Proper maintenance of an alumina furnace tube is essential for ensuring its longevity and the purity of your experimental results. The most critical step after any use is to ensure the inside of the tube is perfectly clean, with no residual sample material left behind. This immediate action prevents both chemical contamination in future runs and the creation of localized stress points that can lead to tube failure.

The core principle of alumina tube care extends beyond simple cleaning. The material's primary weakness is its poor resistance to thermal shock. Therefore, longevity is achieved by meticulously controlling heating and cooling rates to prevent the formation of catastrophic cracks.

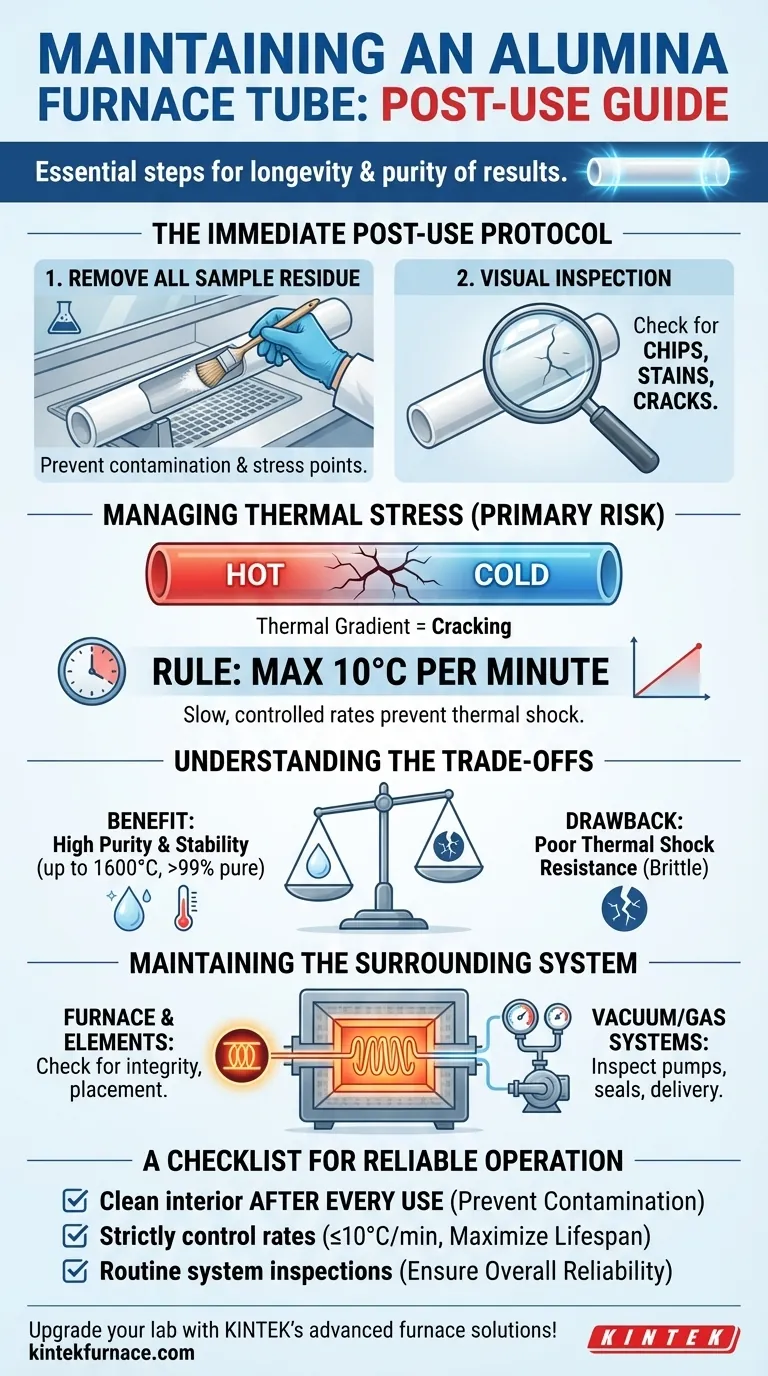

The Immediate Post-Use Protocol

Your post-use procedure sets the stage for the next successful operation. It is a non-negotiable step in a professional laboratory environment.

