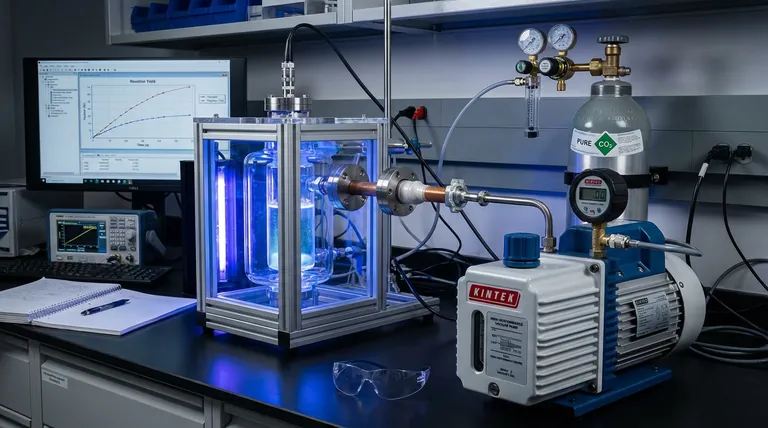

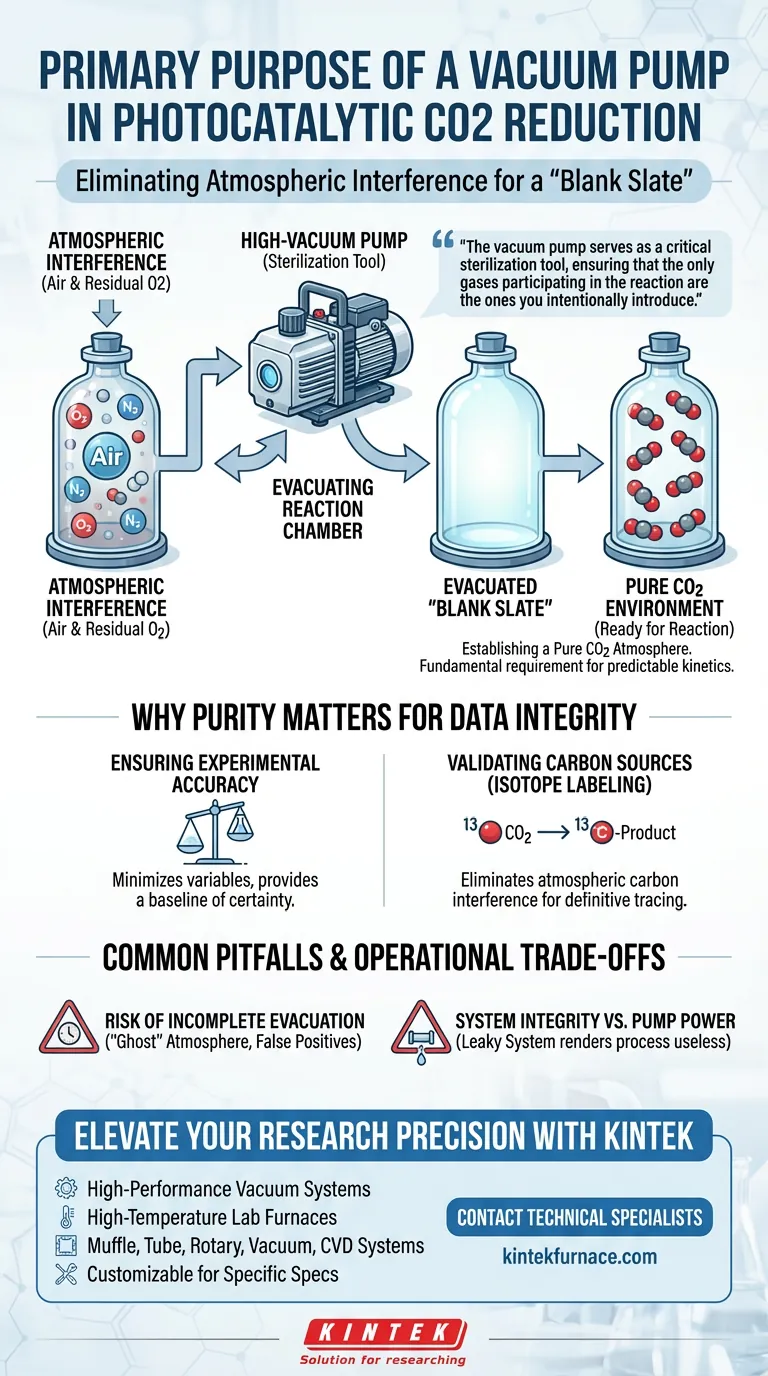

The primary purpose of a vacuum pump in photocatalytic CO2 reduction is to eliminate atmospheric interference by thoroughly evacuating the reaction chamber. By connecting a high-vacuum pump to the system's exhaust, researchers remove air and residual oxygen to create a "blank slate" before the reaction begins. This step is a prerequisite for establishing a pure CO2 environment.

In scientific experimentation, the validity of your results is defined by the purity of your inputs. The vacuum pump serves as a critical sterilization tool, ensuring that the only gases participating in the reaction are the ones you intentionally introduce.

Creating a Controlled Reaction Environment

Eliminating Residual Oxygen

The presence of oxygen is detrimental to reduction experiments. A high-vacuum pump functions to strip away the ambient air that naturally fills the reaction vessel.

By removing this residual oxygen, you prevent it from competing with CO2 for electrons or oxidizing the reduction products, which would skew the chemical outcomes.

Establishing a Pure CO2 Atmosphere

Once the air is evacuated, the chamber is refilled with the reactant gas. The vacuum process ensures that the environment transitions from a mix of atmospheric gases to a pure CO2 environment.

This purity is not merely a preference; it is a fundamental requirement for the reaction kinetics to proceed as predicted without external variables.

Why Purity Matters for Data Integrity

Ensuring Experimental Accuracy

The reliability of photocatalytic data hinges on knowing exactly what is inside the reactor. Any remaining atmospheric gases introduce variables that make it difficult to determine the true efficiency of the photocatalyst.

The vacuum pump minimizes these variables, providing a baseline of certainty for the experimental results.

Validating Carbon Sources via Isotope Labeling

One of the most specific applications mentioned in technical literature is carbon source isotope labeling. To prove that a fuel product (like methane or methanol) was generated from the introduced CO2 and not organic contaminants, researchers use isotopically labeled CO2 (e.g., $^{13}CO_2$).

If the system is not thoroughly evacuated, atmospheric carbon could contaminate the results. The vacuum pump eliminates this interference, allowing researchers to definitively trace the carbon path.

Common Pitfalls and Operational Trade-offs

The Risk of Incomplete Evacuation

A common error is underestimating the time or vacuum strength required. If the pump does not achieve a sufficient vacuum level, trace amounts of air remain.

This "ghost" atmosphere can lead to false positives or inconsistent yields between different experimental runs.

System Integrity vs. Pump Power

A powerful vacuum pump cannot compensate for a leaky system. The application of high vacuum puts stress on seals and joints.

Operators must ensure the reaction system is hermetically sealed; otherwise, the pump will continuously draw in outside air, rendering the purification process useless.

Ensuring Experimental Success

To maximize the reliability of your photocatalytic data, consider your specific experimental goals:

- If your primary focus is basic yield efficiency: Ensure the vacuum pump is capable of reaching pressures low enough to prevent oxygen from scavenging the photogenerated electrons.

- If your primary focus is mechanistic proof (Isotope Labeling): Prioritize a high-vacuum pump with a rigorous evacuation protocol to guarantee that absolutely no atmospheric carbon interferes with your isotopic tracing.

The vacuum pump is not just an accessory; it is the foundation of experimental reproducibility.

Summary Table:

| Feature | Role in CO2 Reduction | Impact on Experimental Success |

|---|---|---|

| Atmospheric Removal | Eliminates O2 and N2 from the chamber | Prevents electron scavenging and oxidative interference |

| Atmosphere Control | Facilitates transition to pure CO2 environment | Ensures reaction kinetics proceed without external variables |

| Data Integrity | Enables accurate Carbon Source Isotope Labeling | Confirms fuel products originate solely from introduced CO2 |

| Reproducibility | Establishes a consistent, clean baseline | Minimizes false positives and experimental variability |

Elevate Your Research Precision with KINTEK

Don't let atmospheric impurities compromise your photocatalytic data. KINTEK provides high-performance vacuum systems and high-temperature laboratory furnaces designed for the rigorous demands of CO2 reduction and material synthesis.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory specifications. Our technology ensures the hermetic integrity and precise control required for definitive isotope labeling and kinetic studies.

Ready to optimize your experimental setup? Contact our technical specialists today to discover how KINTEK can enhance your lab's efficiency and data reliability.

Visual Guide

References

- Facilitated Charge Transfer Endowed by Zn–O Bridge of Phthalocyanine‐Based Hollow Tandem S‐Scheme Heterojunction for Photocatalytic Fuel Production. DOI: 10.1002/sstr.202500166

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- Why is a vacuum pumping system essential for DD6 alloy and ceramic shell experiments? Achieve High-Purity Results

- What is the primary function of a constant temperature drying oven? Master S53P4 Bioactive Glass Gel Integrity

- What is the significance of using a laboratory electric thermostatic blast drying oven for biomass briquette moisture control?

- What considerations lead to the selection of a corundum crucible for CVD sulfurization? Ensure Peak Sample Purity

- Why are vacuum-sealed quartz tubes required for SnSe melting? Ensure Purity & Stoichiometry

- How is a vacuum pump system used to simulate high-altitude gasification conditions? Replicate 3000m Pressure Levels

- What is the key technological improvement in the circulating water vacuum pump? Discover the Self-Contained Closed-Loop System

- What maintenance is required after using the alumina furnace tube? Ensure Longevity and Purity in Your Lab