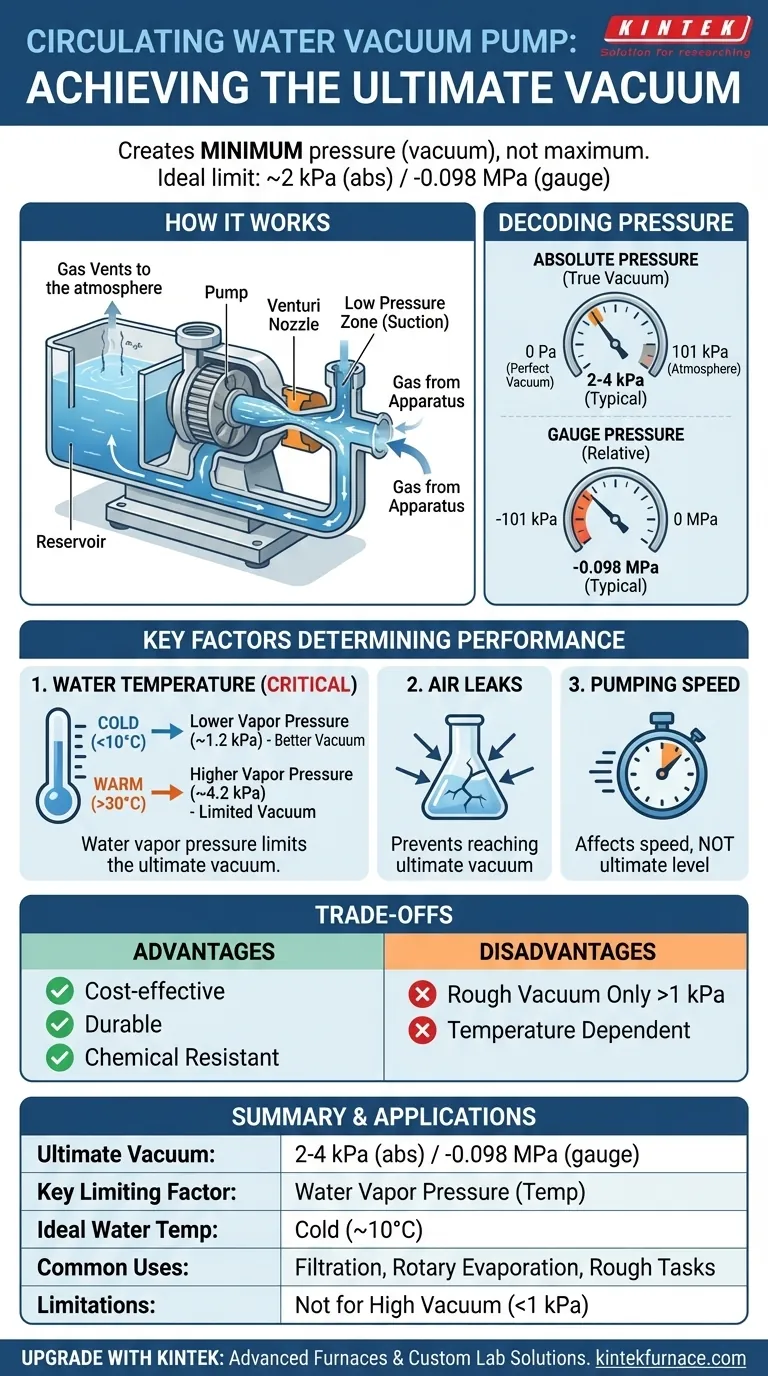

The short answer is that a circulating water vacuum pump doesn't create "maximum pressure" but rather a minimum pressure, or vacuum. A high-performance model can achieve an ultimate vacuum level of approximately 2 kPa (kilopascals), which is often expressed as a gauge pressure of -0.098 MPa relative to the atmosphere.

The ultimate vacuum a water-based pump can achieve is fundamentally limited by the vapor pressure of the water itself. While specifications may list an ideal vacuum of 2 kPa, real-world performance is dictated almost entirely by the temperature of the circulating water.

How a Circulating Water Vacuum Pump Works

The Venturi Principle

A circulating water vacuum pump operates on a simple, robust principle. It uses an internal pump to move a stream of water from a reservoir through a specially shaped nozzle called a venturi or ejector.

As water is forced through the narrowest part of the venturi, its velocity increases dramatically, causing a sharp drop in pressure according to Bernoulli's principle. This low-pressure zone creates suction, pulling gas from the connected apparatus into the water stream.

Gas Removal

The entrained gas is then carried along with the water into the reservoir. As the water returns to the larger, lower-velocity environment of the tank, the gas separates and is vented to the atmosphere, while the water is recirculated to repeat the cycle.

Decoding Vacuum Pressure Specifications

The numbers used to describe a vacuum can be confusing. The performance of these pumps is typically described using two different measurements: absolute pressure and gauge pressure.

Absolute Pressure (The True Vacuum)

Absolute pressure is measured relative to a perfect vacuum (0 Pa). This is the most accurate way to define the level of vacuum. For this measurement, a lower number is better, indicating less gas and a deeper vacuum.

A typical high-quality circulating water pump is rated for an ultimate vacuum of 2 kPa to 4 kPa (20 to 40 mbar).

Gauge Pressure (Pressure Below Atmosphere)

Gauge pressure measures pressure relative to the surrounding atmospheric pressure (approx. 101 kPa at sea level). Since a vacuum is a pressure below atmospheric, it is expressed as a negative value.

You will often see a specification like -0.098 MPa. This simply means the pump can reduce the pressure to 0.098 MPa below the current atmospheric pressure. This corresponds to an absolute pressure of around 2-3 kPa.

Key Factors That Determine Actual Performance

The advertised vacuum level is an ideal figure. In practice, the performance you achieve is governed by several critical factors.

The Critical Role of Water Temperature

This is the single most important variable. The ultimate vacuum of the pump is physically limited by the vapor pressure of the water being used as the working fluid.

Water itself will begin to boil and turn into vapor at low pressures. The pump cannot create a vacuum deeper than the vapor pressure of the water in its own reservoir.

- Cold Water (e.g., 10°C / 50°F): Has a low vapor pressure (~1.2 kPa). The pump can get close to its theoretical maximum vacuum.

- Warm Water (e.g., 30°C / 86°F): Has a much higher vapor pressure (~4.2 kPa). The pump will be unable to achieve a vacuum deeper than this, regardless of its specifications.

Air Leaks in the System

Even a microscopic leak in your glassware, tubing, or seals will allow atmospheric air to enter the system. The pump must work constantly to remove this incoming air, which will prevent it from reaching its ultimate vacuum level.

Pumping Speed (Flow Rate)

A pump's speed (e.g., 80 L/min) refers to the volume of gas it can move over time. A higher speed allows the pump to evacuate a large container more quickly and helps it overcome small leaks more effectively. However, pumping speed does not affect the ultimate vacuum level the pump can achieve in a perfectly sealed system.

Understanding the Trade-offs

Advantage: Cost and Durability

These pumps are mechanically simple, making them relatively inexpensive, quiet, and resistant to corrosive vapors that would damage more complex pumps.

Disadvantage: Moderate Vacuum Level

A circulating water pump provides a rough vacuum. It is unsuitable for applications requiring high vacuum levels (below ~1 kPa), such as mass spectrometry or electron microscopy.

Disadvantage: Water Management

The performance is entirely dependent on water temperature, which can rise during operation. Furthermore, the water can absorb vapors from the experiment, which may require periodic changing to maintain performance and prevent contamination.

Making the Right Choice for Your Application

Use these guidelines to determine if this technology fits your needs.

- If your primary focus is routine lab work like filtration or rotary evaporation of common solvents: A circulating water vacuum pump is a highly cost-effective and reliable choice.

- If your primary focus is achieving a high vacuum (<1 kPa) for sensitive processes: You must use a different technology, such as a multi-stage diaphragm pump or an oil-sealed rotary vane pump.

- If your primary focus is maximizing performance from your water pump: Use the coldest water possible, ensure your system is perfectly sealed, and consider adding an atmospheric ejector to achieve pressures below 1 kPa.

Ultimately, selecting the right vacuum pump means matching its capabilities to the precise pressure requirements of your process.

Summary Table:

| Aspect | Details |

|---|---|

| Ultimate Vacuum | 2-4 kPa (absolute pressure) or -0.098 MPa (gauge pressure) |

| Key Limiting Factor | Vapor pressure of water, dependent on temperature |

| Ideal Water Temperature | Cold water (e.g., 10°C) for lower vapor pressure (~1.2 kPa) |

| Common Applications | Filtration, rotary evaporation, rough vacuum tasks |

| Limitations | Unsuitable for high vacuum (<1 kPa); requires sealed systems |

Upgrade your laboratory's vacuum capabilities with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for efficient and reliable processes. Contact us today to discuss how our products can enhance your lab's performance and achieve superior results!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a laboratory vacuum drying oven necessary for processing nano MOFs? Preserve nLn-bdc Structural Integrity

- Why use graphite crucibles for sludge ash reduction? Unlock Superior Reduction & Heat Resistance

- What are the advantages of using a Type B thermocouple for 1600°C slag reduction? Precision in Ultra-High Heat

- How does a PID temperature controller facilitate gasification research? Unlock Precision in Industrial Simulations

- Why is the vacuum sealing of quartz tubes essential? Secure PdSe2 Growth and High-Temperature Safety

- Why is a heat-resistant crucible indispensable for magnesium purification? Ensuring Purity and Efficiency in Vacuum Sublimation

- What is the function of a graphite crucible in iron ore softening tests? Simulate Blast Furnace Conditions Perfectly

- What is the function of a high alumina crucible in chloride salt purification? Protect Purity and Thermal Stability