A laboratory vacuum drying oven is indispensable for processing sensitive nano metal-organic framework (MOF) materials like nLn-bdc. By significantly reducing the system pressure, the oven forces residual washing solvents—specifically ethanol—to evaporate rapidly at much lower temperatures than standard atmospheric drying would require.

By decoupling evaporation from high heat, vacuum drying preserves the delicate crystalline structure of nano MOFs. This process is the only reliable way to ensure the material's pores remain open and active for subsequent photoluminescence and electrical property measurements.

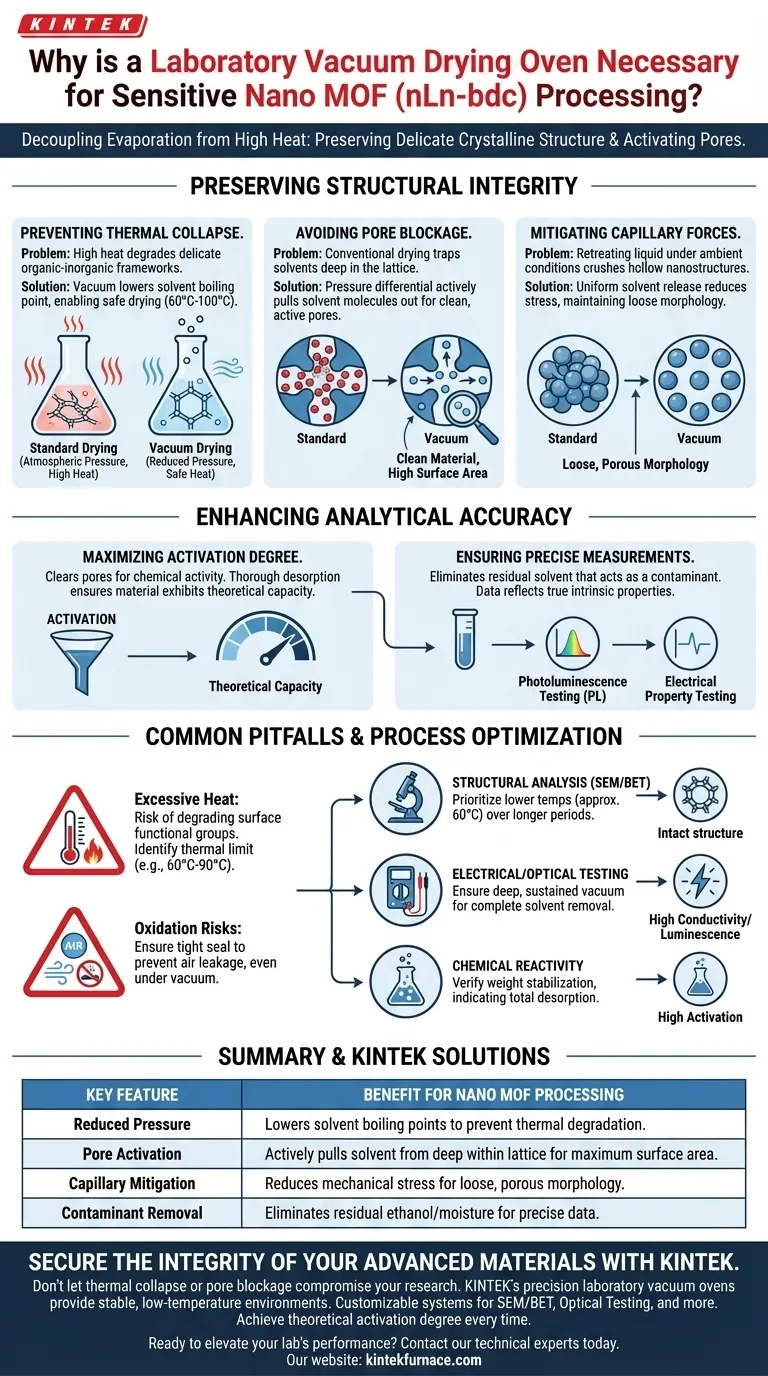

Preserving Structural Integrity

Preventing Thermal Collapse

The primary danger to nano MOF materials like nLn-bdc is heat sensitivity. High temperatures required to dry these materials at normal air pressure can cause the delicate organic-inorganic framework to collapse or degrade.

By lowering the pressure, the vacuum oven lowers the boiling point of solvents. This allows you to remove moisture and ethanol at safe temperatures (often between 60°C and 100°C), ensuring the skeletal structure remains intact.

Avoiding Pore Blockage

For an MOF to function, its pores must be empty. Conventional drying often leaves trapped solvent molecules deep within the lattice.

Vacuum drying creates a pressure differential that actively pulls these solvent molecules out of the pores. This prevents pore blockage, resulting in a "clean" material with a high surface area available for interaction.

Mitigating Capillary Forces

When solvents evaporate from nanostructures under ambient conditions, the retreating liquid can create strong capillary forces. These forces are often strong enough to crush hollow nanostructures or cause agglomeration.

The vacuum environment facilitates a more uniform release of solvents. This reduces the mechanical stress on the material, maintaining the loose, porous morphology required for optimal performance.

Enhancing Analytical Accuracy

Maximizing Activation Degree

"Activation" refers to the process of clearing the pores to make the MOF chemically active. A material that retains solvent is considered partially inactive.

The thorough removal of physically adsorbed molecules via vacuum drying maximizes the activation degree. This ensures that the material exhibits its theoretical capacity during application.

Ensuring Precise Measurements

Analytical techniques such as photoluminescence and electrical property testing are highly sensitive to impurities. Residual solvent acts as a contaminant that can skew results.

Vacuum drying eliminates these artifacts. It ensures that the data you collect reflects the true intrinsic properties of the nLn-bdc framework, rather than the noise of trapped ethanol or moisture.

Common Pitfalls to Avoid

The Risk of Excessive Heat

While vacuum allows for lower temperatures, it does not make the material immune to heat. Even under vacuum, setting the oven temperature too high can still degrade surface functional groups.

You must identify the specific thermal limit of your MOF (e.g., nLn-bdc) and set the vacuum oven well below this threshold. The references suggest ranges between 60°C and 90°C are often optimal for similar precursors.

Oxidation Risks

Although vacuum drying significantly reduces oxygen presence, it may not create a completely anaerobic environment depending on the pump quality.

If your material is extremely sensitive to oxidation, rely on the vacuum primarily to lower the boiling point, but ensure the seal is tight to prevent continuous air leakage during the drying cycle.

Optimizing the Process for Your Goals

To get the most out of your nLn-bdc processing, tailor your approach based on your specific testing requirements:

- If your primary focus is Structural Analysis (SEM/BET): Prioritize lower temperatures (approx. 60°C) over longer periods to prevent any morphological collapse or agglomeration.

- If your primary focus is Electrical/Optical Testing: Ensure a deep, sustained vacuum to guarantee the complete removal of all solvent molecules that could interfere with conductivity or luminescence.

- If your primary focus is Chemical Reactivity: Focus on the "activation" aspect by verifying that the final weight stabilizes, indicating total solvent desorption.

Vacuum drying is not just a drying step; it is a critical preservation technique that defines the quality of your final data.

Summary Table:

| Key Feature | Benefit for Nano MOF (nLn-bdc) Processing |

|---|---|

| Reduced Pressure | Lowers solvent boiling points to prevent thermal degradation of organic frameworks. |

| Pore Activation | Actively pulls solvent molecules from deep within the lattice to maximize surface area. |

| Capillary Mitigation | Reduces mechanical stress during evaporation to maintain loose, porous morphology. |

| Contaminant Removal | Eliminates residual ethanol/moisture for precise photoluminescence and electrical testing. |

Secure the Integrity of Your Advanced Materials with KINTEK

Don't let thermal collapse or pore blockage compromise your research data. KINTEK’s precision laboratory vacuum ovens are engineered to provide the stable, low-temperature environments essential for sensitive nano-materials like MOFs.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet your unique experimental needs. Whether you are focused on SEM/BET analysis or complex optical testing, our technology ensures your materials achieve their theoretical activation degree every time.

Ready to elevate your lab's performance? Contact our technical experts today to find the perfect customized heating solution for your application.

Visual Guide

References

- Moritz Maxeiner, Klaus Müller‐Buschbaum. NanoMOF‐Based Multilevel Anti‐Counterfeiting by a Combination of Visible and Invisible Photoluminescence and Conductivity. DOI: 10.1002/adfm.202500794

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What customization options are available for alumina ceramic tubes? Tailor for High-Temp, Corrosion-Resistant Applications

- What is the point of a vacuum chamber? Achieve Absolute Control in Your Processes

- What are the primary functions of high-purity graphite crucibles? Optimize Mg-Zn-xSr Alloy Purity and Efficiency

- What are the specific functions of the grinder and laboratory oven during sugarcane-based activated carbon preparation?

- What mechanical properties should be evaluated for alumina ceramic furnace tubes? Ensure Durability and Performance

- Why is a laboratory pellet press used to compress powders? Optimize Conductivity for Flash Joule Heating

- Why is a high-performance vacuum pump system necessary for AlV55 alloys? Ensure Aerospace-Grade Purity and Precision

- What types of high-temperature laboratory furnace systems are available? Explore 5 Specialized Solutions