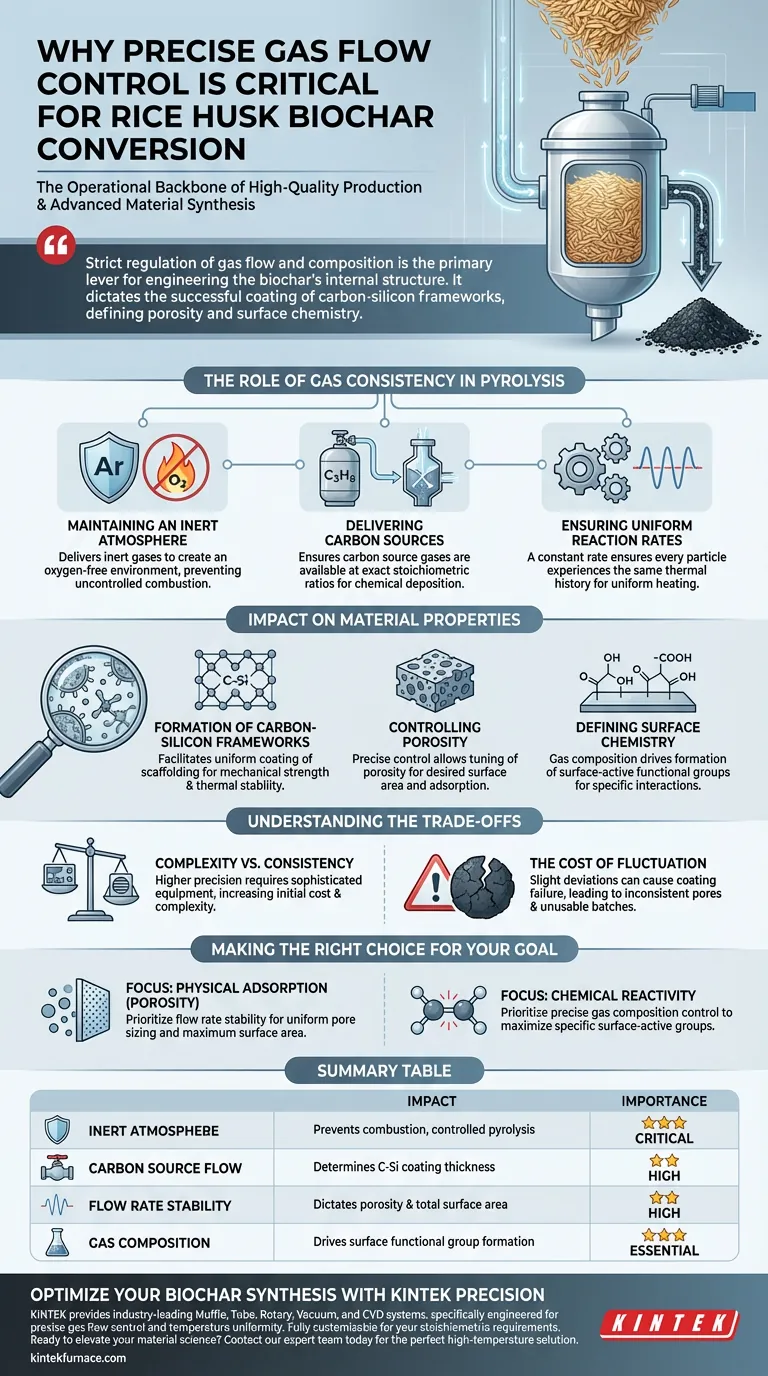

A precise gas flow control and supply system is the operational backbone of high-quality rice husk biochar production. It ensures the unwavering delivery of inert gases (such as argon) or carbon source gases (such as propane) at a constant, predetermined rate. Without this mechanical stability, the thermochemical conversion process becomes erratic, making it impossible to achieve the controlled pyrolysis environment necessary for advanced material synthesis.

Strict regulation of gas flow and composition is the primary lever for engineering the biochar’s internal structure. It dictates the successful coating of carbon-silicon frameworks, which in turn defines the material's porosity and surface chemistry.

The Role of Gas Consistency in Pyrolysis

To transform raw rice husk into engineered biochar, the reaction environment must remain stable. The gas supply system is the primary tool for maintaining this equilibrium.

Maintaining an Inert Atmosphere

The system must deliver inert gases, like argon, to create an oxygen-free environment. This prevents uncontrolled combustion of the biomass, ensuring the material undergoes pyrolysis rather than burning away.

Delivering Carbon Sources

For specific applications, carbon source gases like propane are introduced. A precise flow ensures these gases are available at the exact stoichiometric ratios required for chemical deposition.

Ensuring Uniform Reaction Rates

Fluctuations in gas flow lead to uneven heating and reaction speeds within the reactor. A constant rate ensures that every particle of rice husk experiences the same thermal history.

Impact on Material Properties

The ultimate goal of the gas system is to engineer the microscopic properties of the final product. The precision of the flow directly correlates to the quality of the biochar microcapsules.

Formation of Carbon-Silicon Frameworks

Rice husks are unique due to their high silica content. Precise gas flow facilitates the uniform coating of carbon-silicon frameworks, a structural scaffolding that provides mechanical strength and thermal stability.

Controlling Porosity

The flow rate determines how volatiles escape and how new structures form. Precise control allows you to "tune" the porosity, determining the surface area available for adsorption or catalytic activity.

Defining Surface Chemistry

The composition of the gas stream drives the formation of surface-active functional groups. These chemical groups determine how the biochar interacts with other substances, such as pollutants in water filtration or nutrients in soil amendment.

Understanding the Trade-offs

While high-precision gas systems offer superior control, they introduce specific challenges that must be managed.

Complexity vs. Consistency

Implementing a system capable of nanometer-level precision requires sophisticated mass flow controllers and monitoring equipment. This increases the initial capital cost and operational complexity compared to simple, passive venting systems.

The Cost of Fluctuation

If the gas flow deviates even slightly, the "coating" mechanism can fail. This results in biochar with inconsistent pore sizes or incomplete surface activation, rendering the batch unsuitable for high-performance applications.

Making the Right Choice for Your Goal

The level of precision required in your gas supply system depends on the intended application of your rice husk biochar.

- If your primary focus is Physical Adsorption (Porosity): Prioritize flow rate stability to ensure uniform pore sizing and maximum surface area within the carbon-silicon framework.

- If your primary focus is Chemical Reactivity: Prioritize precise gas composition control to maximize the formation of specific surface-active functional groups.

Mastering gas flow is not just about keeping the process running; it is the difference between burning waste and engineering a functional nanomaterial.

Summary Table:

| Feature | Impact on Biochar Production | Importance Level |

|---|---|---|

| Inert Atmosphere | Prevents combustion and ensures controlled pyrolysis. | Critical |

| Carbon Source Flow | Determines the thickness of carbon-silicon coating layers. | High |

| Flow Rate Stability | Dictates internal porosity and total surface area. | High |

| Gas Composition | Drives the formation of specific surface-active functional groups. | Essential |

Optimize Your Biochar Synthesis with KINTEK Precision

High-performance biochar requires the unwavering stability of professional thermal processing equipment. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered to deliver the precise gas flow control and temperature uniformity your research demands. Our systems are fully customizable to meet the unique stoichiometric requirements of your carbon-silicon framework engineering.

Ready to elevate your material science? Contact our expert team today to find the perfect high-temperature solution tailored to your laboratory's needs.

Visual Guide

References

- Alibek Mutushev, Dauren Mukhanov. Development and application of microcapsules based on rice husk and metallurgical sludge to improve soil fertility. DOI: 10.1038/s41598-024-73329-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Induction Melting Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What advantages do boron nitride (BN) crucibles offer for molten FUNaK salt? Ensure Purity & High-Temp Stability

- What is the role of vacuum pressure impregnation equipment in full-cell saturation tests? Ensure Precise ASE Analysis

- Where are water circulating vacuum pumps commonly used? Essential for Lab and Industrial Vapor Handling

- What role do high-purity graphite crucibles play in Boron Carbide sintering? Optimize Ceramic Purity and Density

- What processes is the circulating water multifunctional vacuum pump suitable for? Ideal for Clean, Economical Lab Vacuum Needs

- What is the function of a vacuum ampoule during the synthesis of ZnGeP2? Ensure Purity and Chemical Stability

- What is the maximum vacuum capacity of the water circulating vacuum pump? Uncover Its Ideal Lab Applications

- Why is zirconia grinding media preferred for NN-10ST ceramic powders? Ensure Purity & Dielectric Performance