The primary limitation of ultra-pure alumina porcelain tubes is their poor thermal shock resistance. This means they are highly susceptible to cracking or fracturing when subjected to rapid and extreme temperature changes, which can lead to critical failures like leaks in seals and insulators.

While prized for its exceptional hardness, high-temperature stability, and corrosion resistance, alumina's rigid crystalline structure makes it inherently brittle. The key to successfully using alumina is to leverage its strengths while carefully managing its critical vulnerability to thermal shock.

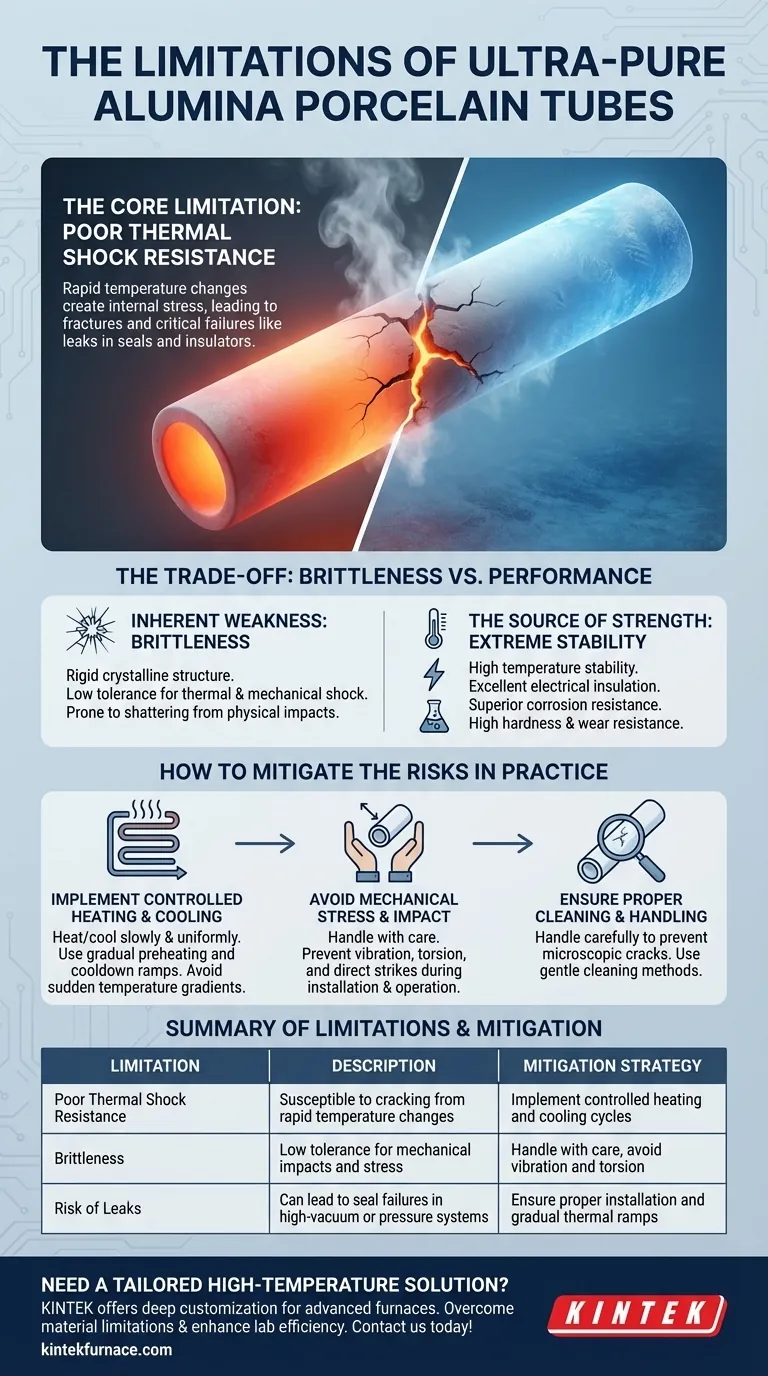

The Core Limitation: Poor Thermal Shock Resistance

The most significant factor you must account for when working with alumina ceramics is their behavior under thermal stress. This single property often dictates its suitability for an application.

What is Thermal Shock?

