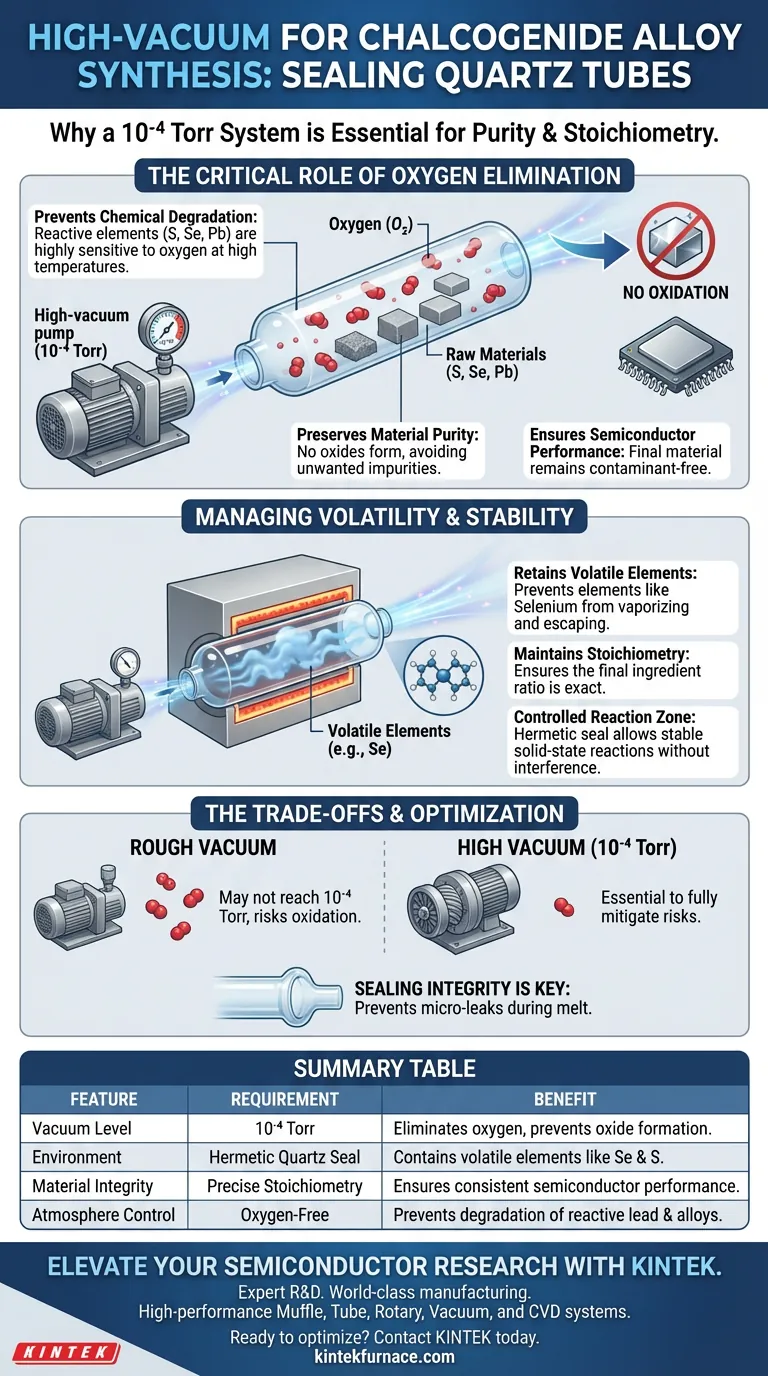

A high-vacuum system is essential for sealing quartz tubes to facilitate the complete removal of oxygen from the reaction environment, typically achieving a pressure level of $10^{-4}$ Torr. This evacuation is critical to prevent the oxidation of reactive components like sulfur, selenium, and lead during the high-temperature melting process.

By eliminating oxygen and encapsulating volatile components, the high-vacuum seal guarantees the chemical purity and precise stoichiometry required for the chalcogenide material to function as a semiconductor.

The Critical Role of Oxygen Elimination

Preventing Chemical Degradation

Chalcogenide alloys are composed of elements such as sulfur, selenium, and lead. These materials are highly sensitive to oxygen, especially when subjected to the high temperatures required for melting.

Preserving Material Purity

If oxygen is present in the tube, it reacts immediately with the raw materials to form oxides. This chemical reaction introduces unwanted impurities that fundamentally alter the physical characteristics of the final alloy.

Ensuring Semiconductor Performance

For the material to function correctly as a semiconductor, it must remain free of these oxide contaminants. A high-vacuum system reaching $10^{-4}$ Torr ensures that the environment is sufficiently void of oxygen to prevent these damaging reactions.

Managing Volatility and Stability

Retaining Volatile Elements

Beyond oxidation, the melting process poses a risk to volatile components like Selenium. At high temperatures, these elements can easily vaporize and escape the mixture.

Maintaining Stoichiometry

The vacuum-sealed environment acts as a containment system. It prevents the loss of volatile elements, ensuring the final ratio of ingredients (stoichiometry) remains exactly as intended.

Creating a Controlled Reaction Zone

The sealed quartz tube provides a stable, isolated environment. This allows solid-state reactions to proceed in a controlled manner without interference from the outside atmosphere or fluctuating pressures.

Understanding the Trade-offs

The Necessity of High Vacuum

It is important to distinguish between a rough vacuum and the high vacuum required here. A simple roughing pump may not reach the $10^{-4}$ Torr threshold necessary to fully mitigate oxidation risks.

Sealing Integrity

Achieving the vacuum is only half the battle; maintaining it is the other. If the quartz tube is not sealed perfectly after evacuation, micro-leaks will reintroduce oxygen during the melt, rendering the vacuum step useless.

Optimizing Your Sealing Process

If your primary focus is Material Purity:

- Ensure your pumping system can consistently achieve and hold a vacuum level of $10^{-4}$ Torr to completely rule out oxidation.

If your primary focus is Composition Control:

- Rely on the physical integrity of the quartz seal to encapsulate volatile elements like Selenium, preventing mass loss during heating.

The high-vacuum seal is not merely a preparatory step; it is the fundamental guarantor of your alloy's chemical identity and functional performance.

Summary Table:

| Feature | Requirement | Benefit |

|---|---|---|

| Vacuum Level | $10^{-4}$ Torr | Eliminates oxygen to prevent oxide formation |

| Environment | Hermetic Quartz Seal | Contains volatile elements like Selenium and Sulfur |

| Material Integrity | Precise Stoichiometry | Ensures consistent semiconductor performance |

| Atmosphere Control | Oxygen-Free | Prevents chemical degradation of reactive lead and alloys |

Elevate Your Semiconductor Research with KINTEK

Precise material synthesis starts with the right environment. At KINTEK, we understand the rigorous demands of high-vacuum processing. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for your laboratory's success.

Whether you are sealing quartz tubes for chalcogenide alloys or developing next-generation materials, our customizable high-temperature furnaces ensure the chemical purity and thermal stability your project requires.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your unique needs.

Visual Guide

References

- Mohamed Muthana Ghazi, Kareem A. Jasim. An investigation into the implications of partial substitution of selenium with lead on the thermal properties for S<sub>60</sub>Se<sub>40-X</sub>Pb<sub>X</sub> Chalcogenide Compound. DOI: 10.1088/1742-6596/2857/1/012007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a sintering process using a lab furnace necessary for Li6PS5Cl disks? Enhance Conductivity & Density

- What is the function of a vacuum drying oven for biochar FTIR analysis? Ensure High-Purity Sample Preparation

- Why are alumina (Al2O3) sample pans or crucibles essential for DSC testing of titanium alloys? Expert Insights

- What is the maximum pressure achievable by the circulating water vacuum pump? Discover Its Vacuum Limits

- What types of trays are compatible with SiC heating elements? Choose Graphite or Composite Ceramics for Thermal Shock Resistance

- What are the primary functions of the vacuum pump system and inert gases? Achieve High-Purity Atomization

- What is the significance of using a laboratory electric thermostatic blast drying oven for biomass briquette moisture control?

- What role do quartz tubes play in semiconductor manufacturing? Essential for Purity and High-Temp Processes