In short, selecting the right alumina ceramic furnace tube requires a careful evaluation of its ability to withstand your specific process conditions. The most critical factors are the maximum operating temperature, the chemical environment or atmosphere it will be exposed to, and its resistance to thermal shock from heating and cooling cycles.

Choosing an alumina tube is not about finding the single "best" product, but about matching the tube's material properties and physical dimensions to the precise thermal, chemical, and mechanical demands of your application to ensure safety, reliability, and process integrity.

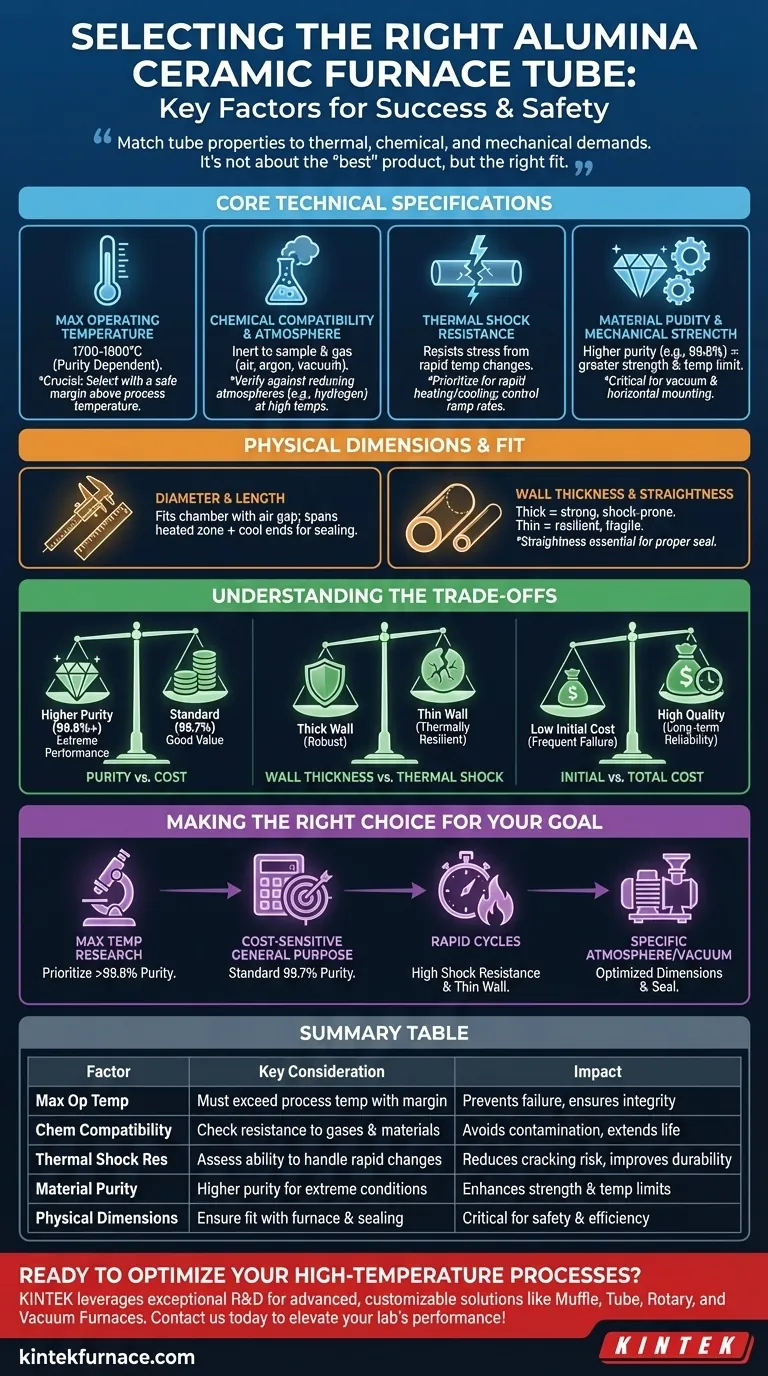

Core Technical Specifications

The performance of your entire high-temperature process hinges on the technical capabilities of the tube. Misjudging any of these core factors can lead to failed experiments, sample contamination, or catastrophic equipment failure.

Maximum Operating Temperature

Alumina tubes are defined by their ability to perform at high temperatures, but not all are created equal. The maximum use temperature for alumina is typically around 1700-1800°C, but this is highly dependent on the material's purity.

It is crucial to select a tube with a continuous operating temperature rating that provides a safe margin above your intended process temperature.

Chemical Compatibility and Atmosphere

The tube must remain inert and not react with your sample or the process atmosphere (e.g., air, inert gas like argon, or a vacuum). Alumina offers excellent resistance to most chemicals, but its performance can degrade in certain reducing atmospheres (like hydrogen) at very high temperatures.