Removing All Sample Residue

After the furnace has cooled completely, you must clean the tube's interior. Any leftover material can react with the alumina or the next sample at high temperatures, compromising your results.

These residues can also create hot spots or stress concentrations during the next heating cycle, increasing the risk of the tube cracking.

Visual Inspection for Damage

After cleaning, perform a quick visual inspection. Look for any new chips, stains, or hairline cracks. Catching damage early allows you to assess if the tube is still safe for use or needs to be replaced, preventing a catastrophic failure during a high-temperature run.

Managing Thermal Stress: The Key to Longevity

While cleaning prevents contamination, managing thermal stress is what prevents physical destruction of the tube. This is the most common failure mode for high-purity ceramic components.

Why Thermal Shock is the Primary Risk

Alumina (Al₂O₃) has exceptional high-temperature stability and chemical inertness, but it is a brittle ceramic. It does not flex or yield under stress.

Rapid changes in temperature create a thermal gradient across the material—meaning the inside and outside surfaces are at different temperatures. This differential expansion or contraction induces immense internal stress, which can easily exceed the material's strength and cause it to crack.

Adhering to Strict Heating and Cooling Rates

To prevent thermal shock, you must always adhere to a slow, controlled heating and cooling profile.

As a rule, heating and cooling rates should not exceed 10°C per minute. For sensitive processes or very large tubes, a rate of 5°C per minute is even safer. Abruptly opening the furnace at high temperatures to cool it down will almost certainly destroy the tube.

The Initial Firing Cycle

For a brand-new tube, it is critical to perform an initial pre-firing. This involves slowly heating the empty tube (e.g., 5-8°C/min) to a high temperature like 1300°C and holding it for a period to relieve any manufacturing-induced stresses.

Understanding the Trade-offs

Choosing alumina is a deliberate engineering decision with clear benefits and a significant drawback you must manage.

The Benefit: Purity and Stability

You use an alumina tube because it is highly pure (often >99%) and chemically inert, and it can withstand continuous working temperatures up to 1600°C. This ensures that the tube itself does not become a variable in your experiment.

The Drawback: Inherent Brittleness

The trade-off for this high-temperature stability is the material's poor thermal shock resistance. You are trading toughness for chemical and thermal purity. Acknowledging this limitation is fundamental to using the equipment correctly.

Maintaining the Surrounding System

The furnace tube does not operate in isolation. The health of the entire system impacts its performance and lifespan.

Furnace and Heating Element Health

Regularly inspect the furnace itself. Check that heating elements are intact and positioned correctly. A failing or misplaced element can cause uneven heating, creating dangerous hot spots on your alumina tube.

Vacuum and Gas System Integrity

If you use a vacuum or controlled atmosphere, your maintenance plan must include the pumps, seals, and gas delivery systems. Follow the manufacturer’s guidelines for pump oil changes and seal inspections to ensure a stable and pure operating environment.

A Checklist for Reliable Operation

To ensure your equipment remains a reliable asset, tailor your maintenance focus to your primary goal.

- If your primary focus is preventing contamination: Thoroughly clean the tube's interior after every single use to remove all sample residue.

- If your primary focus is maximizing tube lifespan: Strictly control all heating and cooling rates, never exceeding 10°C/min to avoid catastrophic thermal shock.

- If your primary focus is overall system reliability: Implement a routine schedule to inspect the entire furnace, including heating elements, seals, and atmosphere control systems.

Disciplined and consistent maintenance is the only way to protect your investment and guarantee the integrity of your work.

Summary Table:

| Maintenance Step | Key Action | Purpose |

|---|---|---|

| Post-Use Cleaning | Remove all sample residue | Prevent chemical contamination and stress points |

| Visual Inspection | Check for chips, stains, or cracks | Early detection of damage to avoid failure |

| Thermal Stress Management | Control heating/cooling rates (≤10°C/min) | Prevent thermal shock and cracking |

| System Health Check | Inspect furnace, elements, and atmosphere systems | Ensure even heating and stable operation |

Upgrade your lab's performance with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your maintenance protocols and boost efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing