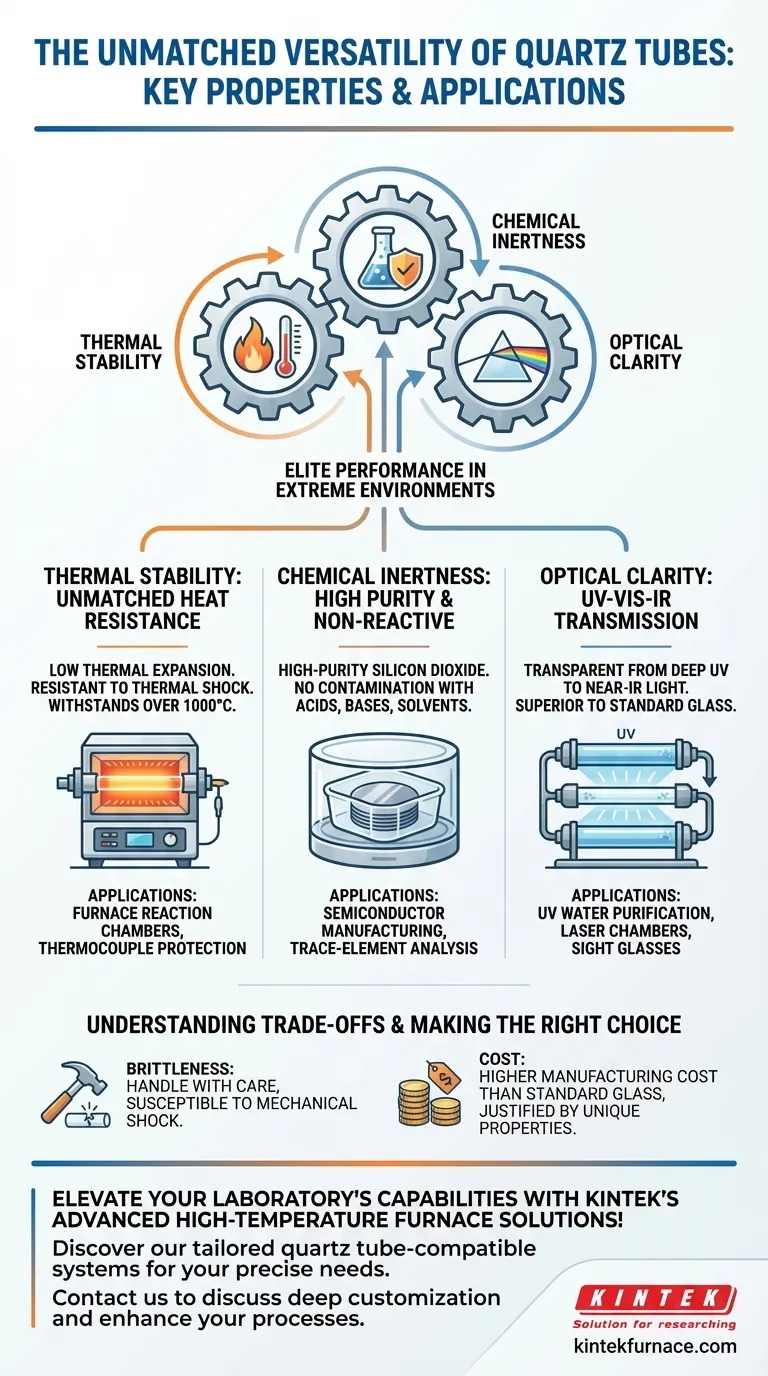

At its core, the versatility of quartz tubing stems from a unique combination of three key properties: exceptionally high thermal resistance, superior chemical inertness, and excellent optical clarity. This trifecta allows it to perform reliably in extreme environments where most other materials, including standard glass, would fail.

While many materials excel in one area, quartz is uniquely valuable because it delivers elite performance across thermal, chemical, and optical demands simultaneously. Understanding this synergy is the key to leveraging it effectively.

The Three Pillars of Quartz Performance

The value of quartz isn't just in one standout feature, but in the intersection of its core properties. Each one enables a specific set of demanding applications.

Unmatched Thermal Stability

Quartz, specifically fused quartz, possesses an extremely low coefficient of thermal expansion. This means it can withstand very high temperatures—often over 1000°C—without deforming or breaking.

It is also highly resistant to thermal shock. You can rapidly heat or cool a quartz tube without the risk of it shattering, a critical feature for processes involving rapid temperature cycling.

This thermal resilience is why quartz is the default choice for protective tubes for thermocouples and for reaction chambers in high-temperature laboratory furnaces.

Exceptional Chemical Purity and Inertness

Quartz tubes are composed of high-purity silicon dioxide, making them chemically inert to a wide range of substances. They will not react with or contaminate most acids, bases, or organic solvents.

This property is non-negotiable in environments where sample purity is paramount, such as in semiconductor manufacturing or trace-element analysis.

The inertness also contributes to the material's long lifespan, as it resists corrosion that would degrade lesser materials over time.

Superior Optical Clarity

Quartz is transparent across a very broad spectrum of light, from deep ultraviolet (UV) to near-infrared (IR). Standard glass, by contrast, blocks most UV light.

This makes quartz tubes essential for applications that rely on light transmission, such as UV water purification systems, laser chambers, and industrial sight glasses that require clear visibility into a process.

From Property to Practical Application

These fundamental properties translate directly into practical uses across science and industry.

In High-Purity Laboratory Environments

In research settings, quartz tubes are used as reaction chambers for processes like annealing, sintering, and calcination.

When fitted with flanges, they create a sealed, controlled atmosphere that is both chemically pure and capable of withstanding extreme heat from a tube furnace.

Specialized quartz "boats" are also used as sample holders to carry materials or wafers into these hot zones without introducing contaminants.

For Demanding Industrial Processes

In industrial settings, quartz tubes serve as durable sight glasses and level gauges, allowing operators to safely monitor processes inside high-temperature or corrosive environments.

Their structural integrity also makes them suitable for components in high-vacuum systems where outgassing from other materials would be a problem.

In Semiconductor Manufacturing

The semiconductor industry relies heavily on quartz for its extreme purity. Quartz tubes and carriers are used to hold and process silicon wafers at high temperatures.

Because the quartz does not leach impurities, it ensures the electrical properties of the semiconductor are not compromised during manufacturing.

Understanding the Trade-offs

No material is perfect. Acknowledging the practical trade-offs of quartz is essential for making an informed decision.

The Benefit of Durability and a Smooth Surface

Quartz has a very hard and smooth surface that is resistant to scratches and wear. This non-porous surface minimizes the buildup of residue, which simplifies cleaning and reduces operational downtime.

The Key Limitation: Brittleness

While thermally robust, quartz is a glass and remains a brittle material. It has high compressive strength but can shatter from a sharp mechanical shock or impact.

It cannot be treated like a metal pipe; careful handling is always required, especially during installation and maintenance.

The Cost Factor

Fused quartz is significantly more expensive to manufacture than common borosilicate (Pyrex) or soda-lime glass. Its production requires higher temperatures and more complex processes.

This cost means it is generally reserved for applications where its unique properties are a strict requirement, not just a preference.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary goal.

- If your primary focus is high-temperature processing (>500°C): Quartz is the superior choice for its thermal stability and resistance to thermal shock.

- If your primary focus is preventing sample contamination: The chemical inertness of quartz makes it essential for high-purity work in labs and semiconductor fabrication.

- If your primary focus is UV light transmission: Quartz is the only practical option, as standard glass blocks the UV spectrum.

- If your primary focus is cost-sensitivity with moderate demands: Borosilicate glass may be a suitable alternative for lower-temperature applications that do not require UV transparency.

Ultimately, choosing quartz is an investment in reliability for conditions that push beyond the limits of conventional materials.

Summary Table:

| Property | Key Characteristics | Common Applications |

|---|---|---|

| Thermal Stability | Low thermal expansion, resistant to thermal shock up to 1000°C | High-temperature furnaces, thermocouple protection |

| Chemical Inertness | High-purity silicon dioxide, non-reactive with acids and bases | Semiconductor manufacturing, trace-element analysis |

| Optical Clarity | Transparent from UV to IR light | UV water purification, laser chambers, sight glasses |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable quartz tube-compatible systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for high purity, thermal stability, and optical clarity. Contact us today to discuss how our tailored solutions can enhance your processes and drive innovation!

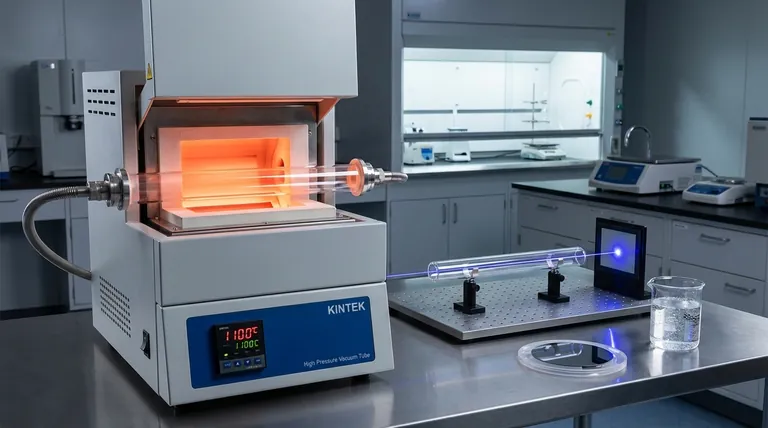

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing

- What is the significance of porcelain furnaces in academic and scientific research? Unlock Innovation with Precise High-Temperature Control