At its core, the advantage of a circulating water multifunctional vacuum pump is its ability to consolidate the functions of multiple pieces of laboratory equipment into a single, efficient, and clean unit. This design saves significant laboratory space, reduces initial equipment cost, and simplifies experimental setups by providing both vacuum and a circulating water supply from one machine.

The true value of this "multifunctional" design is not just versatility, but the underlying water-based mechanism. This eliminates oil contamination, dramatically reduces noise, and offers a level of operational simplicity and reliability that is ideal for many common laboratory applications.

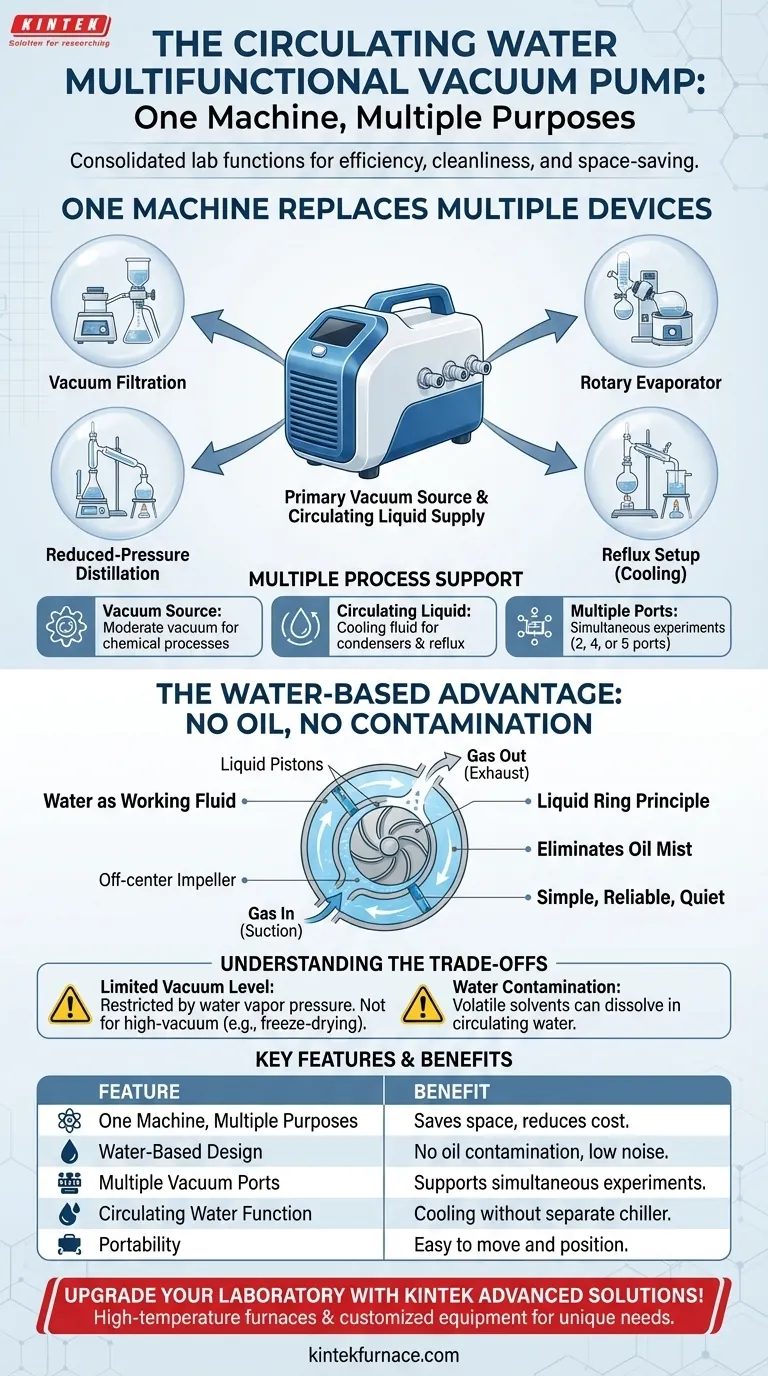

Deconstructing "One Machine, Multiple Purposes"

A single multifunctional unit replaces what would otherwise require several separate devices, streamlining the workflow in a busy lab environment.

It's a Primary Vacuum Source

The pump's main function is to generate a moderate vacuum. This is essential for a wide range of chemical processes, including vacuum filtration, solvent evaporation with a rotary evaporator, and reduced-pressure distillation.

