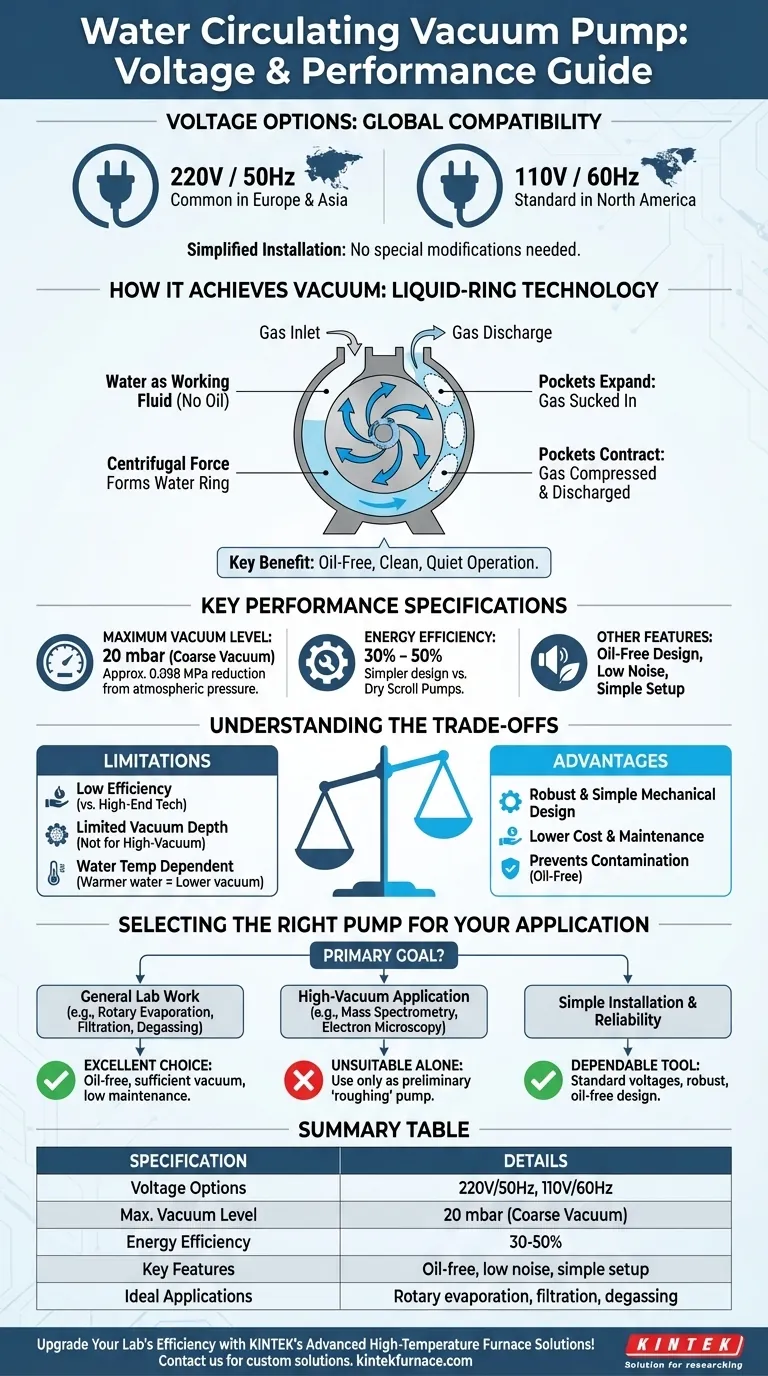

In short, the water circulating vacuum pump is available in two standard voltage configurations: 220V/50Hz and 110V/60Hz. These options are designed to align with the common electrical standards found in different regions, ensuring broad compatibility for laboratory and industrial use without the need for special electrical modifications.

The availability of standard voltages makes this pump easy to install, but the more critical decision is whether its performance—specifically its moderate vacuum level and efficiency—aligns with your specific application.

How This Pump Achieves a Vacuum

Understanding how this pump works is key to appreciating its benefits and limitations. Unlike oil-based pumps, it uses a simple and clean mechanical process.

