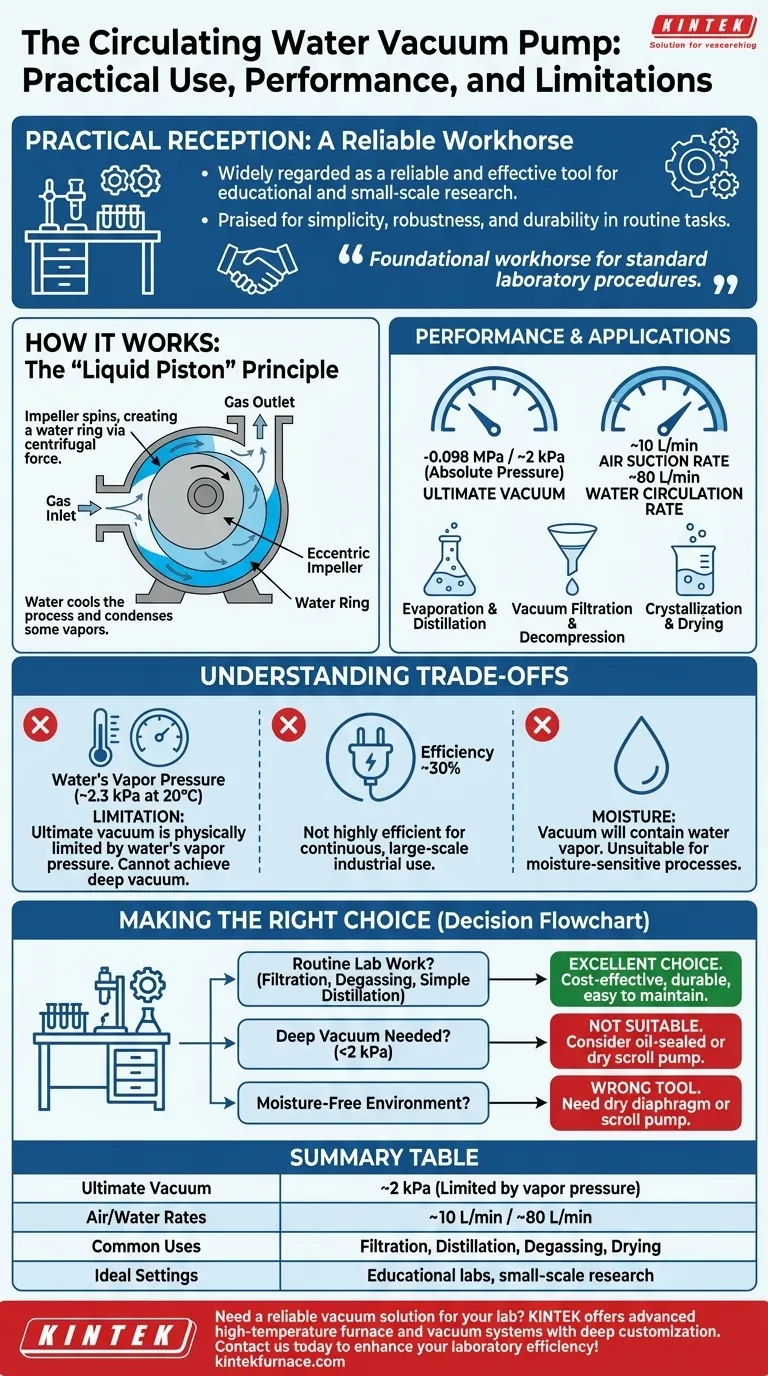

In practical use, the circulating water vacuum pump is widely regarded as a reliable and effective tool, particularly within educational and small-scale research settings. It has been successfully implemented in numerous chemical experiments for processes like filtration, distillation, and degassing, receiving positive feedback for its simplicity and robustness.

This pump is a foundational workhorse for standard laboratory procedures. Its value lies in its durability and ease of use, though its ultimate performance is inherently limited by the physical properties of water itself.

How a Circulating Water Vacuum Pump Works

To understand its practical reception, we must first understand its design. Unlike complex high-vacuum pumps, its principle is elegantly simple and mechanical.

The Core Principle: The "Liquid Piston"

The pump uses water as its working medium. Inside the pump casing, an off-center impeller spins, creating a ring of water along the outer wall due to centrifugal force.

Because the impeller is eccentric, the space between its blades and the water ring constantly changes. As the space expands, it draws in gas from the inlet; as it contracts, it compresses and expels the gas, creating a continuous vacuum effect. This action is often described as a series of radial "liquid pistons."

Why Water is the Working Fluid

Water is used because it is inexpensive, readily available, and effective at forming the necessary liquid ring. The pump is designed to work with water or other liquids that share similar chemical and physical properties.

This design also means the pump's operation helps cool the vacuum-generating process and can condense some vapors drawn from the experiment, which can be an advantage.

Practical Performance and Applications

The pump's design directly dictates its ideal use cases and performance ceiling. It is not a high-performance deep vacuum pump, but rather a general-purpose utility for common lab tasks.

Typical Performance Metrics

A representative model demonstrates the typical capabilities of this technology. It can achieve an ultimate vacuum of approximately -0.098 MPa (megapascals), which is equivalent to an absolute pressure of around 2 kPa (20 mbar).

Other key specs include a single-tap air suction rate of around 10 L/min and a water circulation rate of 80 L/min. These units are typically benchtop-sized and are built for continuous operation.

Common Laboratory Uses

This level of vacuum is perfectly suited for a wide range of common processes. It excels in applications like:

- Evaporation and Distillation

- Crystallization and Drying

- Sublimation

- Vacuum Filtration and Decompression

- Degassing liquids

Reception in Educational and Research Settings

The pump is exceptionally well-received in school and university laboratories. Its robust, simple-to-maintain design and the absence of pump oil make it a safe and cost-effective choice for teaching and routine research.

Understanding the Trade-offs

No single technology is perfect for every task. The circulating water vacuum pump has clear limitations that are critical to understand before selecting it for a project.

The Ultimate Vacuum Limitation: Water's Vapor Pressure

The single most important limitation is that the ultimate vacuum this pump can achieve is physically limited by the vapor pressure of the water it uses. As the system pressure drops, the water in the pump begins to boil, creating water vapor that prevents the vacuum from getting any deeper.

At 20°C (68°F), water's vapor pressure is about 2.3 kPa. This is why the pump's maximum vacuum is around 2 kPa—it simply cannot pull a vacuum deeper than the pressure of the water vapor it is creating.

Efficiency and Energy Use

These pumps are generally not highly efficient. A typical efficiency rating is around 30%, though some higher-end models may reach 50%. For continuous, large-scale industrial operations, this could lead to significant energy costs compared to other vacuum technologies.

Potential for Water Vapor Contamination

Since the working fluid is water, the resulting vacuum will always contain a partial pressure of water vapor. For processes that are highly sensitive to moisture, this type of pump is unsuitable.

Making the Right Choice for Your Application

Selecting the right vacuum pump requires matching the technology's capabilities to your specific goal.

- If your primary focus is routine lab work like filtration, degassing, or simple distillation: This pump is an excellent, cost-effective, and durable choice.

- If your primary focus is achieving a deep vacuum for sensitive processes (<2 kPa): This pump is not suitable. You should consider an oil-sealed rotary vane pump or a dry scroll pump instead.

- If your primary focus is a completely moisture-free vacuum environment: This pump is the wrong tool. A dry diaphragm or scroll pump is necessary to avoid water vapor contamination.

Ultimately, the circulating water vacuum pump has earned its place as a trusted and valuable tool by reliably performing its intended function within its well-defined limits.

Summary Table:

| Aspect | Details |

|---|---|

| Ultimate Vacuum | ~2 kPa (limited by water vapor pressure) |

| Air Suction Rate | ~10 L/min |

| Water Circulation Rate | ~80 L/min |

| Efficiency | 30-50% |

| Common Uses | Filtration, distillation, degassing, drying |

| Ideal Settings | Educational labs, small-scale research |

| Limitations | Not for deep vacuum or moisture-sensitive processes |

Need a reliable vacuum solution for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your laboratory efficiency with tailored equipment!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- Why is it necessary to use alumina or ceramic crucibles during the high-temperature evaporation of magnesium? Ensure Purity and Process Integrity

- What are the material requirements for a quartz boat in APVT? Ensure High-Purity Sb2Se3 Nanowire Growth

- What function do high-strength graphite molds serve? Essential Roles in Ti-6Al-4V Vacuum Hot Pressing

- What are the primary functions of high-purity graphite crucibles? Optimize Mg-Zn-xSr Alloy Purity and Efficiency

- What is the function of the laboratory-scale condensation collection device? Optimize Multi-Stage Magnesium Separation

- What are the advantages of using a platinum crucible? Essential for High-Purity Alumino-Borosilicate Glass Synthesis

- Why are alumina liners and quartz boats selected as consumables for sintering lunar soil simulant? Key Material Roles

- What role do laboratory furnaces play in quality control? Ensure Material Integrity and Product Reliability