At its core, the improved circulating water vacuum pump is an economical and environmentally friendly alternative to traditional oil-based vacuum pumps. It leverages water as its working medium to deliver a stable vacuum, eliminating the costs, maintenance, and pollution associated with vacuum oil while offering significant savings in water and electricity.

The fundamental advantage is its shift away from complex, oil-dependent mechanics to a simple, robust design using recycled water. This makes it a more cost-effective, safer, and lower-maintenance solution for most standard laboratory and research applications.

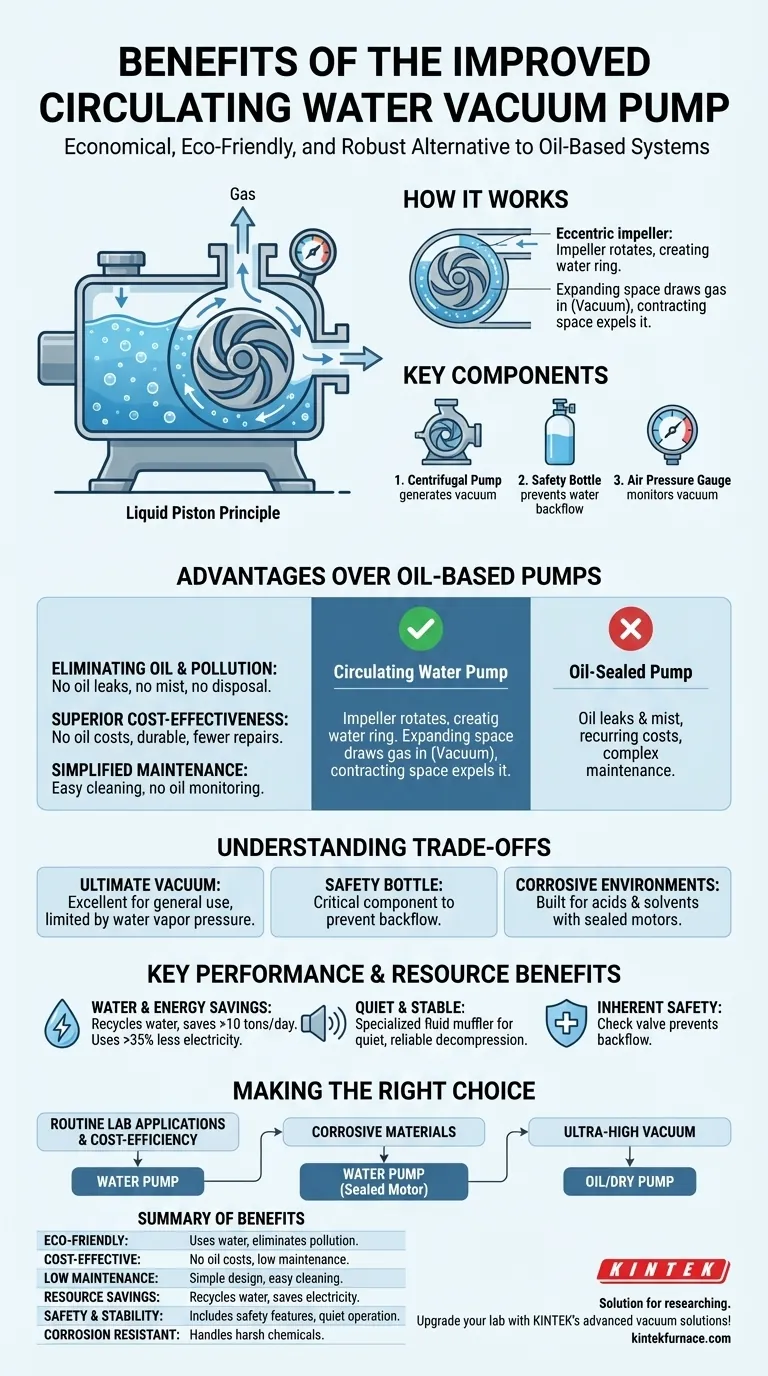

How a Circulating Water Vacuum Pump Works

To appreciate its benefits, it's essential to understand its operational principle, which is elegant in its simplicity.

The Core Principle: A "Liquid Piston"

The pump uses an eccentrically mounted impeller that spins within a cylindrical casing. As it rotates, it creates a ring of water that is forced against the outer wall by centrifugal force.

Because the impeller is off-center, the space between its blades and the water ring continuously expands and contracts. This action creates a "liquid piston" effect: as the space expands, it draws in gas (creating a vacuum), and as it contracts, it compresses and expels the gas.

The Key Components

A typical system consists of three main parts:

- The Pump: A centrifugal pump that moves water from a reservoir to generate the vacuum.

