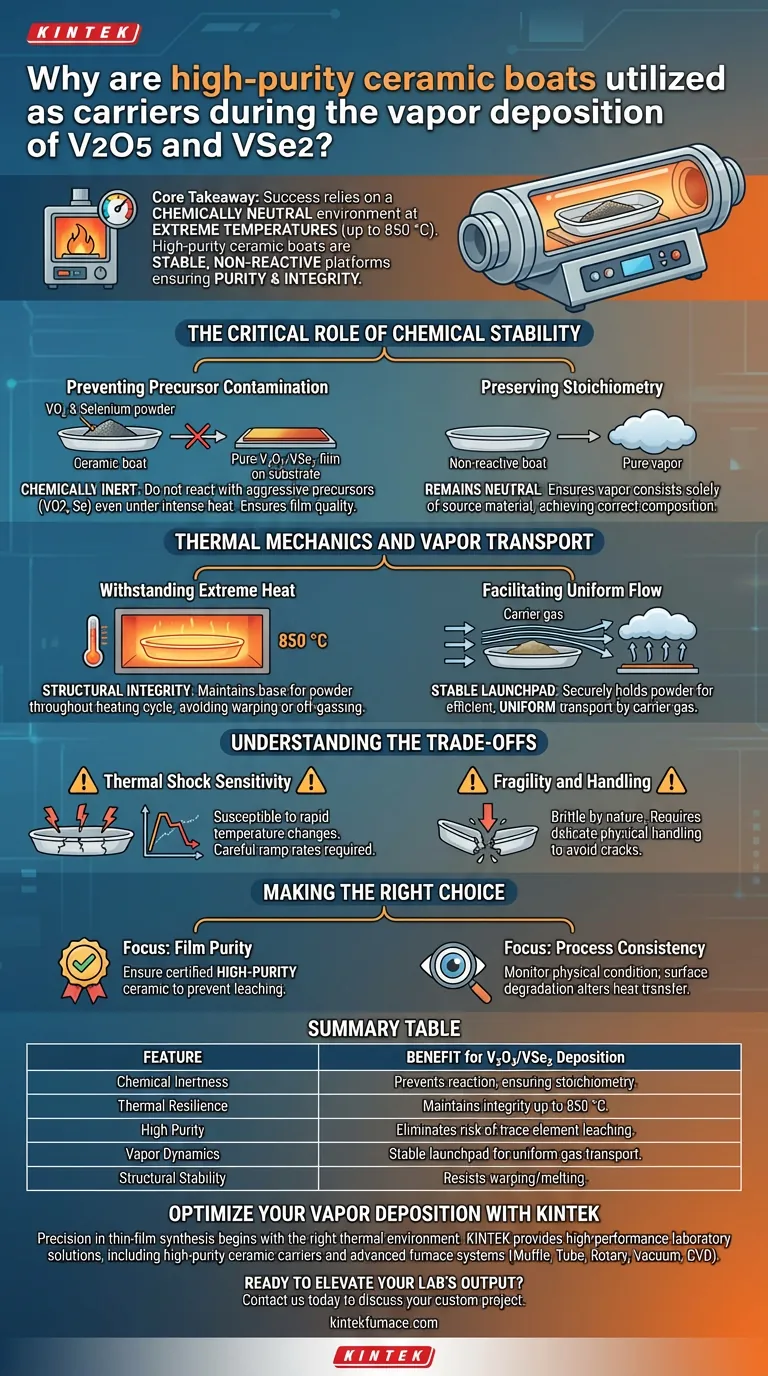

High-purity ceramic boats are chosen for their inertness and thermal resilience. During the vapor deposition process, these vessels must withstand temperatures reaching 850 °C without degrading. Crucially, they do not chemically react with solid precursors—specifically Vanadium Dioxide (VO2) or Selenium (Se) powder—ensuring the purity and integrity of the resulting V2O5 or VSe2 films.

Core Takeaway The success of vapor deposition relies on maintaining a chemically neutral environment at extreme temperatures. High-purity ceramic boats act as stable, non-reactive platforms that prevent precursor contamination while facilitating the uniform transport of vapors to the substrate.

