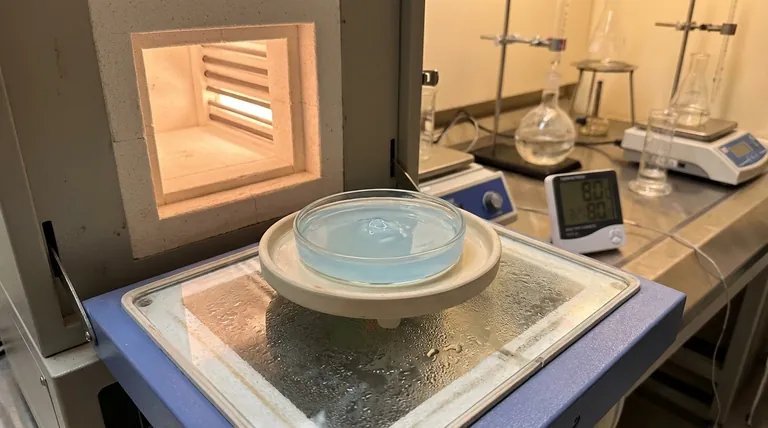

The primary function of the constant temperature drying oven is to provide a controlled thermal environment for the gentle removal of solvents. By maintaining a specific, steady temperature over an extended period, the oven extracts residual water and ethanol from the S53P4 bioactive glass gel pores. This step is the critical line of defense against structural failure, ensuring the material remains intact before it faces higher temperatures.

Core Takeaway The drying oven acts as a structural stabilizer rather than just a dehydrator. Its main goal is to moderate the rate of solvent evaporation to prevent the high capillary stresses that cause wet gels to collapse or crack during the transition to a dry solid.

The Mechanics of Controlled Drying

Gentle Solvent Extraction

The immediate role of the oven is to remove the liquid phase residing within the gel's pore network.

For S53P4 bioactive glass gels, this liquid typically consists of residual water and solvents like ethanol.

The oven creates a consistent thermal atmosphere that encourages these liquids to evaporate at a steady, manageable rate.

Prevention of Rapid Evaporation

Uncontrolled drying is the enemy of gel integrity.

If solvents evaporate too quickly, the differential pressure within the pores can destroy the material.

The constant temperature oven ensures the evaporation is uniform, preventing the "shock" that occurs with rapid environmental changes.

Preserving Structural Integrity

Mitigating Capillary Stress

As liquid leaves the pores of a gel, it exerts capillary forces on the pore walls.

If the drying is aggressive, these forces become strong enough to crush the delicate pore network.

By controlling the temperature, the oven keeps these forces below the material's yield strength, preventing structural collapse.

Avoiding Cracking and Agglomeration

The primary reference highlights that this step is critical for preventing severe cracking.

Rapid solvent loss leads to shrinkage gradients—where the outside dries faster than the inside—causing the gel to fracture.

Furthermore, controlled drying prevents hard agglomeration, preserving the microporous structure that is vital for the bioactive glass's reactivity.

Preparation for Stabilization

The drying oven is essentially a pre-treatment for subsequent high-temperature steps.

If a gel containing significant moisture or solvent is placed directly into a high-temperature furnace, the liquid will boil instantly.

This would result in catastrophic structural failure; the drying oven ensures the gel is "dry" enough to safely withstand stabilization or sintering.

Understanding the Trade-offs

Time vs. Structural Fidelity

The most common pitfall in this process is prioritizing speed over stability.

Increasing the oven temperature will dry the gel faster, but it exponentially increases the risk of network collapse and cracking.

You are trading processing time for material quality; for bioactive glass, preserving the pore structure is usually worth the extra time.

Uniformity vs. Throughput

Loading the oven too heavily can create uneven thermal zones.

While the oven is designed for "constant temperature," blocking airflow with too many samples can lead to localized humidity pockets.

This results in inconsistent drying rates across the batch, leading to variability in the final material properties.

Making the Right Choice for Your Goal

To ensure the S53P4 bioactive glass gel performs as intended, apply the drying process with the following goals in mind:

- If your primary focus is Structural Integrity: Prioritize a lower temperature setting for a longer duration to minimize capillary stress and preserve the maximum amount of porosity.

- If your primary focus is Reproducibility: Ensure the oven is not overloaded and that samples are spaced evenly to guarantee that every gel experiences the exact same thermal history.

The constant temperature drying oven is not merely removing water; it is defining the final architecture of your bioactive material.

Summary Table:

| Function | Mechanism | Benefit to S53P4 Gel |

|---|---|---|

| Thermal Stability | Constant, controlled heat | Prevents evaporation 'shock' and material collapse |

| Solvent Extraction | Gentle removal of water/ethanol | Maintains structural integrity of the pore network |

| Stress Mitigation | Reduced capillary forces | Minimizes shrinkage gradients and severe cracking |

| Pre-treatment | Removal of volatiles | Prepares material for safe high-temperature sintering |

Optimize Your Material Synthesis with KINTEK

Precision is paramount when handling delicate S53P4 bioactive glass gels. KINTEK provides high-performance thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered to maintain the uniform thermal environments required for structural stability.

Backed by expert R&D and manufacturing, our lab high-temp furnaces are fully customizable to meet your unique drying and stabilization needs, ensuring your materials remain crack-free and highly reactive.

Ready to elevate your lab's efficiency? Contact us today to find the perfect customizable furnace solution!

References

- Jian Zheng, Julian R. Jones. Sol‐gel derived S53P4 bioactive glass. DOI: 10.1111/jace.70090

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How do vacuum systems assist in pure thin film growth? Enhance PLD Chemical Purity with Turbo-Molecular Pumps

- Why is a high vacuum pumping system required for Bi2Se3-Nd2Se3 alloying? Ensure Purity in Rare Earth Synthesis

- What are the functions of high-purity, high-strength graphite molds in SPS? Optimize Al2O3-TiC Ceramic Sintering

- Why is a high-purity graphite box required for CZTS sulfurization? Protect Thin Film Integrity and Crystallinity

- What is the role of a Teflon-lined autoclave in CeO2 synthesis? Achieve Pure, Monodisperse Nanomaterials

- Why is temperature resistance important for alumina ceramic furnace tubes? Ensure Safety and Performance in High-Temp Processes

- What is the function of a vacuum system in PLD? Ensure High-Density, Pure Electrolyte Thin Films

- Why is a high-purity graphite crucible preferred for (AgCu)0.999Te0.69Se0.3S0.01 preparation? Ensure Peak Purity.