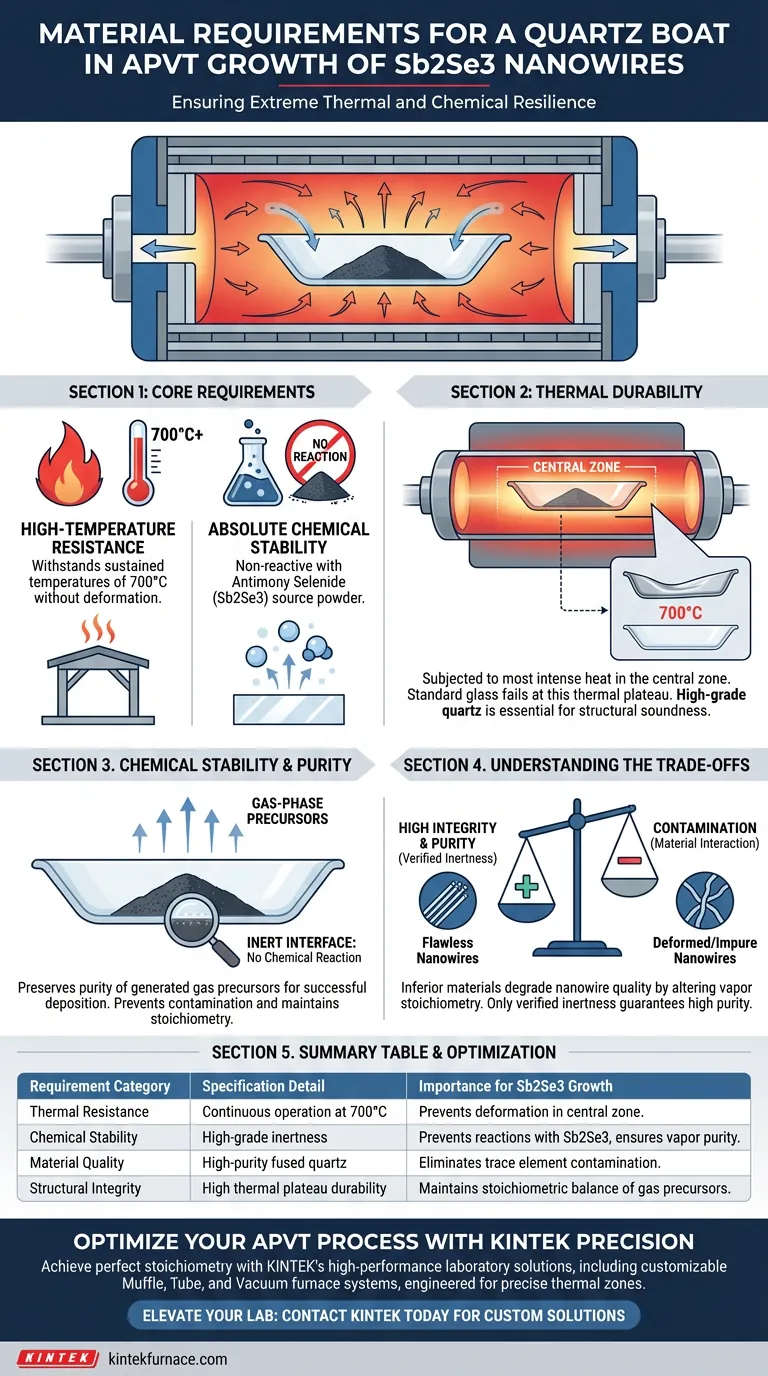

The material requirements for a quartz boat used in Atmospheric Pressure Vapor Transport (APVT) are defined by the need for extreme thermal and chemical resilience. To successfully grow Antimony Selenide (Sb2Se3) nanowires, the carrier must possess high-temperature resistance capable of withstanding 700°C and absolute chemical stability to prevent any reaction with the source powder.

In the context of APVT growth, the quartz boat acts as a non-reactive vessel; its primary function is to hold the source material in the furnace's central zone without compromising the purity of the resulting gas-phase precursors.

Thermal Durability Requirements

Withstanding the Central Zone

The quartz boat is subjected to the most intense conditions within the furnace. It is positioned directly in the central zone, where the heat is concentrated.

Operating Temperature Thresholds

The material must remain structurally sound at sustained temperatures reaching 700 degrees Celsius. At this specific thermal plateau, standard glass would fail, making high-grade quartz essential for the process.

Chemical Stability and Purity

Inertness with Source Material

The boat carries high-purity Antimony Selenide (Sb2Se3) powder. It is a critical requirement that the quartz surface does not chemically react with this powder, even when heated to the sublimation point.

Preserving Gas-Phase Purity

Any reaction between the boat and the source material introduces contaminants. High chemical stability ensures that the gas-phase precursors generated during heating remain pure throughout the deposition process.

Understanding the Trade-offs

The Cost of Material Interaction

If the quartz boat lacks sufficient chemical stability, it will degrade the quality of the nanowires. A reaction at the interface between the boat and the Sb2Se3 powder alters the stoichiometry of the vapor.

Integrity vs. Contamination

While a standard boat might physically hold the powder, only one with verified inertness guarantees the high level of purity required for successful nanowire growth. Using inferior materials risks contaminating the entire batch of nanowires.

Ensuring Successful Nanowire Growth

To apply these requirements to your specific APVT setup, consider your primary objectives:

- If your primary focus is Purity: Prioritize a quartz boat certified for high chemical stability to ensure zero reaction with the Sb2Se3 powder.

- If your primary focus is Process Stability: Ensure the boat is rated for continuous operation at or above 700°C to prevent deformation in the central zone.

Selecting the correct carrier is the foundational step in maintaining the integrity of the deposition environment.

Summary Table:

| Requirement Category | Specification Detail | Importance for Sb2Se3 Growth |

|---|---|---|

| Thermal Resistance | Continuous operation at 700°C | Prevents deformation in the furnace central zone. |

| Chemical Stability | High-grade inertness | Prevents reactions with Sb2Se3 powder to ensure vapor purity. |

| Material Quality | High-purity fused quartz | Eliminates risk of trace element contamination in nanowires. |

| Structural Integrity | High thermal plateau durability | Maintains stoichiometric balance of gas-phase precursors. |

Optimize Your APVT Process with KINTEK Precision

Achieving the perfect stoichiometry in Sb2Se3 nanowire growth requires equipment that never compromises on purity. KINTEK provides high-performance laboratory solutions backed by expert R&D and manufacturing. Our customizable Muffle, Tube, and Vacuum furnace systems are engineered to maintain the precise thermal zones your research demands.

Whether you need standard components or specialized high-temperature systems, we deliver the reliability required for advanced material synthesis.

Ready to elevate your lab's capabilities? Contact KINTEK today to discuss your unique technical requirements and custom solutions.

Visual Guide

References

- Atmospheric Pressure Vapor Transport Deposition of Sb<sub>2</sub>Se<sub>3</sub> Nanowires and Their Application in Photodetection. DOI: 10.1002/admt.202500722

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the functions of alumina crucibles and quartz sleeve encapsulation in the synthesis of calcium perrhenates?

- What are the advantages of using a Boron Nitride crucible? Maximize Purity and Efficiency in Laser Pyrolysis

- How do alumina ceramic furnace tubes compare to other materials like quartz or silicon carbide? Choose the Best for Your High-Temp Needs

- What other industrial applications do graphite crucible furnaces have beyond metal melting? Unlock Advanced Material Processing

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What is the main purpose of BN coating on graphite in Ti-6Al-4V hot pressing? Ensure Purity & Easy Release

- What is the function of a graphite crucible during the synthesis of LaMg6Ga6S16 crystals? Ensure Purity & Protection

- What is the role of quartz capillaries in the vacuum sealing process of sulfur? Enhance Purity and In-Situ Analysis