Fundamentally, a circulating water vacuum pump is a versatile tool for any process requiring a moderate, clean vacuum. It is specifically designed for laboratory and small-scale production environments, making it ideal for processes like evaporation, distillation, crystallization, drying, sublimation, filtration, decompression, and degassing.

The core value of a circulating water vacuum pump lies in its simplicity. It uses water—not oil—to create a vacuum, offering an economical, low-noise, and contamination-free solution for a wide range of common scientific applications.

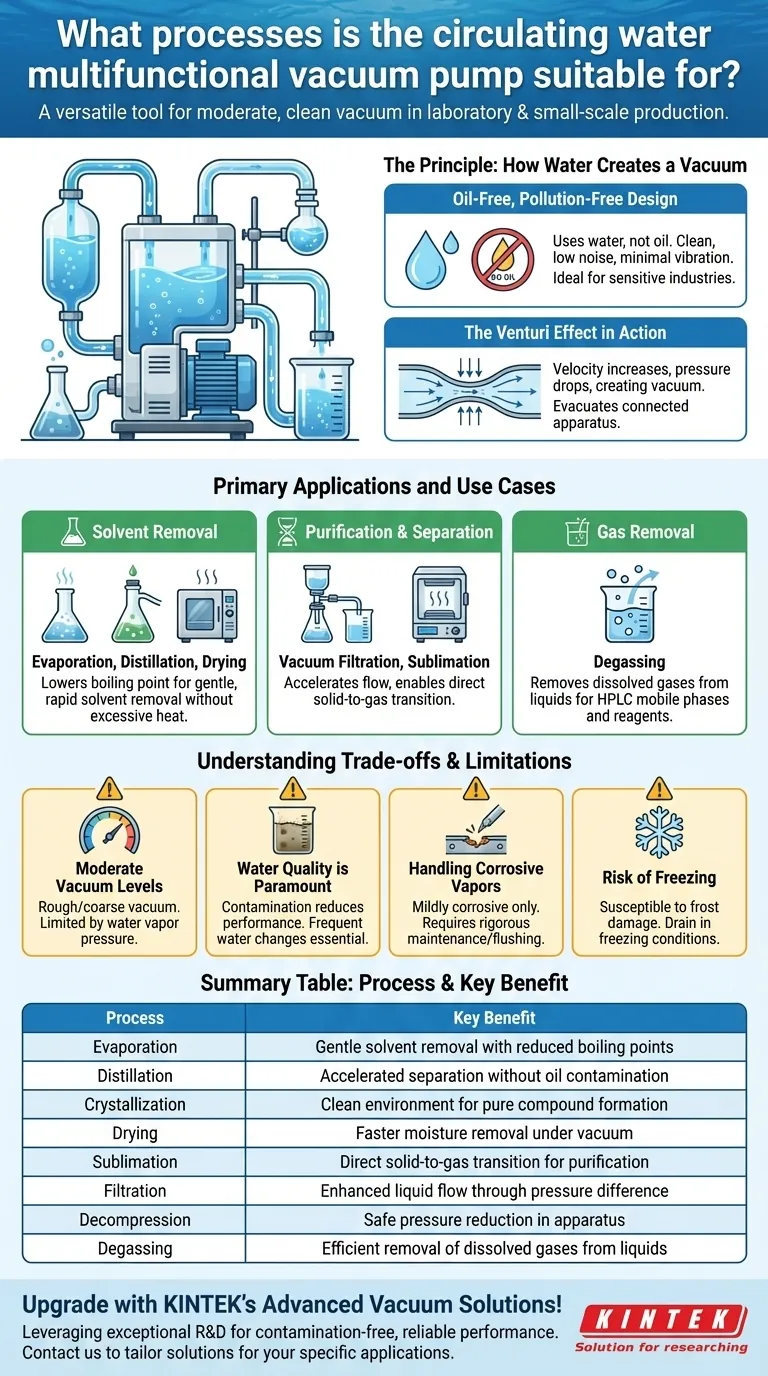

The Principle: How Water Creates a Vacuum

A circulating water pump's design is elegant in its simplicity. Understanding its mechanism helps clarify its ideal uses and its limitations.

An Oil-Free, Pollution-Free Design

Unlike traditional rotary vane pumps that use oil as a sealant and lubricant, this pump uses a continuously circulating stream of water.

This makes it inherently clean, preventing oil vapors from contaminating your experiment or final product. This is critical in industries like pharmaceuticals, biochemistry, and food science.

The design also results in low noise and minimal vibration, making it a convenient and non-disruptive addition to a busy lab environment.

The Venturi Effect in Action

The pump works by forcing water through a specially shaped nozzle called a venturi. As the water is forced through the narrowest point, its velocity increases dramatically.

This increase in velocity causes a sharp drop in pressure, creating a vacuum. This vacuum is then used to evacuate the connected apparatus.

Primary Applications and Use Cases

This pump is a workhorse for applications that benefit from a reduction in atmospheric pressure but do not require an ultra-high vacuum.

Processes Requiring Solvent Removal

Applications like evaporation, distillation, and drying are significantly accelerated by a vacuum.

By lowering the ambient pressure, you lower the boiling point of liquids. This allows for the gentle and rapid removal of solvents without having to apply excessive heat, which could damage sensitive compounds.

Processes for Purification and Separation

In vacuum filtration, the pressure difference across the filter paper pulls the liquid through much faster than gravity alone.

For sublimation, applying a vacuum helps a solid transition directly into a gas, which is a key step in purifying certain compounds.

Processes for Gas Removal

Degassing is the process of removing dissolved gases from a liquid. A vacuum encourages these dissolved gases to come out of the solution. This is essential for preparing HPLC mobile phases or other reagents where gas bubbles would interfere with the process.

Understanding the Trade-offs and Limitations

While versatile, the circulating water vacuum pump is not the right tool for every job. Objectivity requires acknowledging its limitations.

Moderate Vacuum Levels

These pumps produce a "rough" or "coarse" vacuum. The ultimate vacuum level is physically limited by the vapor pressure of the water being used, which is dependent on its temperature.

If your process requires a high vacuum (a very low pressure), you will need a more advanced system, such as a rotary vane pump or a turbomolecular pump.

Water Quality is Paramount

The pump's performance is directly tied to the cleanliness of the water in its reservoir. As the pump pulls in vapors from your process, these can condense and accumulate in the water.

Contaminated water, or water that has become saturated with solvent vapors, will have a higher vapor pressure, which directly reduces the pump's ability to create a strong vacuum. Frequent water changes are not optional; they are essential for consistent performance.

Handling Corrosive Vapors

While the pump can handle mildly corrosive vapors, these materials will contaminate the water and can degrade the pump's internal components over time.

If you must pump corrosive gases, you must commit to a more frequent water replacement schedule to flush the corrosive materials out of the system.

Risk of Freezing

Because the pump relies on water, it is susceptible to damage from freezing temperatures. If the pump is stored in an environment that drops below 0°C (32°F), you must drain all water from the reservoir and lines to prevent frost damage.

Making the Right Choice for Your Application

To determine if this pump is correct for your needs, consider your primary goal.

- If your primary focus is routine solvent evaporation or vacuum filtration: This pump is an excellent, cost-effective choice due to its simplicity and oil-free operation.

- If you are working with highly sensitive materials that cannot tolerate oil contamination: The inherent cleanliness of a water-based system makes this the superior option over a standard oil pump.

- If you are working with volatile or mildly corrosive vapors: This pump is suitable, provided you are prepared for a rigorous maintenance schedule with frequent water changes to protect the equipment.

- If your process requires a very deep vacuum for applications like mass spectrometry or surface science: This type of pump is insufficient on its own and a more advanced high-vacuum system is required.

By understanding its principles and limitations, you can effectively leverage the circulating water vacuum pump as a reliable workhorse in your lab.

Summary Table:

| Process | Key Benefit |

|---|---|

| Evaporation | Gentle solvent removal with reduced boiling points |

| Distillation | Accelerated separation without oil contamination |

| Crystallization | Clean environment for pure compound formation |

| Drying | Faster moisture removal under vacuum |

| Sublimation | Direct solid-to-gas transition for purification |

| Filtration | Enhanced liquid flow through pressure difference |

| Decompression | Safe pressure reduction in apparatus |

| Degassing | Efficient removal of dissolved gases from liquids |

Upgrade your laboratory efficiency with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, all backed by deep customization to meet your unique needs. Whether you're in pharmaceuticals, biochemistry, or materials science, our oil-free circulating water vacuum pumps and other products ensure contamination-free, reliable performance. Contact us today to discuss how we can tailor solutions for your specific applications and boost your productivity!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is the technical objective of using vacuum-sealed quartz capsules for Co-Ti-V alloy homogenization? Safeguard Chemical Integrity

- What is the function of a vacuum system in PLD? Ensure High-Density, Pure Electrolyte Thin Films

- How do a precision hydraulic press and high-strength stainless steel molds facilitate boron carbide green body forming?

- What are the material requirements for the core reaction chambers? Ensure Pure Pyrolysis with Quartz and Corundum

- Why is a vacuum pump system integrated into a plastic pyrolysis setup? Optimize Yield and Energy Efficiency

- Why is a carrier gas flow control system necessary for thermal sludge treatment? Ensure Precision & Protect Equipment

- Why is the selection of crucibles with specific internal linings necessary? Protect Purity in Superalloy Melting

- What are the functions of a high-purity graphite mold during the SPS process? Beyond Containing the Powder