It Provides a Circulating Liquid

The same water used to generate the vacuum can often be tapped to serve as a cooling fluid. This is invaluable for circulating through the condenser of a distillation apparatus or a reflux setup, eliminating the need for a separate chiller or a wasteful "once-through" tap water connection.

It Can Support Multiple Processes

Many models are equipped with multiple vacuum ports (two, four, or even five). This allows a single pump to serve several students or experiments simultaneously, maximizing resource utilization in a teaching or research lab.

The Advantage of a Water-Based Design

The use of water as the working fluid is the key innovation that delivers most of the pump's benefits. It operates on a principle known as a liquid-ring pump.

How It Works: The "Liquid Piston"

An off-center impeller (rotor) spins within the pump's housing, slinging water against the outer wall by centrifugal force. Because the impeller is eccentric, the space between its blades and the water ring constantly expands and contracts.

This creates a series of "liquid pistons." The expanding space draws gas in (suction), and the contracting space compresses and expels the gas (exhaust), creating a stable vacuum.

No Oil, No Contamination

Unlike traditional oil-sealed rotary vane pumps, this design is completely oil-free. This eliminates the risk of oil mist contaminating your experiment, which is critical for sensitive chemical analyses. It also means no messy oil changes or costly oil disposal.

Simple, Reliable, and Quiet

The design is mechanically simple, with low precision requirements, making it robust and easy to maintain. The water acts as both the sealant and lubricant, resulting in stable, reliable operation with very low noise and vibration compared to mechanical oil pumps.

Portability and Convenience

These pumps are often designed to be compact and are frequently equipped with casters. This makes them easy to move around the lab and position exactly where needed for a given experiment.

Understanding the Trade-offs

While highly advantageous for many applications, this technology is not a universal solution. Understanding its limitations is key to using it effectively.

Vacuum Level is Limited

The ultimate vacuum a water pump can achieve is limited by the vapor pressure of the water itself. As the pressure drops, the water will begin to boil, preventing a deeper vacuum. Performance degrades as the water temperature rises. For this reason, these pumps cannot achieve the high vacuum levels required for applications like freeze-drying or mass spectrometry.

Water Can Become Contaminated

While the pump won't contaminate your experiment with oil, volatile solvents from your experiment can be pulled into the pump and dissolve in the circulating water. This can degrade pump performance and may require the water to be treated as chemical waste when it's time to change it.

Making the Right Choice for Your Application

Selecting the correct vacuum source depends entirely on the demands of your specific procedure.

- If your primary focus is general chemistry or biology lab work (e.g., rotary evaporation, filtration, distillation): The multifunctional water pump is an excellent, cost-effective, and clean choice that simplifies your setup.

- If your primary focus is high-vacuum work that requires pressures below ~25 Torr (33 mbar): You will need a different technology, such as an oil-sealed rotary vane pump or a dry scroll pump, to reach the necessary vacuum level.

Ultimately, understanding the operational principle of a circulating water pump empowers you to choose the right tool for your scientific goal.

Summary Table:

| Key Feature | Benefit |

|---|---|

| One Machine for Multiple Purposes | Saves space and reduces equipment costs |

| Water-Based Design | Eliminates oil contamination and reduces noise |

| Multiple Vacuum Ports | Supports simultaneous experiments |

| Circulating Water Function | Provides cooling without a separate chiller |

| Portability | Easy to move and position in the lab |

| Limitations | Limited vacuum level; water can become contaminated |

Upgrade your laboratory with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces and customized equipment. Our products, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are designed to meet your unique experimental needs. Enhance efficiency and reliability—contact us today to discuss how we can support your lab's goals!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the sucking rate for a single tap on the water circulating vacuum pump? Get Key Specs for Your Lab

- Why is a vacuum pump used to evacuate the thermal modification chamber? Ensure Safety and Material Integrity

- What are the functions of alumina crucibles and quartz sleeve encapsulation in the synthesis of calcium perrhenates?

- Why is a corundum crucible required for the sintering of manganese ore at 1200 °C? Ensure High-Purity Results

- What types of trays are compatible with MoSi2 heating elements? Ensure Optimal Performance and Longevity

- What role does a high-precision mass flow controller play in assessing the gas selectivity of Gallium Sulfide sensors?

- How does the sealed Alumina Tube structure benefit the design of a reference electrode? Boost Electrolysis Precision

- How are laboratory vacuum pumps utilized in 1T-TaS2 crystal preparation? Ensure Peak Sample Purity