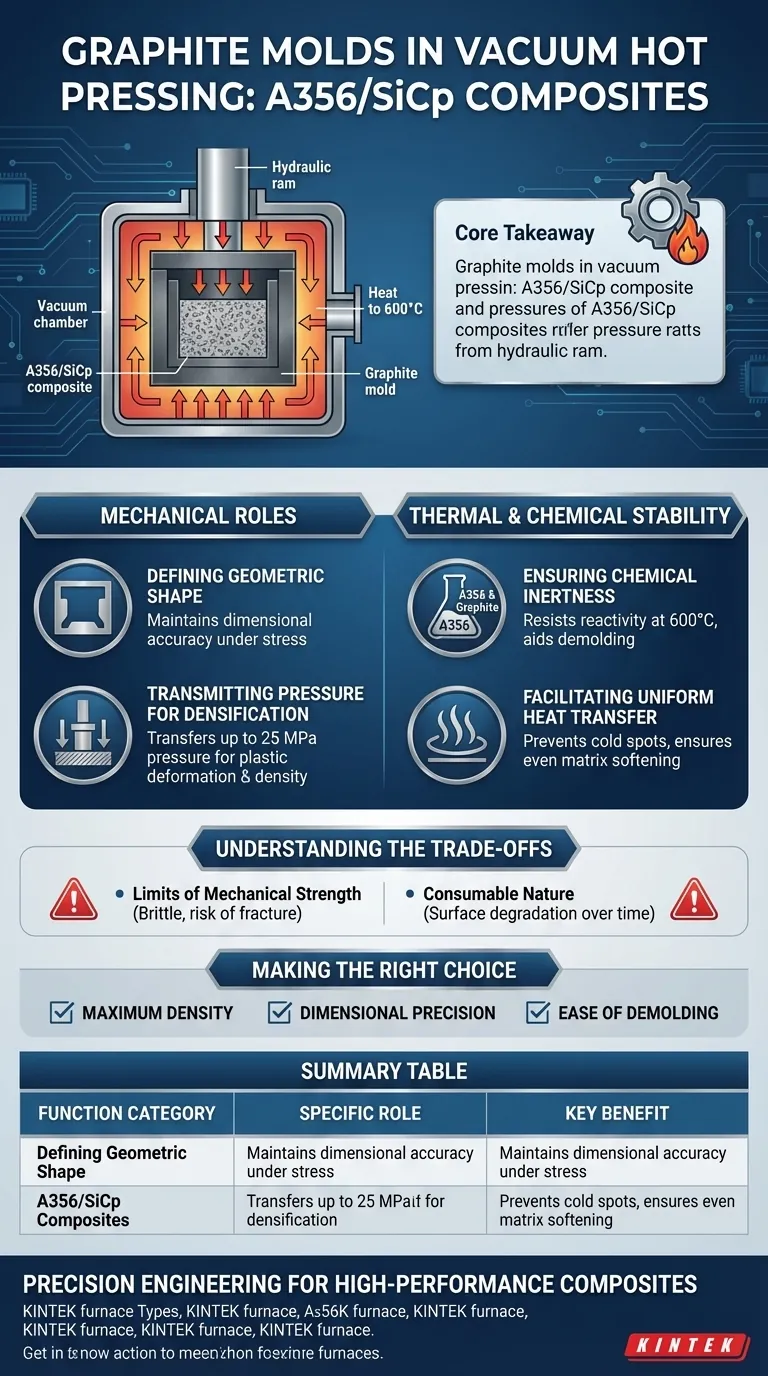

Graphite molds function as the primary structural and thermodynamic interface during the vacuum hot pressing of A356/SiCp composites. They act as high-temperature resistant forming containers that maintain chemical stability at approximately 600°C while withstanding mechanical pressures up to 25 MPa. Beyond simple containment, these molds are the critical medium for transmitting pressure to assist in the plastic deformation and densification of the powder particles.

Core Takeaway The graphite mold is not merely a passive container; it is an active processing tool that converts hydraulic pressure into material density while maintaining dimensional accuracy under high thermal stress. Its dual ability to transmit force and conduct heat without chemically reacting with the aluminum matrix is essential for creating structurally sound A356/SiCp composites.

The Mechanical Roles of the Mold

Defining Geometric Shape Under Stress

The most immediate function of the graphite mold is to define the final geometric shape of the composite billet.

Unlike standard casting, this process involves high pressure. The mold must maintain its structural rigidity to ensure the dimensional accuracy of the final part, preventing bulging or warping even as the aluminum matrix softens.

Transmitting Pressure for Densification

The mold serves as a pressure-transmitting medium between the hydraulic ram and the composite mixture.

It transfers external mechanical pressure (up to 25 MPa) directly to the A356/SiC powder. This pressure is required to facilitate plastic deformation, closing the voids between particles and ensuring a dense, non-porous microstructure.

Thermal and Chemical Stability Functions

Ensuring Chemical Inertness

At the processing temperature of 600°C, the A356 aluminum alloy becomes highly reactive.

The graphite mold provides chemical stability in this vacuum environment. It resists severe chemical adhesion with the aluminum matrix, which preserves the purity of the composite surface and significantly facilitates the demolding operation after sintering.

Facilitating Uniform Heat Transfer

Graphite possesses excellent thermal conductivity.

The mold acts as a thermal conduit, transferring heat uniformly from the heating elements to the internal metal powder. This ensures that the A356 matrix melts or softens evenly throughout the billet, preventing "cold spots" that could lead to structural weaknesses.

Understanding the Trade-offs

Limits of Mechanical Strength

While graphite is robust, it is brittle compared to steel.

If the applied hydraulic pressure exceeds the mold's specific compressive strength (or if the pressure is applied unevenly), the mold can fracture. You must balance the desire for higher densification pressure against the mechanical limits of the specific graphite grade used.

Consumable Nature

Graphite molds are often considered consumables in high-performance applications.

Despite their stability, repeated cycling between high heat (600°C) and room temperature, combined with high-pressure friction, eventually degrades the mold's surface finish and dimensional tolerances.

Making the Right Choice for Your Goal

To optimize your vacuum hot pressing process for A356/SiCp composites, consider these specific priorities:

- If your primary focus is Maximum Density: Prioritize the mold’s wall thickness and graphite grade to ensure it can withstand pressures at the upper limit (near 25 MPa) to maximize plastic deformation.

- If your primary focus is Dimensional Precision: Ensure the graphite grade chosen has high thermal stability to prevent expansion or distortion during the 600°C heating phase.

- If your primary focus is Ease of Demolding: Verify the surface finish of the graphite and its chemical compatibility to prevent mechanical interlocking or chemical bonding with the aluminum matrix.

The success of your composite relies on viewing the graphite mold not as a bucket, but as a precision instrument for applying heat and pressure.

Summary Table:

| Function Category | Specific Role in Process | Key Benefit |

|---|---|---|

| Mechanical | Pressure Transmission (up to 25 MPa) | Facilitates plastic deformation & densification |

| Structural | Geometric Containment | Ensures dimensional accuracy of the composite billet |

| Thermal | Uniform Heat Transfer | Prevents cold spots and ensures even matrix softening |

| Chemical | High-Temperature Inertness | Prevents adhesion with A356 alloy & aids demolding |

Precision Engineering for High-Performance Composites

Achieving the perfect balance of density and dimensional accuracy in A356/SiCp composites requires equipment designed for extreme environments. KINTEK provides industry-leading vacuum hot pressing solutions supported by expert R&D and manufacturing.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to your unique material specifications.

Ready to elevate your material science? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a covered aluminum crucible necessary for g-C3N5 thermal polycondensation? Optimize Your Synthesis Atmosphere

- Why are insulation ceramic plugs used inside the alumina furnace tube? Ensure Stable Heating and Prevent Tube Cracking

- Why is a molybdenum crucible considered an ideal choice for quartz melting? High-Purity Solutions at 2000°C

- What are the advantages of using open corundum crucibles for thermal analysis? Accurate Biomass & Coal Data

- What role does an alumina crucible play during the gas nitriding process for stainless steel? Ensure Surface Purity

- What are the technical considerations for selecting a graphite crucible? Expert Insights for Molten Salt Electrolysis

- Why is a heat-resistant crucible indispensable for magnesium purification? Ensuring Purity and Efficiency in Vacuum Sublimation

- What is the function of a high-purity porcelain crucible? Expert Guide to Chromium-Doped Borosilicate Glass Preparation