Thermal shock occurs when a rapid temperature change creates a steep temperature gradient within the material. One part of the tube expands or contracts much faster than another, generating internal stresses that can exceed the material's strength, causing it to crack.

Why Alumina is Susceptible

Ultra-pure alumina achieves its high strength and stability through a dense, rigid crystalline structure formed during high-temperature sintering. This same rigidity is its weakness. Unlike metals that can bend or deform under stress, alumina is brittle and does not yield. When stress from a thermal gradient builds, the material fractures instead of flexing.

Practical Consequences of Failure

The consequences of thermal shock failure are not minor. As the references note, this can cause leaks in insulators and porcelain sealing parts. In a high-vacuum or high-pressure system, a cracked tube leads to immediate and complete failure of the environment you are trying to maintain.

Understanding the Trade-offs: Brittleness vs. Performance

The decision to use alumina is a classic engineering trade-off. You are exchanging resilience to thermal and mechanical shock for elite performance in other areas.

The Source of Strength: Extreme Stability

Alumina tubes offer a combination of properties that make them indispensable for demanding applications. They exhibit:

- High Temperature Stability: They maintain their structural integrity at very high temperatures.

- Excellent Electrical Insulation: They are one of the best electrical insulators, even at high temperatures.

- Superior Corrosion Resistance: They are highly resistant to chemical attack from acids and other corrosive agents.

- High Hardness and Wear Resistance: Alumina is an extremely hard material, making it resistant to abrasion and wear.

The Inherent Weakness: Brittleness

These strengths are a direct result of alumina's rigid ceramic nature. This rigidity means it has very low tolerance for both thermal shock (as discussed) and mechanical shock (physical impacts). Dropping an alumina tube or striking it with a hard object will likely cause it to shatter.

A Note on Contradictory Data

Some sources may describe alumina as having "good" thermal shock resistance. This is highly relative. Compared to materials that cannot withstand high temperatures at all, it is superior. However, within the world of advanced ceramics, its susceptibility to thermal shock is a well-known and critical design constraint that must be actively managed.

How to Mitigate the Risks in Practice

You can use alumina successfully in thermally dynamic environments, but only by implementing strict operational procedures.

Implement Controlled Heating and Cooling

This is the most critical mitigation strategy. The tube must be heated and cooled as slowly and uniformly as possible. Avoid introducing a hot tube into a cold environment or vice-versa. For electrical contacts or furnaces, this means implementing a gradual preheating and cooldown ramp to prevent the destructive impact of sudden temperature changes.

Avoid Mechanical Stress and Impact

Handle alumina components with care. Their hardness is not toughness. Ensure that parts are not subject to vibration, torsion, or direct impact during installation or operation.

Ensure Proper Cleaning and Handling

When cleaning is required, methods like ultrasonic cleaning can be effective, but parts must be handled carefully. Any pre-existing microscopic cracks from handling can become the origin point for a catastrophic failure under thermal stress.

Making the Right Choice for Your Application

Use these guidelines to determine if ultra-pure alumina is the correct choice for your project.

- If your primary focus is a stable, high-temperature, and corrosive environment: Alumina is an excellent choice, provided you can guarantee slow and controlled heating and cooling cycles.

- If your application involves rapid thermal cycling or frequent temperature shocks: You should strongly consider alternative materials (like silicon nitride or certain metal alloys) or be prepared to invest in sophisticated thermal management systems.

- If your goal is high electrical insulation in a harsh chemical or thermal environment: Alumina is a top-tier material, but you must design the entire system to protect the component from both mechanical and thermal shock.

By understanding this fundamental trade-off, you can harness the exceptional properties of alumina while avoiding its critical failure point.

Summary Table:

| Limitation | Description | Mitigation Strategy |

|---|---|---|

| Poor Thermal Shock Resistance | Susceptible to cracking from rapid temperature changes | Implement controlled heating and cooling cycles |

| Brittleness | Low tolerance for mechanical impacts and stress | Handle with care, avoid vibration and torsion |

| Risk of Leaks | Can lead to seal failures in high-vacuum or pressure systems | Ensure proper installation and gradual thermal ramps |

Need a high-temperature furnace solution tailored to your lab's unique challenges? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. With strong deep customization capabilities, we can design solutions that precisely meet your experimental needs, helping you overcome material limitations like brittleness and thermal shock. Contact us today to enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions