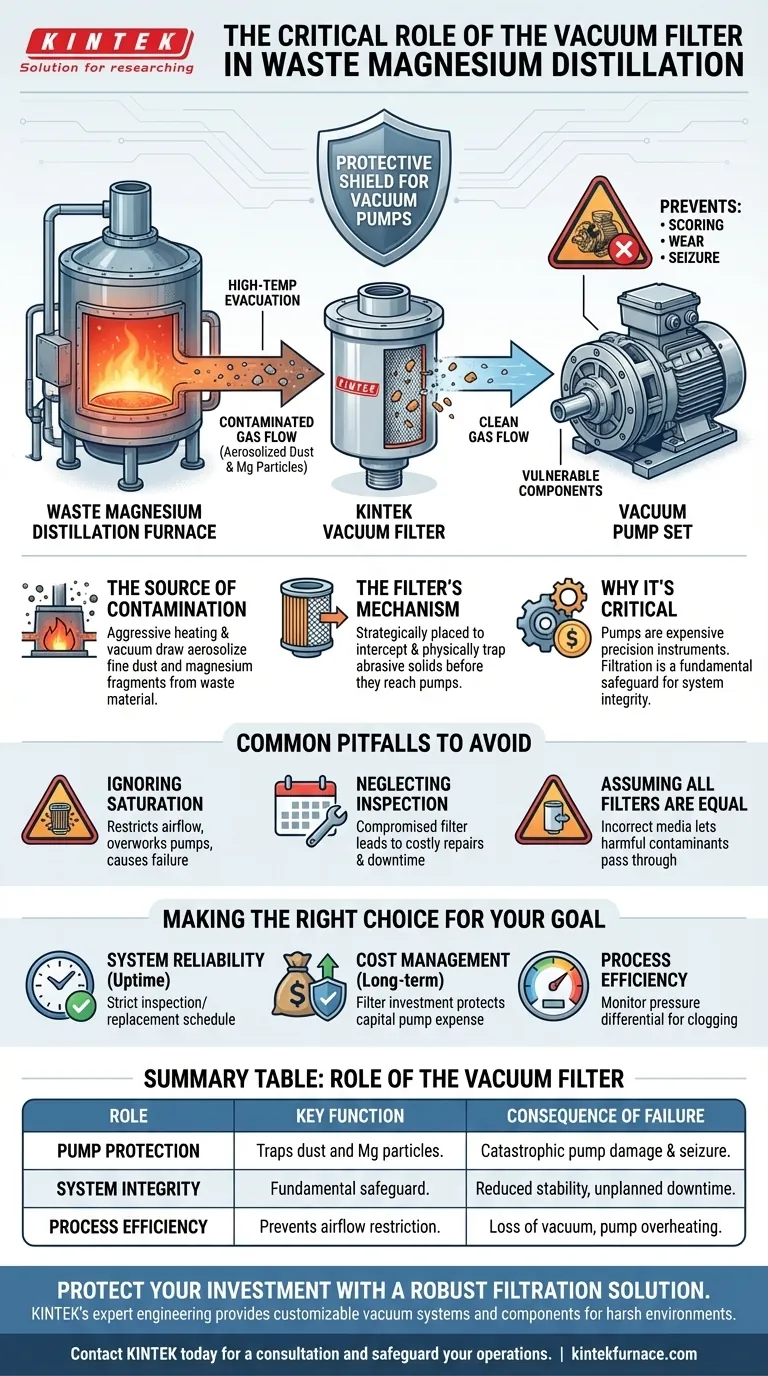

At its core, the vacuum filter in a waste magnesium distillation system serves one critical role: to act as a protective shield for the vacuum pumps. During the high-temperature evacuation process, gas flow inevitably carries fine dust and magnesium particles from the raw material, and the filter is specifically designed to trap these contaminants before they can cause catastrophic damage.

The vacuum filter is not an optional accessory but a fundamental safeguard. Its function is to prevent particle contamination, directly ensuring the mechanical integrity, operational stability, and long-term reliability of the entire vacuum system.

The Source of Contamination

To understand the filter's importance, you must first understand the environment it operates in. The distillation process itself is what creates the hazard the filter is designed to mitigate.

The Vacuum Distillation Process

A vacuum distillation furnace creates a high-temperature, low-pressure environment. Inside, hazardous magnesium waste is heated, causing the pure magnesium to turn into a vapor, leaving behind impurities like oxides, silicon, and other metals.

Generation of Particulates

This aggressive heating and the powerful draw of the vacuum pumps aerosolize fine particles. Dust and minuscule magnesium fragments from the source material become entrained in the gas flow moving toward the pumps.

The Filter's Protective Mechanism

The filter is strategically placed to intercept this contaminated gas flow before it reaches the most vulnerable components of the system.

Strategic Placement

The vacuum filter is always installed between the furnace body and the vacuum pump set. This positioning ensures that all gas evacuated from the furnace must pass through the filter media first.

Intercepting Harmful Debris

The filter contains media engineered to allow gas molecules to pass through unimpeded while physically trapping the solid, abrasive particles. This simple mechanical separation is the key to protecting the system.

Why This Protection is Critical

Vacuum pumps are precision instruments with extremely tight tolerances. The introduction of hard, abrasive particles like dust or metal fragments leads directly to scoring, increased wear, and eventual seizure of the pump's internal components.

Common Pitfalls to Avoid

Failing to properly manage the vacuum filter is one of the most common and costly mistakes in maintaining a distillation system.

Ignoring Filter Saturation

A filter has a finite capacity. Once it becomes clogged with particulates, it severely restricts airflow. This forces the vacuum pumps to work harder, reduces system efficiency, and can lead to pump overheating and premature failure.

Neglecting Regular Inspection

The filter is the system's first line of defense, but it cannot perform its job if it is compromised or saturated. A lack of routine inspection and replacement is a direct path to expensive pump repairs and unplanned downtime.

Assuming All Filters Are Equal

Using an incorrect or low-quality filter medium can provide a false sense of security. If the filter is not rated for the specific particle size generated by your process, harmful contaminants can pass right through it and into your pumps.

Making the Right Choice for Your Goal

Your operational priorities should directly inform how you approach filter management.

- If your primary focus is system reliability and uptime: Treat the vacuum filter as a mission-critical component and adhere to a strict inspection and replacement schedule based on operating hours.

- If your primary focus is long-term cost management: View the recurring cost of filter elements as a small, essential investment that protects the far greater capital expense of the vacuum pumps.

- If your primary focus is process efficiency: Monitor the pressure differential across the filter, as a sudden increase can signal a clogged filter and a loss of vacuum performance.

Ultimately, the vacuum filter is the single most important element ensuring the longevity of your system's most critical and expensive mechanical components.

Summary Table:

| Role of the Vacuum Filter | Key Function | Consequence of Failure |

|---|---|---|

| Pump Protection | Traps dust and magnesium particles from gas flow. | Catastrophic damage, scoring, and seizure of vacuum pumps. |

| System Integrity | Acts as a fundamental safeguard, not an accessory. | Reduced operational stability and unplanned downtime. |

| Process Efficiency | Prevents filter clogging from restricting airflow. | Loss of vacuum performance and pump overheating. |

Protect Your Investment with a Robust Filtration Solution

Your vacuum distillation system's reliability hinges on effective particle filtration. Abrasive contaminants can quickly lead to costly pump repairs and significant operational downtime.

KINTEK's expert engineering provides the robust protection your system needs. Backed by expert R&D and manufacturing, we offer customizable vacuum systems and components designed for harsh industrial environments like magnesium distillation. We understand the critical need to shield your pumps from particulate damage.

Ensure your system's longevity and efficiency. Let our team help you select or design the optimal filtration solution for your unique process requirements.

Contact KINTEL today for a consultation and safeguard your operations.

Visual Guide

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a high-vacuum pump system facilitate the synthesis of high-quality calcium-based perrhenates? Expert Synthesis

- What role do the exhaust branch pipes at the top of a vacuum chamber play? Optimize Your Pressure Control Today

- How do you maintain vacuum pressure? Master the Balance of Gas Load & Pumping Speed

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?

- What is the material of the anode in a vacuum tube? Choosing the Right Metal for Power & Performance