- A Safety Bottle: A crucial safety feature that prevents water from being accidentally sucked back into your experiment or system.

- An Air Pressure Gauge: This allows you to monitor the vacuum level, which typically reaches an ultimate vacuum around -0.098 MPa.

The Primary Advantages Over Oil-Based Pumps

The most significant benefits become clear when comparing this technology to traditional oil-sealed rotary vane pumps.

Eliminating Oil and Pollution

By using water, the pump completely avoids the problems of oil. There are no oil leaks, no oil mist contaminating the lab environment, and no need to dispose of used vacuum oil.

Superior Cost-Effectiveness

This design is more economical over its lifespan. There is no recurring cost for purchasing expensive vacuum oil, and the simpler mechanical structure makes the pump more durable and less prone to costly repairs.

Simplified Maintenance and Use

Cleaning is straightforward, and the overall operation is more convenient and flexible. Unlike oil pumps that require careful monitoring of oil levels and quality, a water pump simply requires a tank of water.

Understanding the Trade-offs

While highly effective, it's important to recognize the operational context for this type of pump.

Ultimate Vacuum Level

A circulating water pump provides an excellent vacuum for general chemistry, filtration, and distillation. However, its ultimate vacuum is limited by the vapor pressure of water. Applications requiring an extremely high or "deep" vacuum may still necessitate specialized dry scroll or turbomolecular pumps.

Reliance on the Safety Bottle

The safety bottle is not optional. It is a critical component that protects your work by preventing water from being drawn into the vacuum line if pressure fluctuates, ensuring the integrity of your experiment.

Designed for Corrosive Environments

Many models are specifically built to handle harsh conditions. With features like acid and solvent resistance and high-quality motors sealed against corrosive gases, they are often more resilient than standard oil pumps in challenging chemical applications.

Key Performance and Resource Benefits

Beyond the comparison to oil pumps, the design offers inherent efficiencies.

Significant Water and Energy Savings

Unlike aspirators that flush tap water directly to the drain, this pump recycles water from its reservoir. This can save over 10 tons of water in a single workday and uses over 35% less electricity compared to other vacuum pump types.

Quiet and Stable Operation

Modern designs often include a specialized fluid muffler. This, combined with the stable pressure generated by the water ring, results in significantly quieter operation and more reliable, stable decompression for sensitive procedures.

Inherent Safety Features

The design often incorporates a check valve to prevent backflow and ensure vacuum is maintained if the pump stops. This built-in safety measure adds another layer of reliability.

Making the Right Choice for Your Lab

Selecting the right pump depends entirely on your application's specific demands.

- If your primary focus is routine lab applications and cost-efficiency: This pump is an ideal choice due to its low maintenance, durability, and significant resource savings.

- If your primary focus is working with corrosive materials: Its resistance to acids, alkalis, and solvents, combined with a sealed motor, offers a safer and more durable solution.

- If your primary focus is achieving an ultra-high vacuum: You should evaluate specialized oil or dry pumps, as a water pump's vacuum is best suited for general-purpose applications.

By understanding these capabilities, you can confidently select a vacuum system that is not only effective but also economical and sustainable.

Summary Table:

| Benefit | Description |

|---|---|

| Eco-Friendly | Uses water instead of oil, eliminating pollution and oil disposal needs. |

| Cost-Effective | No vacuum oil costs, lower electricity use, and reduced maintenance expenses. |

| Low Maintenance | Simple design with easy cleaning and no oil monitoring required. |

| Resource Savings | Recycles water, saving over 10 tons daily and over 35% in electricity. |

| Safety & Stability | Includes safety bottle, check valve, and quiet, stable operation for reliable use. |

| Corrosion Resistant | Built to handle acids, solvents, and harsh environments with sealed motors. |

Upgrade your lab with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique needs. Contact us today to enhance efficiency, safety, and sustainability in your operations!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What maintenance is required after using the alumina furnace tube? Ensure Longevity and Purity in Your Lab

- Why is a gas mixing system essential for syngas annealing in copper powder production? Ensure Precise Embrittlement

- Why is the low thermal expansion of quartz important for laboratory applications? Ensure Safety and Precision in High-Heat Experiments

- Why are alumina crucibles and mother-powder necessary for LLZO sintering? Ensure High Ionic Conductivity

- How do multi-bore high-purity alumina tubes stabilize CV tests? Enhance Data Accuracy with KINTEK Solutions

- What is the function of a vacuum pump in tantalum capacitor recycling? Optimize Purity and Speed

- What is the key technological improvement in the circulating water vacuum pump? Discover the Self-Contained Closed-Loop System

- What is the function of Mass Flow Controllers (MFC) in the gas proportioning process for co-combustion experiments?