Always verify that the alumina grade is compatible with the specific gases and materials you will be using to prevent sample contamination or premature tube failure.

Thermal Shock Resistance

Thermal shock is the stress induced in a material by rapid changes in temperature, and it is a primary cause of ceramic tube fracture. A tube's ability to resist this is determined by its material properties, wall thickness, and overall geometry.

If your process involves rapid heating or cooling, you must prioritize a tube with a high thermal shock resistance rating and implement controlled temperature ramp rates.

Material Purity and Mechanical Strength

The purity of the alumina (e.g., 99.7% vs. 99.8%) directly impacts its mechanical strength, density, and maximum operating temperature. Higher purity generally results in a denser, stronger ceramic that performs better at the upper limits of its temperature range.

This strength is critical for resisting physical stress, especially in vacuum applications or when the tube is horizontally mounted and subject to sagging over time.

Physical Dimensions and Fit

Even the highest-grade tube is useless if it doesn't integrate properly with your furnace. Precise dimensions are non-negotiable for both function and safety.

Diameter and Length

The tube's outer diameter must fit within your furnace's heating chamber with an appropriate gap for air circulation. The length must be sufficient to span the entire heated zone and extend into the cooler end zones, allowing for proper sealing and handling.

Wall Thickness and Straightness

Wall thickness is a direct trade-off. Thicker walls provide greater mechanical strength and rigidity but have lower resistance to thermal shock. Thinner walls heat and cool more evenly but are more fragile.

Straightness, or low camber, is essential for ensuring a proper seal with flanges and for applications involving sample insertion and removal.

Understanding the Trade-offs

An effective selection process involves balancing competing factors. Understanding these compromises is key to making a cost-effective and reliable choice.

Purity vs. Cost

Higher-purity alumina (99.8%+) offers superior performance at extreme temperatures and is often necessary for ultra-clean research environments. However, it comes at a significant cost premium.

For many industrial or general-purpose applications running at lower temperatures, a standard 99.7% purity tube provides an excellent balance of performance and value.

Wall Thickness vs. Thermal Shock

As mentioned, a thick-walled tube is mechanically robust but more prone to cracking during rapid temperature changes. A thin-walled tube is more thermally resilient but physically delicate.

Your choice should be dictated by whether your primary challenge is mechanical stress (e.g., heavy loads, long horizontal spans) or aggressive thermal cycling.

Initial Investment vs. Total Cost of Ownership

A low-cost tube may seem attractive upfront, but frequent failures lead to expensive downtime, wasted materials, and repeated replacement costs.

Investing in a high-quality tube from a reputable supplier often results in a lower total cost of ownership due to its longer lifespan, improved reliability, and the prevention of costly process failures.

Making the Right Choice for Your Goal

Your final decision should be guided by the single most important aspect of your work.

- If your primary focus is cutting-edge research at maximum temperatures: Prioritize the highest purity alumina (99.8% or greater) from a reputable supplier to ensure process integrity and minimal contamination.

- If your primary focus is a cost-sensitive, general-purpose application: A standard purity (99.7%) tube will likely offer the best balance of performance and budget, provided it meets your temperature needs.

- If your primary focus involves rapid heating and cooling cycles: Pay closest attention to thermal shock resistance ratings and consider a thinner-walled tube paired with controlled ramp rates.

- If your primary focus is maintaining a specific atmosphere or vacuum: Ensure the tube's dimensions, straightness, and end-finish are optimized for creating a perfect seal with your flanges.

Ultimately, selecting the right furnace tube is a critical step in ensuring the success and safety of your high-temperature process.

Summary Table:

| Factor | Key Consideration | Impact |

|---|---|---|

| Maximum Operating Temperature | Must exceed process temperature with a safe margin | Prevents tube failure and ensures process integrity |

| Chemical Compatibility | Check resistance to gases (e.g., hydrogen) and materials | Avoids contamination and extends tube life |

| Thermal Shock Resistance | Assess ability to handle rapid temperature changes | Reduces risk of cracking and improves durability |

| Material Purity | Higher purity (e.g., 99.8%) for extreme conditions | Enhances strength and temperature limits |

| Physical Dimensions | Ensure fit with furnace and proper sealing | Critical for safety and operational efficiency |

Ready to optimize your high-temperature processes with the perfect alumina ceramic furnace tube? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing reliability and efficiency. Contact us today to discuss how our tailored furnace tubes can elevate your lab's performance and safety!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What materials are used for the tube chamber in tubular furnaces? Choose the Right Tube for Your Lab's High-Temp Needs

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab