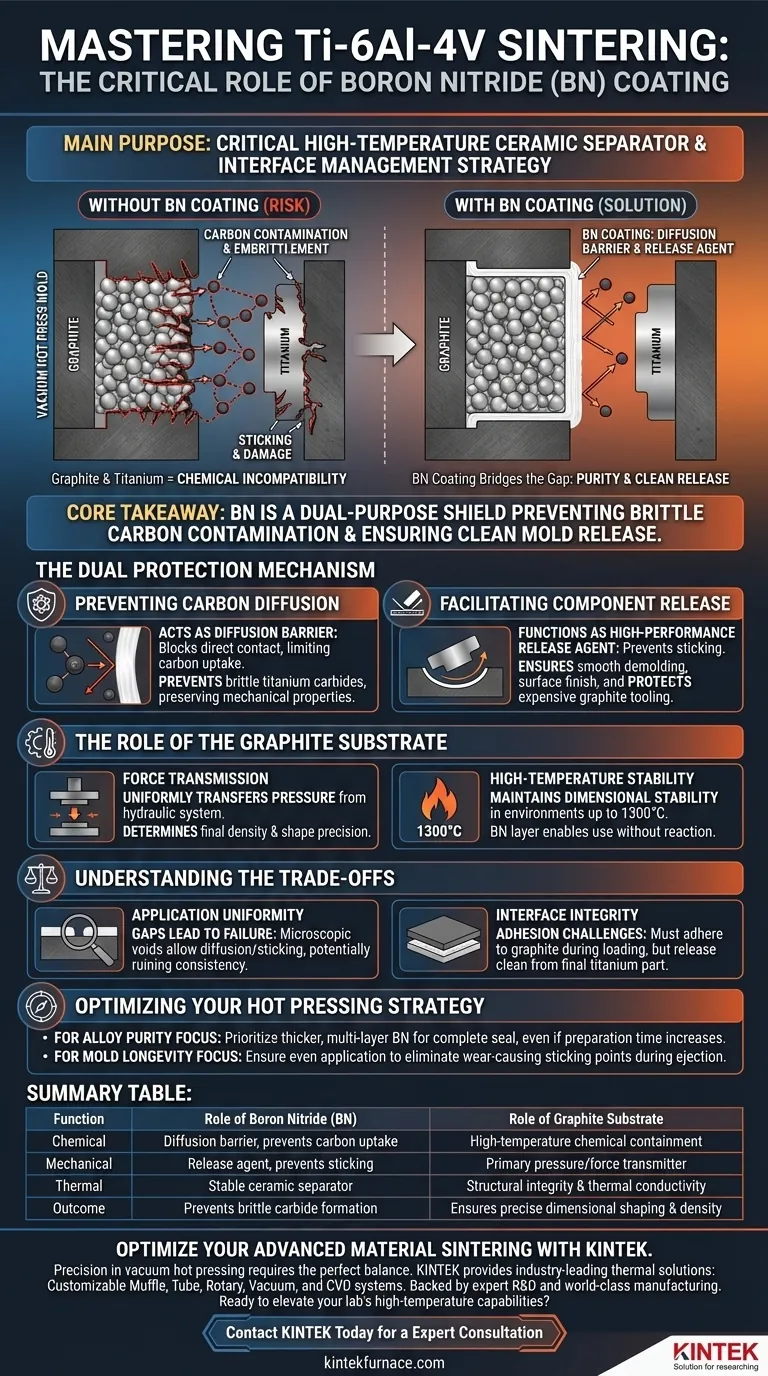

The application of a Boron Nitride (BN) coating acts as a critical interface management strategy during the vacuum hot pressing of Ti-6Al-4V alloys. Its main function is to serve as a high-temperature ceramic separator that physically isolates the reactive titanium powder from the carbon-based graphite tooling.

Core Takeaway While graphite provides the necessary structural integrity for hot pressing, it is chemically incompatible with titanium at high temperatures. The BN coating bridges this gap, serving as a dual-purpose shield that prevents brittle carbon contamination in the alloy and ensures the finished part releases cleanly from the mold.

The Dual Protection Mechanism

Preventing Carbon Diffusion

Titanium alloys like Ti-6Al-4V are highly reactive at sintering temperatures. If left unprotected, carbon atoms from the graphite mold will diffuse into the titanium powder.

