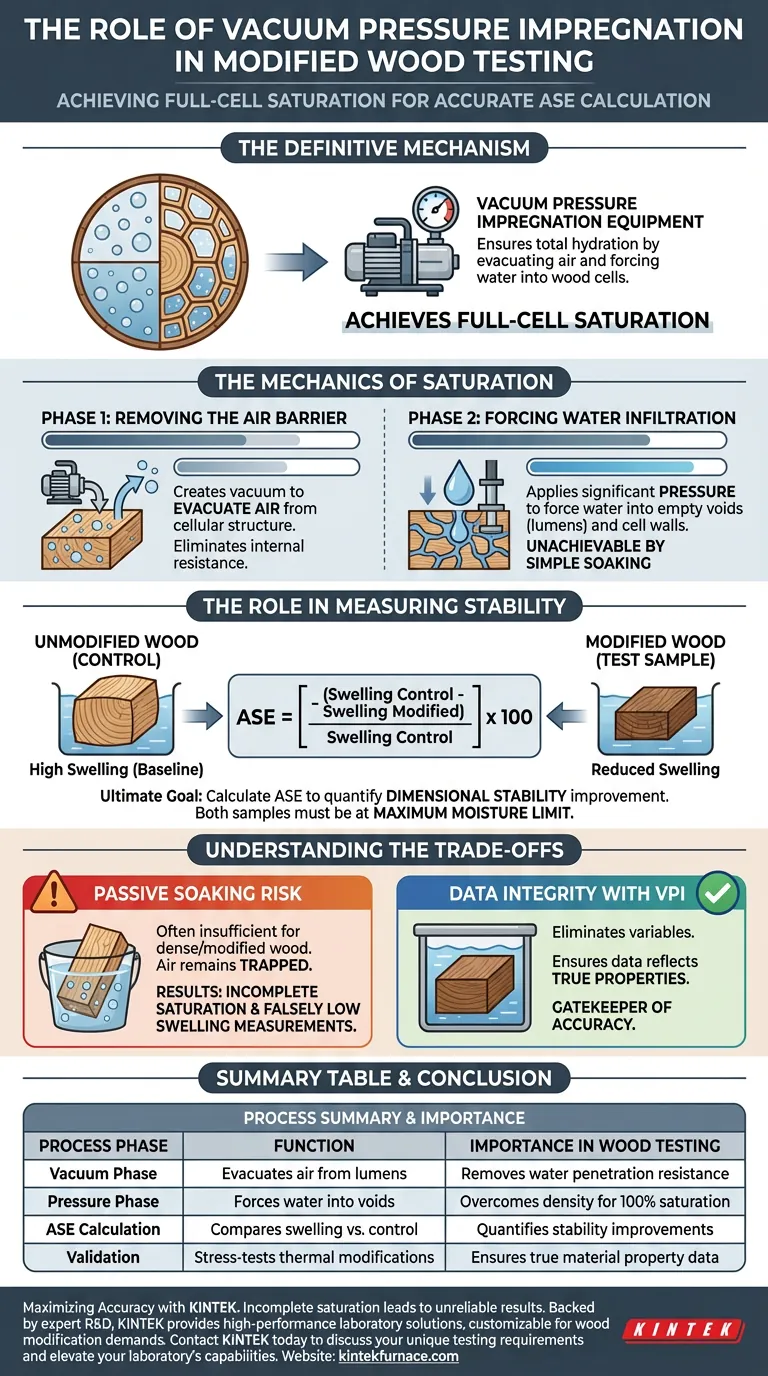

Vacuum pressure impregnation equipment serves as the definitive mechanism for achieving total hydration in wood samples during testing. It operates by first creating a vacuum to evacuate air from the wood's cellular structure, then applying significant pressure to force water deep into the cells, ensuring a state of full-cell saturation.

The primary purpose of this equipment is to enable the accurate calculation of Anti-Swelling Efficiency (ASE). By guaranteeing complete saturation, it provides the necessary baseline to quantify how effectively thermal modification improves the wood's dimensional stability.

The Mechanics of Saturation

Removing the Air Barrier

Wood is naturally porous and filled with air pockets. To test its maximum swelling potential, this air must be removed.

The equipment initiates a vacuum phase to extract air from the wood cells. This eliminates the internal resistance that would otherwise prevent water from penetrating deeply.

Forcing Water Infiltration

Once the air is evacuated, the equipment shifts to a pressure phase. This step is critical for overcoming the natural density of the wood.

High pressure forces water into the now-empty voids (lumens) and cell walls. This ensures the wood reaches a state of full saturation, which is impossible to achieve through simple soaking.

The Role in Measuring Stability

Determining Anti-Swelling Efficiency (ASE)

The ultimate goal of using this equipment is to calculate the ASE. This metric is the standard for assessing the quality of modified wood.

ASE compares the swelling of modified wood against unmodified wood. To make this comparison valid, both samples must be pushed to their absolute moisture limit.

Validating Thermal Modification

Thermal modification is performed specifically to stop wood from changing shape when wet.

This equipment acts as the stress test for that process. It reveals whether the modification successfully reduced the wood's tendency to absorb water and swell.

Understanding the Trade-offs

The Risk of Passive Soaking

Without vacuum pressure equipment, researchers often rely on passive soaking. This is frequently insufficient for dense or modified wood.

Passive methods leave air trapped inside the cells. This results in incomplete saturation, leading to falsely low swelling measurements.

Data Integrity Dependence

The reliability of your stability data relies entirely on the impregnation process.

If the wood is not fully saturated, the ASE calculation will be skewed. This equipment eliminates that variable, ensuring the data reflects the true properties of the modified wood.

Making the Right Choice for Your Analysis

If your primary focus is measuring modification quality:

- Ensure your equipment can achieve high enough vacuum and pressure levels to fully penetrate the specific density of wood you are testing.

If your primary focus is comparative research:

- Standardize the vacuum/pressure cycles strictly to ensure that ASE calculations between different batches are mathematically comparable.

This equipment is not just a saturator; it is the gatekeeper of accuracy for any claim regarding wood dimensional stability.

Summary Table:

| Process Phase | Function | Importance in Wood Testing |

|---|---|---|

| Vacuum Phase | Evacuates air from cellular lumens | Removes internal resistance to water penetration |

| Pressure Phase | Forces water into empty cell voids | Overcomes wood density for 100% saturation |

| ASE Calculation | Compares swelling vs. control | Quantifies dimensional stability improvements |

| Validation | Stress-tests thermal modifications | Ensures data reflects true material properties |

Maximize the Accuracy of Your Material Stability Tests

Incomplete saturation leads to skewed data and unreliable results. At KINTEK, we understand that your research depends on precision. Backed by expert R&D and manufacturing, we provide high-performance laboratory solutions—including advanced Vacuum, CVD systems, and Muffle furnaces—all customizable to meet the rigorous demands of wood modification and material science.

Whether you are calculating Anti-Swelling Efficiency (ASE) or validating thermal treatments, our equipment delivers the control you need for definitive results. Contact KINTEK today to discuss your unique testing requirements and discover how our specialized systems can elevate your laboratory’s capabilities.

Visual Guide

References

- Guntis Sosins, Jānis Zicāns. Water-Related Properties of Wood after Thermal Modification in Closed Process under Pressure in Nitrogen. DOI: 10.3390/f15010140

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of high-purity Alumina (Al2O3) crucibles? Enhance Accuracy in Molten Salt Electrochemical Studies

- Why is a Pt5%Au crucible required for S53P4 bioactive glass? Ensure Purity at 1400°C

- What roles do ceramic crucibles play in 500 °C pre-calcination? Ensure Pure Layered Oxide Synthesis

- Why is a Boron Nitride (BN) crucible ideal for high-temp graphite catalyst treatment? Ensure Purity & Sample Integrity

- How do multi-bore high-purity alumina tubes stabilize CV tests? Enhance Data Accuracy with KINTEK Solutions

- How do alumina ceramic furnace tubes compare to other materials like quartz or silicon carbide? Choose the Best for Your High-Temp Needs

- What is the function of high-purity graphite molds during SPS of Cu2Se? Essential Tips for Superior Sintering

- Why use graphite or quartz crucibles for liquid antimony-tellurium? Protect Your High-Temp Melt Integrity