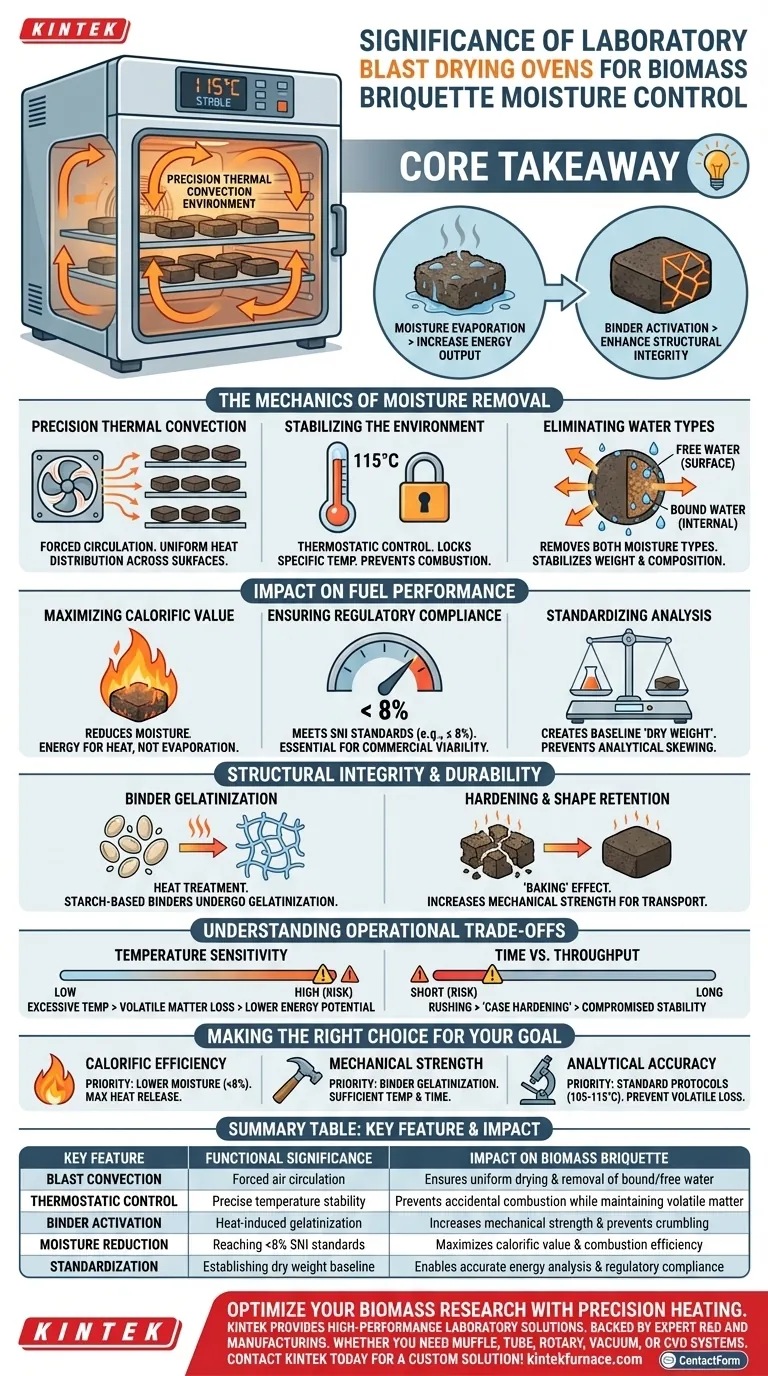

The significance of a laboratory electric thermostatic blast drying oven lies in its ability to provide a precise, stable thermal convection environment that systematically removes bound and free water from biomass briquettes. By maintaining controlled temperatures (typically between 100°C and 115°C), the oven ensures moisture levels drop to compliant standards (such as SNI ≤ 8%), which is the single most critical factor in maximizing the fuel's combustion efficiency and calorific value.

Core Takeaway While the primary function of the blast drying oven is to force moisture evaporation to increase energy output, it serves a critical secondary purpose: the heat treatment activates starch-based binders. This process finalizes the briquette's shape, transforming a fragile molded sample into a mechanically strong, durable fuel source.

The Mechanics of Moisture Removal

Precision Thermal Convection

The term "blast drying" refers to the forced circulation of hot air. Unlike static ovens, this technology ensures that heat is distributed evenly across every surface of the briquette.

Stabilizing the Environment

"Thermostatic" control allows you to lock in specific temperatures, such as 115°C, without fluctuation. This stability is essential for removing water without accidentally initiating combustion or charring the biomass material.

Eliminating Water Types

Effective drying requires removing both free water (surface moisture) and bound water (internal moisture trapped in the cellular structure). The sustained heat and airflow penetrate the briquette to expel both, ensuring the weight and composition are stabilized for accurate analysis.

Impact on Fuel Performance

Maximizing Calorific Value

Water does not burn; it absorbs heat to evaporate. By reducing moisture content, the oven ensures that the energy released during combustion is used for heat generation rather than water evaporation.

Ensuring Regulatory Compliance

For biomass briquettes to be commercially viable, they must meet strict standards. The drying process is the final step to ensure moisture levels fall below thresholds like the SNI standard of 8%.

Standardizing Analysis

To accurately measure the potential energy of a fuel source, external variables must be removed. The drying oven creates a baseline "dry weight," preventing residual moisture from skewing subsequent calorific value analyses.

Structural Integrity and Durability

Binder Gelatinization

This is often the overlooked benefit of the drying process. The heat treatment causes starch-based binders within the mixture to undergo gelatinization.

Hardening and Shape Retention

As the binders gelatinize and the moisture evaporates, the briquette hardens significantly. This "baking" effect creates the mechanical strength required for the briquette to withstand transport and handling without crumbling.

Understanding Operational Trade-offs

Temperature Sensitivity

While heat is necessary, excessive temperature can be detrimental. Setting the oven too high can cause volatile matter to evaporate along with the water, artificially lowering the fuel's energy potential before it is ever used.

Time vs. Throughput

Thorough drying takes time—often several hours. Rushing this process by increasing heat leads to "case hardening," where the outside is dry but the inside remains wet, compromising the stability of the briquette.

Making the Right Choice for Your Goal

To maximize the utility of your drying process, align your oven settings with your specific objectives:

- If your primary focus is Calorific Efficiency: Prioritize lower moisture targets (e.g., <8%) to ensure maximum heat release during combustion.

- If your primary focus is Mechanical Strength: Ensure the temperature is sufficient to fully gelatinize the binder, maintaining heat duration long enough to harden the core.

- If your primary focus is Analytical Accuracy: Adhere strictly to standard temperature protocols (e.g., 105°C - 115°C) to prevent the loss of volatile organic compounds.

By controlling the drying environment, you are not just removing water; you are engineering a higher-quality, more reliable fuel source.

Summary Table:

| Key Feature | Functional Significance | Impact on Biomass Briquette |

|---|---|---|

| Blast Convection | Forced air circulation | Ensures uniform drying and removal of bound/free water |

| Thermostatic Control | Precise temperature stability | Prevents accidental combustion while maintaining volatile matter |

| Binder Activation | Heat-induced gelatinization | Increases mechanical strength and prevents crumbling |

| Moisture Reduction | Reaching <8% SNI standards | Maximizes calorific value and combustion efficiency |

| Standardization | Establishing dry weight baseline | Enables accurate energy analysis and regulatory compliance |

Optimize Your Biomass Research with Precision Heating

Ensuring the structural integrity and energy density of your fuel samples requires more than just heat—it requires control. KINTEK provides high-performance laboratory solutions backed by expert R&D and manufacturing. Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to meet your unique moisture control and heat treatment needs.

Ready to enhance your lab’s efficiency and analytical accuracy? Contact KINTEK today for a custom solution!

Visual Guide

References

- Adam Yonanda, Elvianto Dwi Daryono. Optimization of Natural Adhesive Type and Concentration on Characteristics of Corn Cob Biobriquettes. DOI: 10.70609/gtech.v9i1.6194

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- Why is vacuum sealing in quartz tubes essential for Cr0.82Mn0.18Ge? Ensure Stoichiometry & Purity

- What role does the planetary ball mill play in LLZO mixing? Unlock High-Performance Solid-State Electrolyte Synthesis

- Why are high-purity ceramic boats used for V2O5 and VSe2 deposition? Ensure Film Purity and Thermal Stability

- What role does a high-precision lab stirring device play in KR experiments? Optimizing Desulfurization Simulation

- Why is a high-vacuum system required for sealing quartz tubes? Achieve Ultra-Pure Chalcogenide Alloy Synthesis

- What role does a graphite crucible play during alloy and ceramic shell interaction experiments? Optimize Your Lab Results

- What key functions do high-strength graphite molds perform? Optimize Al2O3/TiC Hot Press Sintering Success

- What function does a PTFE liner serve in NiWO4 synthesis? Ensure Purity & Prevent Corrosion in Hydrothermal Reactors