The Role of Circulating Water

This pump is a type of liquid-ring pump that uses water as its working fluid. The water is not just for cooling; it is the essential component that creates the vacuum. This design is the reason for its key characteristics: no oil, no oil-related pollution, and quiet operation.

Creating Negative Pressure

As the internal impeller spins, centrifugal force throws the water against the outer wall of the pump's chamber, forming a stable ring. Because the impeller is mounted off-center, small pockets of space are created between the impeller blades and the inner surface of the water ring.

As the blades rotate, these pockets first expand in volume, sucking gas in from the inlet port. Continuing their rotation, the pockets then contract, compressing the gas and forcing it out through the discharge port. This continuous cycle of expansion and contraction is what generates a steady, reliable vacuum.

Key Performance Specifications

Beyond voltage, several technical specifications determine if this pump is the right fit for your task.

Available Voltage Options

The pump is offered in 220V/50Hz, common in Europe and Asia, and 110V/60Hz, the standard in North America. This dual-voltage availability simplifies procurement and installation.

Maximum Vacuum Level

The pump can achieve a maximum vacuum level of 20 mbar (equivalent to reducing the pressure by approximately 0.098 MPa from atmospheric pressure). This is considered a coarse or rough vacuum, suitable for many common lab procedures.

Other Notable Features

The design is inherently oil-free, which prevents contamination of your process and eliminates the need for oil changes. It is also characterized by low noise and a simple, flexible setup.

Understanding the Trade-offs

While effective, this pump's design comes with inherent trade-offs that are critical to consider.

Efficiency Considerations

The typical energy efficiency of this type of pump is around 30%, with higher-end models reaching up to 50%. This is relatively low compared to other vacuum technologies like dry scroll pumps. The trade-off is for a simpler, often more robust, and lower-cost mechanical design.

Limitations on Vacuum Depth

A vacuum level of 20 mbar is not suitable for high-vacuum applications. Processes like mass spectrometry, electron microscopy, or semiconductor manufacturing require much deeper vacuums (lower pressures). This pump is ideal for applications like filtration, degassing, and rotary evaporation.

Dependence on Water Temperature

The pump's ultimate vacuum is limited by the vapor pressure of the water being used. Warmer water has a higher vapor pressure, which means it will begin to boil at a higher pressure, preventing the pump from reaching its maximum vacuum depth. For best performance, use cool circulating water.

Selecting the Right Pump for Your Application

Use these guidelines to determine if this pump matches your primary goal.

- If your primary focus is general lab work like rotary evaporation or filtration: This pump is an excellent, low-maintenance choice due to its oil-free operation and sufficient vacuum level.

- If your primary focus is a high-vacuum application: This pump is unsuitable on its own and should only be considered as a preliminary "roughing" pump for a more advanced high-vacuum system.

- If your primary focus is simple installation and reliability: The standard voltage options and robust, oil-free design make it a straightforward and dependable tool for compatible applications.

Understanding these core characteristics ensures you are selecting a tool that truly fits your operational needs.

Summary Table:

| Specification | Details |

|---|---|

| Voltage Options | 220V/50Hz, 110V/60Hz |

| Maximum Vacuum Level | 20 mbar (coarse vacuum) |

| Energy Efficiency | 30-50% |

| Key Features | Oil-free, low noise, simple setup |

| Ideal Applications | Rotary evaporation, filtration, degassing |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your processes and deliver tailored solutions for your needs!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a high-purity quartz tube play in flash Joule heating? Ensure Safety and Process Control

- What is the purpose of using quartz vacuum encapsulation? Optimize La(Fe,Si)13-based Magnetocaloric Alloys

- Why use alumina crucibles for NaNbO3:Pr3+ annealing? Ensure High Purity and Thermal Stability

- What characteristics are required for reaction vessels in PI-COFs synthesis? Ensure High-Pressure Safety and Purity

- What role does a laboratory oven play in the evaluation of the physical properties of teak activated carbon? Accuracy Tips

- What is the function of a laboratory electric blast drying oven in biomass pretreatment? Standardize Your Samples

- Why is a high-performance vacuum pump system essential for magnesium purification? Achieve High Purity and Efficiency

- What type of pump is used in water circulating vacuum pumps and how is it installed? Discover Robust Fluid-Based Vacuum Solutions