The Critical Role of Chemical Stability

Preventing Precursor Contamination

In vapor deposition, the purity of your source material dictates the quality of your final film.

High-purity ceramics are selected because they are chemically inert. They will not react with aggressive precursors like Selenium powder or VO2, even under intense heat.

Preserving Stoichiometry

If a container reacts with the precursor, it consumes the source material and introduces impurities.

By remaining neutral, ceramic boats ensure that the vapor generated consists solely of the intended source material. This is essential for achieving the correct chemical composition in V2O5 and VSe2 structures.

Thermal Mechanics and Vapor Transport

Withstanding Extreme Heat

The deposition process for these materials frequently requires temperatures up to 850 °C.

At these levels, many materials warp, melt, or off-gas. High-purity ceramics maintain their structural integrity, providing a secure base for the solid powder throughout the heating cycle.

Facilitating Uniform Flow

The boat serves as more than just a container; it is the launchpad for the vapor.

It holds the solid powder securely within the stream of the carrier gas. This positioning allows the vapors to be picked up efficiently and transported uniformly toward the substrate, promoting an even film coating.

Understanding the Trade-offs

Thermal Shock Sensitivity

While ceramics handle high heat well, they are often susceptible to rapid temperature changes.

Heating or cooling the system too quickly can cause the boat to crack or shatter. Careful ramp-up and cool-down rates are necessary to preserve the equipment.

Fragility and Handling

High-purity ceramics are brittle by nature.

They require delicate physical handling during loading and cleaning. A microscopic crack from mishandling can expand at 850 °C, potentially spilling molten or powdered precursor into the furnace.

Making the Right Choice for Your Process

- If your primary focus is Film Purity: Ensure the ceramic grade is certified high-purity to prevent trace elements from leaching into the VO2 or Se vapors.

- If your primary focus is Process Consistency: Monitor the physical condition of the boats closely; surface degradation can alter heat transfer and vapor generation rates.

The ceramic boat is a passive but critical component; its stability is the foundation of a successful deposition.

Summary Table:

| Feature | Benefit for V2O5/VSe2 Deposition |

|---|---|

| Chemical Inertness | Prevents reaction with VO2 or Se powder, ensuring film stoichiometry. |

| Thermal Resilience | Maintains structural integrity at temperatures up to 850 °C. |

| High Purity | Eliminates risk of trace element leaching into the vapor stream. |

| Vapor Dynamics | Serves as a stable launchpad for uniform gas transport to substrates. |

| Structural Stability | Resists warping and melting during long heating cycles. |

Optimize Your Vapor Deposition with KINTEK

Precision in thin-film synthesis begins with the right thermal environment. KINTEK provides high-performance laboratory solutions, including high-purity ceramic carriers and advanced furnace systems. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous thermal demands of your V2O5 and VSe2 research.

Ready to elevate your lab's output? Contact us today to discuss your custom project needs and experience the KINTEK advantage in material science.

Visual Guide

References

- Gangtae Jin. Controlled Vapor-Phase Synthesis of VSe2 via Selenium-Driven Gradual Transformation of Single-Crystalline V2O5 Nanosheets. DOI: 10.3390/nano15070548

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why are high-purity alumina crucibles preferred? Secure Unmatched Purity and Data Integrity in Lab Synthesis

- What are the limitations of ultra-pure alumina porcelain tubes? Manage Brittleness for Reliable High-Temp Use

- What are the alternative names for a Laboratory Furnace? Find the Right High-Temperature Tool for Your Lab

- How does the circulating water multifunctional vacuum pump create a vacuum? Discover Its Oil-Free Mechanism

- Why are high-purity alumina or ceramic boats required in a tube furnace? Protect Your Lab Equipment & Ensure Purity

- What functions do graphite molds perform during the vacuum hot pressing of A356/SiCp? Optimize Your Material Density

- What is a vacuum chamber good for? Mastering Material Processing with Environmental Control

- Why is a graphite crucible used for melting Al-Mg-Si alloys? Superior Purity & Thermal Efficiency