The BN coating acts as a diffusion barrier. By blocking direct contact between the powder and the tooling, it significantly limits carbon uptake. This is essential for preventing the formation of titanium carbides, which can embrittle the alloy and degrade its mechanical properties.

Facilitating Component Release

Under the immense heat and pressure of vacuum hot pressing, metals naturally tend to adhere to their containment vessels.

BN functions as a high-performance release agent. It prevents the titanium sample from sticking to the mold walls. This ensures smooth demolding, preserving the surface finish of the sample and protecting the expensive graphite mold from damage during extraction.

The Role of the Graphite Substrate

Force Transmission

While the BN coating handles the surface chemistry, the graphite mold underneath handles the mechanics.

Graphite serves as the force transmitter. It uniformly transfers pressure from the hydraulic system to the powder body. This uniform pressure is what determines the final density and shape precision of the sample.

High-Temperature Stability

Graphite acts as the forming container, maintaining dimensional stability in environments up to 1300°C.

The coating complements this stability. While graphite offers excellent thermal conductivity and strength, the BN layer ensures these properties can be utilized without triggering severe interface reactions with the metal payload.

Understanding the Trade-offs

Application Uniformity

The effectiveness of the barrier is entirely dependent on coverage.

Gaps lead to localized failure. Even a microscopic void in the BN coating can allow carbon diffusion or sticking at that specific point, potentially ruining the part's consistency.

Interface Integrity

The coating is an additional material variable in the process.

Adhesion challenges. The BN coating must adhere well enough to the graphite to stay in place during loading, but not so strongly to the titanium that it becomes difficult to clean off the final part.

Optimizing Your Hot Pressing Strategy

To get the most out of your vacuum hot pressing process, tailor your coating application to your specific priorities.

- If your primary focus is Alloy Purity: Prioritize a thicker, multi-layer BN application to guarantee a complete seal against carbon diffusion, even if it slightly increases mold preparation time.

- If your primary focus is Mold Longevity: Ensure the coating is applied evenly to all contact surfaces to eliminate sticking points that cause wear and tear on the graphite tooling during ejection.

The BN coating is not just an accessory; it is the essential enabler that allows reactive titanium to be processed within cost-effective graphite tooling.

Summary Table:

| Function | Role of Boron Nitride (BN) | Role of Graphite Substrate |

|---|---|---|

| Chemical | Acts as a diffusion barrier to prevent carbon uptake | Provides high-temperature chemical containment |

| Mechanical | Functions as a release agent to prevent sticking | Serves as the primary pressure/force transmitter |

| Thermal | Remains stable as a ceramic separator | Offers structural integrity and thermal conductivity |

| Outcome | Prevents brittle carbide formation | Ensures precise dimensional shaping and density |

Optimize Your Advanced Material Sintering with KINTEK

Precision in vacuum hot pressing requires the perfect balance of chemical protection and mechanical strength. KINTEK provides industry-leading thermal solutions, including customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to handle the rigorous demands of reactive alloy processing.

Backed by our expert R&D and world-class manufacturing, we help labs and industrial facilities achieve superior material purity and mold longevity. Whether you are processing Ti-6Al-4V or developing next-generation ceramics, our equipment is built to meet your unique specifications.

Ready to elevate your lab's high-temperature capabilities?

Contact KINTEK Today for a Expert Consultation

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is the use of high-vacuum pump groups critical for photothermal catalytic chamber pre-treatment?

- What role does a mechanical vacuum pump system play in cerium dioxide reduction? Boost Efficiency at Lower Pressures

- What is the function of a forced air drying oven in zeolite preparation? Protect Pore Integrity and Ensure Uniformity

- What are the advantages of using high-purity alumina crucibles? Achieve Precise Cast Iron Phase Equilibrium Data

- What is the technical significance of using a quartz boat in 2D superlattice preparation? Enhancing CVD Precision

- What are the common uses for Alumina ceramic tubes? Ideal for High-Temp, Insulation, and Corrosion Resistance

- Why must the reaction containers be sealed within a fused quartz tube? Protect Your Crystal Growth Integrity

- Can alumina ceramic furnace tubes be customized for specific applications? Enhance Your High-Temperature Processes