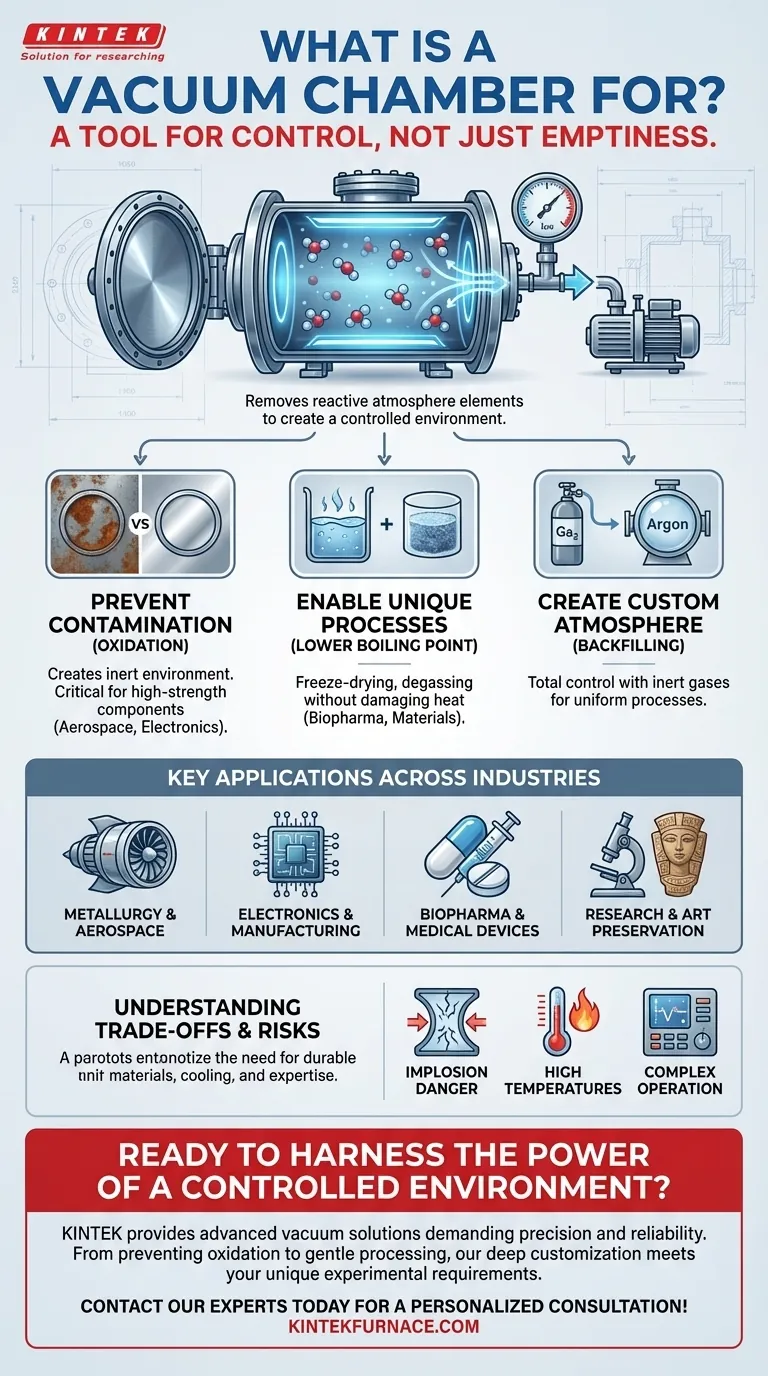

At its core, a vacuum chamber is a tool for control. It is a rigid enclosure from which air and other gases are removed to create an environment fundamentally different from the atmosphere around us. This controlled space is essential for a vast range of industrial, scientific, and medical processes where the presence of air would cause contamination, interference, or other undesirable chemical reactions.

The primary purpose of a vacuum chamber is not to create "emptiness," but to remove the reactive and unpredictable elements of our atmosphere. This allows for processes that require extreme purity, controlled pressure, or the manipulation of physical properties like boiling points.

The Core Principle: Why Remove the Air?

Understanding the function of a vacuum chamber comes down to understanding what happens when you remove the atmosphere. The air we breathe is a mixture of gases—primarily nitrogen and oxygen—that actively interacts with materials, especially at high temperatures.

To Prevent Chemical Contamination

The most common reason to use a vacuum is to prevent oxidation and other forms of contamination. When metals are heated to high temperatures for processes like brazing or sintering, the oxygen in the air will rapidly react with their surfaces, compromising their strength and integrity.

By removing the air, a vacuum chamber creates an inert environment. This is critical in aerospace for treating high-strength jet engine components and in electronics for creating clean, reliable circuits. The process ensures the material's properties remain pure.

