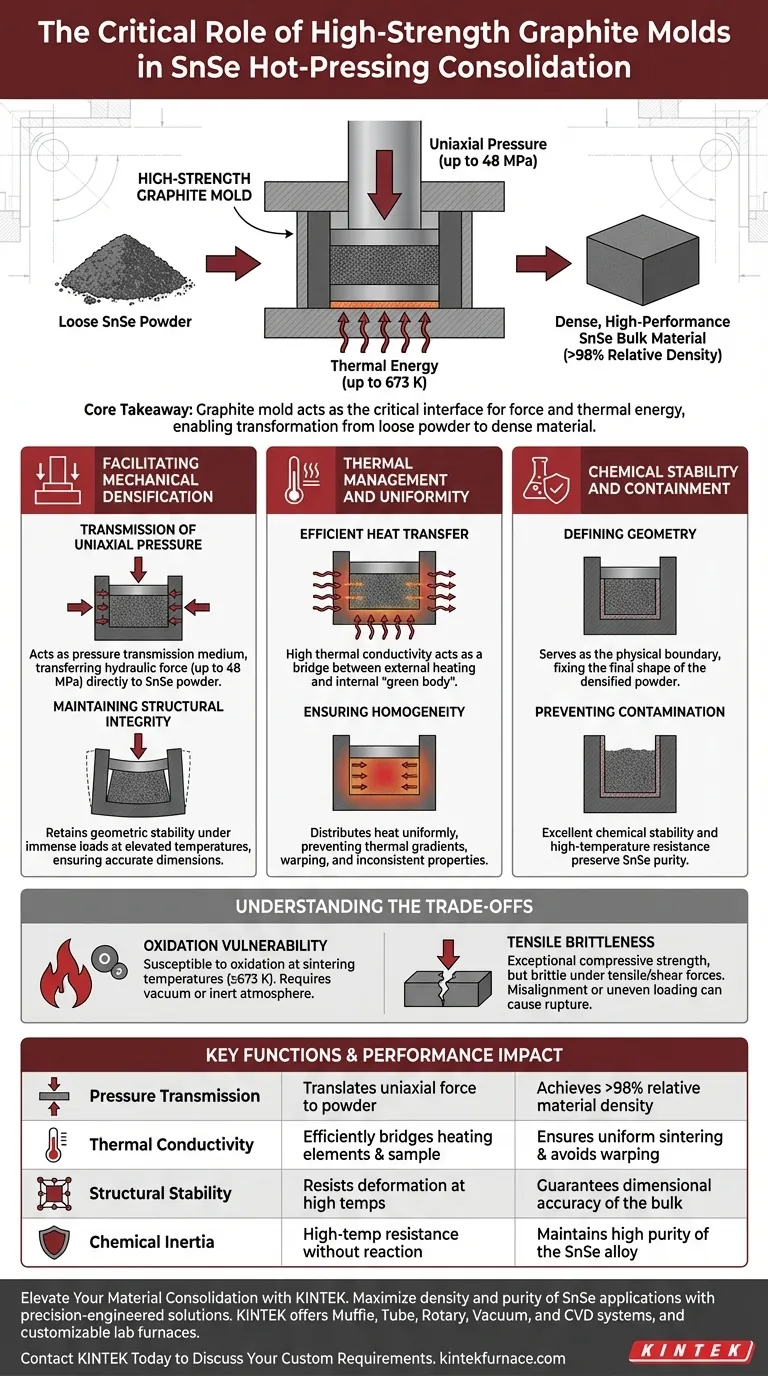

High-strength graphite molds act as the critical interface for both force and thermal energy during the consolidation of tin selenide (SnSe). They serve simultaneously as a shaping container and a transmission medium, withstanding pressures of 48 MPa at temperatures around 673 K to facilitate the transformation of loose powder into a dense, high-performance bulk material.

Core Takeaway The graphite mold is not merely a passive container; it is an active transmission tool that allows for the precise application of uniaxial pressure and uniform heat. This dual capability is essential for achieving the high relative density (exceeding 98 percent) required for high-performance tin selenide applications.

Facilitating Mechanical Densification

To transform tin selenide powder into a solid bulk material, the mold must translate external force into internal density.

Transmission of Uniaxial Pressure

The primary mechanical function of the mold is to act as a pressure transmission medium. The mold receives force from the hot press ram—often hydraulic pressures up to 48 MPa or higher—and transfers this load directly to the SnSe powder.

Maintaining Structural Integrity

While transferring this immense pressure, the mold must resist deformation. High-strength graphite retains its geometric stability even when subjected to significant mechanical loads (e.g., 67.7 MPa) at elevated temperatures, ensuring the final product maintains accurate dimensions.

Thermal Management and Uniformity

The quality of the sintered SnSe depends heavily on how heat is applied during the pressing phase.

Efficient Heat Transfer

Graphite possesses excellent thermal conductivity, which allows it to act as an effective bridge between the external heating elements and the internal composite "green body" (the compressed powder).

Ensuring Homogeneity

The mold ensures that heat is distributed uniformly throughout the sample. This prevents thermal gradients that could lead to uneven sintering, warping, or inconsistent material properties within the final tin selenide block.

Chemical Stability and Containment

Beyond heat and pressure, the environment inside the mold dictates the purity of the final material.

Defining Geometry

The mold serves as the physical boundary that fixes the shape of the powder consolidation. It confines the SnSe powder, forcing it to densify into the specific volume defined by the mold cavity.

Preventing Contamination

High-strength graphite exhibits excellent chemical stability and high-temperature resistance. This ensures the mold does not undergo harmful reactions with the tin selenide powder, preserving the chemical purity of the alloy during densification.

Understanding the Trade-offs

While graphite is the standard for this process, it is important to recognize its operational constraints to ensure process safety and success.

Oxidation Vulnerability

Graphite is highly susceptible to oxidation at the temperatures used for sintering (e.g., 673 K and above). Consequently, the hot-pressing process must occur in a vacuum or an inert gas atmosphere to prevent the mold from degrading.

Tensile Brittleness

Although graphite has exceptional compressive strength (handling the squeezing force), it is brittle regarding tensile or shear forces. Misalignment of the press rams or uneven loading can cause the mold to rupture catastrophically rather than deform plastically.

Making the Right Choice for Your Goal

To maximize the effectiveness of high-strength graphite molds in your specific application, consider the following principles:

- If your primary focus is Maximum Density: Prioritize a mold design with thick walls to withstand the upper limits of uniaxial pressure (50+ MPa) without radial expansion.

- If your primary focus is Material Purity: Ensure the use of high-purity graphite grades and a strictly controlled vacuum environment to prevent carbon contamination or oxidation.

- If your primary focus is Dimensional Accuracy: Utilize segmented pressurization processes, as the mold's rigidity allows for precise pressure-holding phases that lock in final dimensions.

By leveraging the high thermal conductivity and compressive strength of graphite, you ensure the successful consolidation of tin selenide into a dense, high-integrity material.

Summary Table:

| Function | Description | Key Performance Impact |

|---|---|---|

| Pressure Transmission | Translates uniaxial force (up to 48 MPa) to powder | Achieves >98% relative material density |

| Thermal Conductivity | Efficiently bridges heating elements and sample | Ensures uniform sintering and avoids warping |

| Structural Stability | Resists deformation at high temps (up to 673 K) | Guarantees dimensional accuracy of the bulk |

| Chemical Inertia | High-temperature resistance without reaction | Maintains high purity of the SnSe alloy |

Elevate Your Material Consolidation with KINTEK

Maximize the density and purity of your SnSe applications with precision-engineered solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable lab high-temp furnaces tailored to your unique research needs.

Whether you require superior thermal management or robust pressure-resistant environments, our team is ready to provide the high-performance tools your lab deserves.

Contact KINTEK Today to Discuss Your Custom Requirements

Visual Guide

References

- Andrew Golabek, Holger Kleinke. Large Improvements in the Thermoelectric Properties of SnSe by Fast Cooling. DOI: 10.3390/ma18020358

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a precision laboratory hydraulic press required for sulfide-based batteries? Achieve Critical Ion Conductivity

- What is the function of ceramic balls within a box furnace? Improve Coke Graphitization & System Safety

- What are the benefits of the improved circulating water vacuum pump? Save Costs and Go Green in Your Lab

- How do carbon composite conveyor belts affect brazing filler metal spreading? Achieve Precision Joint Stability

- Why is a vacuum drying oven essential for Pd-Ni/ZrO2 catalyst preparation? Ensure Uniform Metal Distribution

- What is the function of PTFE sealing rings in plastic pyrolysis? Ensure Safe, Anaerobic Material Decomposition

- What role does a laboratory graphite box play during the selenization of CBTSe thin films? Key Synthesis Benefits

- What is the function of a high-purity Argon (Ar) gas flow control system? Ensure Superior Nanowire Uniformity