To Enable Unique Physical Processes

A vacuum dramatically alters physical rules. By lowering the ambient pressure, you also lower the boiling point of liquids.

This principle is used in the biopharmaceutical industry for freeze-drying, where moisture is removed from sensitive medications without using damaging heat. It is also used for degassing, a process that pulls trapped air bubbles out of liquids and epoxies, improving their structural integrity.

To Create a Custom Atmosphere

Sometimes the goal isn't a pure vacuum but a perfectly controlled atmosphere. A chamber can be evacuated and then backfilled with a specific, non-reactive gas like argon.

This gives operators total control over the environment, preventing unwanted reactions while using an inert gas to assist with processes like uniform heat transfer.

Key Applications Across Industries

The ability to control a material's environment makes vacuum technology indispensable in many high-stakes fields.

Metallurgy and Aerospace

In this sector, vacuum furnaces are standard. They are used for heat-treating, sintering, and brazing high-performance metal alloys used in structural components and jet engines. The vacuum prevents the formation of surface oxides, ensuring maximum material strength.

Electronics and Manufacturing

Creating clean, durable parts is paramount. Vacuum chambers are used for metal injection molding and producing sintered components with high precision. This ensures that electronic parts are free of contaminants that could cause failures.

Biopharmaceuticals and Medical Devices

The medical field relies on vacuums for processes that demand purity and gentle handling. This includes sterilizing surgical instruments, drying delicate medications, and shaping medical-grade metals and plastics without introducing impurities.

Research and Art Preservation

In scientific research, vacuum chambers provide a stable, repeatable environment for experiments. In art conservation, they can be used to protect priceless artifacts or as part of a process to create protective, heat-treated enclosures.

Understanding the Trade-offs and Risks

While powerful, vacuum chambers are complex systems with inherent risks that demand expert knowledge and careful operation.

The Danger of Implosion

A high vacuum creates an immense pressure differential—the full force of the atmosphere is pressing on every square inch of the chamber's exterior. A structural flaw, a damaged seal, or improper use can lead to a catastrophic implosion.

Chambers must be built from durable materials like stainless steel and engineered to withstand this constant external force, especially when thermal stress is also a factor.

The Challenge of High Temperatures

Combining a vacuum with extreme heat (upwards of 1000°C) presents a significant engineering challenge. The material of the chamber must not only withstand the external atmospheric pressure but also the intense thermal stress.

Many high-temperature chambers include integrated cooling channels to manage the thermal load and prevent the chamber walls from failing. Attempting to heat a chamber not rated for it is extremely dangerous.

The Complexity of Operation

Achieving and maintaining a vacuum requires a system of components. This includes one or more vacuum pumps to remove the air, pressure gauges to monitor the level of vacuum, and sophisticated controllers to manage the process. Operating this equipment safely and effectively requires specialized training.

Making the Right Choice for Your Goal

The application of a vacuum chamber is determined entirely by the problem you need to solve.

- If your primary focus is material purity and high-temperature processing: The key is using a vacuum to prevent oxidation and contamination, which is essential for creating strong, reliable parts in aerospace and electronics.

- If your primary focus is gentle processing of sensitive materials: The key is using a vacuum to lower boiling points for drying or degassing without the damage that high heat would cause, which is vital in biopharmaceuticals.

- If your primary focus is research and experimentation: The key is using a vacuum to create a precisely controlled and repeatable environment that is completely isolated from unpredictable atmospheric variables.

Ultimately, a vacuum chamber is one of the most powerful tools for mastering a material's environment.

Summary Table:

| Key Function | Primary Benefit | Common Applications |

|---|---|---|

| Prevent Contamination | Creates an inert environment, preventing oxidation | High-temperature metal processing (Brazing, Sintering) |

| Enable Unique Processes | Lowers boiling points for gentle material handling | Freeze-drying, Degassing |

| Create Custom Atmospheres | Allows backfilling with specific gases for precise control | Uniform heat treatment, Research experiments |

Ready to harness the power of a controlled environment for your lab?

At KINTEK, we understand that your research and production goals demand precision and reliability. Whether you need to prevent oxidation in high-temperature sintering, gently process sensitive pharmaceuticals, or create a perfectly repeatable experimental atmosphere, the right vacuum chamber is critical.

Leveraging our exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace and vacuum solutions. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let's discuss how a KINTEK vacuum solution can enhance your process control and material outcomes. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- How does automation enhance the hot pressing process? Boost Precision, Efficiency, and Quality

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- What are the typical operational steps when using a vacuum press? Master Flawless Bonding and Forming

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies