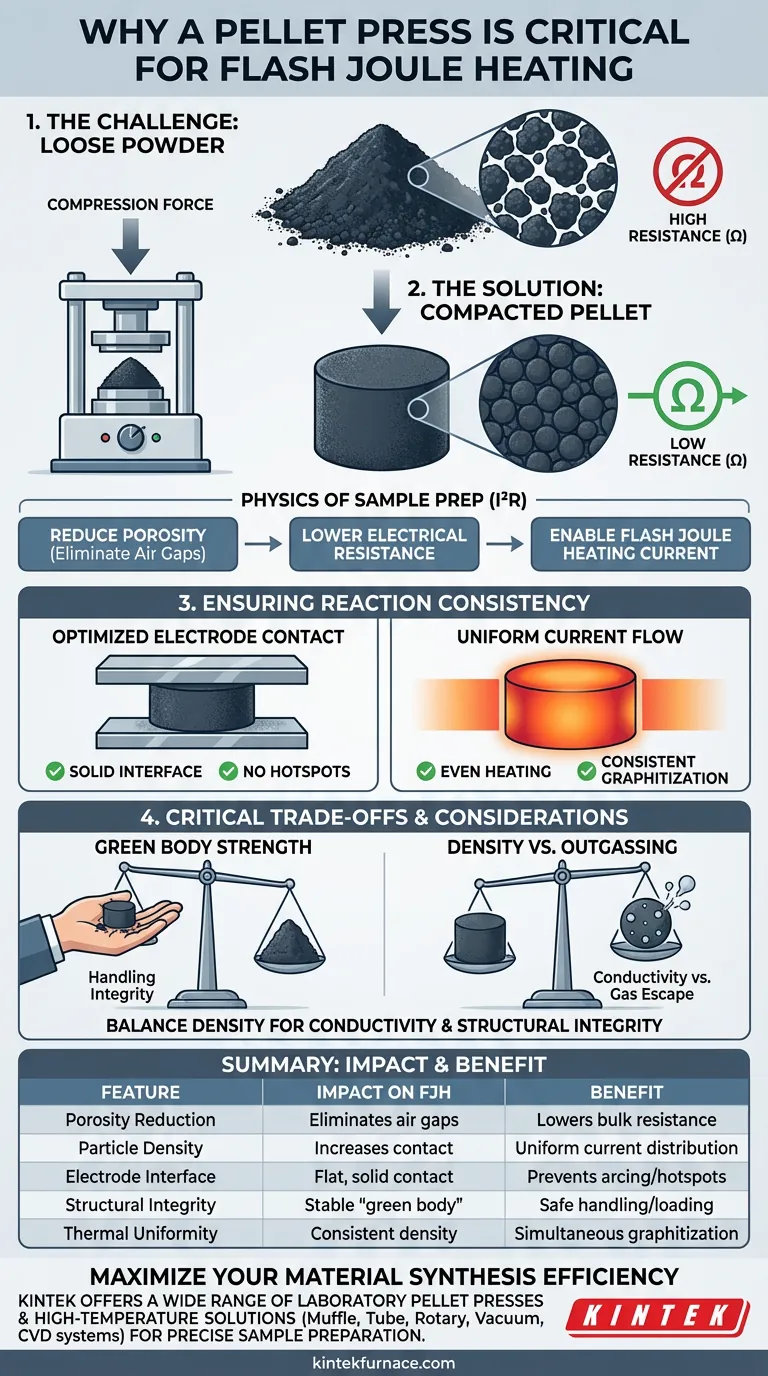

A laboratory pellet press serves a critical electrical function, not just a mechanical one. It compresses powders—such as human hair powder—into compact pellets to drastically reduce internal porosity. By eliminating air gaps, the press lowers the material's electrical resistance, enabling the current flow necessary for the Flash Joule Heating reaction to occur.

The press transforms loose, resistive powder into a conductive, dense pellet. This physical compaction ensures the optimal electrode contact and uniform current distribution required to achieve instantaneous ultra-high temperatures for graphitization.

The Physics of Sample Preparation

The Flash Joule Heating process relies on the principle of resistive heating ($I^2R$). To generate heat efficiently, the material must allow current to flow while offering enough resistance to generate thermal energy.

Reducing Internal Porosity

Loose powders naturally contain significant voids and air gaps between particles. Air is an electrical insulator, which creates excessive resistance in the raw sample.

The pellet press applies force to cause particle rearrangement, physically closing these gaps. This creates a dense structure where particles are in close proximity, significantly reducing the volume of insulating air.

Lowering Electrical Resistance

By reducing porosity, the press lowers the bulk electrical resistance of the sample.

This is the physical foundation of the reaction: without this step, the resistance might be too high for the current to initiate the flash. The compacted form ensures the voltage can drive a current through the material rather than arcing across the surface or failing to ignite.

Ensuring Reaction Consistency

Achieving high-quality graphitization requires the entire sample to experience the same temperature profile simultaneously.

Optimizing Electrode Contact

The primary reference highlights that a compact physical form ensures optimal contact between the sample and the electrodes.

If the powder is loose, contact with the electrodes is intermittent and weak. A pressed pellet provides a solid interface, ensuring the current enters the material efficiently without creating contact resistance hotspots.

Uniform Current Flow

A pressed pellet ensures that current flows uniformly through the material.

Because the density is consistent throughout the pellet, the heating effect is evenly distributed. This uniformity is essential for triggering efficient graphitization across the entire sample volume, rather than just in localized areas.

Critical Trade-offs and Considerations

While compression is vital, the mechanics of pressing introduce specific variables that must be managed to ensure success.

The "Green Body" Strength

As noted in supplementary documentation, pressing creates a "green body"—a formed pellet with enough mechanical strength to be handled.

This allows the sample to be moved from the press to the reaction chamber without crumbling. However, this structure relies on the correct application of pressure (e.g., 9800 N) to maintain its shape during the loading process.

Density vs. Outgassing

There is a balance to be struck regarding density. While high density improves conductivity, Flash Joule Heating generates gases as impurities are vaporized.

If a sample were hypothetically compressed to near-theoretical density, it might trap these gases, potentially causing structural failure of the pellet during the rapid expansion. The goal is a density that maximizes conductivity while maintaining structural integrity.

Making the Right Choice for Your Goal

When preparing samples for Flash Joule Heating, your pressing strategy controls the quality of the final graphitized product.

- If your primary focus is Heating Efficiency: Prioritize higher compression to minimize porosity and electrical resistance, ensuring the reaction triggers instantly.

- If your primary focus is Sample Handling: Ensure the pressure applied is sufficient to form a robust "green body" that does not delaminate or crumble before the reaction.

Proper compression is the bridge that turns a non-conductive powder into a reactive, conductive solid capable of withstanding ultra-high temperatures.

Summary Table:

| Feature | Impact on Flash Joule Heating | Benefit for Lab Research |

|---|---|---|

| Porosity Reduction | Eliminates air gaps (insulators) | Lowers bulk electrical resistance |

| Particle Density | Increases particle-to-particle contact | Ensures uniform current distribution |

| Electrode Interface | Provides flat, solid contact area | Prevents hotspots and surface arcing |

| Structural Integrity | Creates a stable "green body" | Allows safe handling and sample loading |

| Thermal Uniformity | Consistent density throughout | Achieves simultaneous graphitization |

Maximize Your Material Synthesis Efficiency

Precise sample preparation is the foundation of successful Flash Joule Heating. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory pellet presses and high-temperature solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique research needs.

Whether you are working on graphitization, carbon nanotubes, or advanced ceramic synthesis, our precision tools ensure your samples achieve the density and conductivity required for instantaneous reaction success. Contact KINTEK today to find the perfect press for your lab!

Visual Guide

References

- Jasreet Kaur, José A. Alarco. Sustainable Manufacturing of Graphitic Carbon from Bio‐Waste Using Flash Heating for Anode Material of Lithium‐Ion Batteries with Optimal Performance. DOI: 10.1002/adsu.202300610

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are quartz tubes indispensable in advanced technologies? Unlock Purity and Performance

- What safety and environmental roles do lab exhaust and flare systems play in pyrolysis? Ensure a Secure Lab Workspace

- Why is a BN coating used in Mg3Sb2 melting? Essential Purity and Protection Guide

- Why are high-purity alumina crucibles used for MAX phase sintering? Ensure Purity in High-Temperature Synthesis

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What are the technical advantages of using ceramic crucibles for moxa floss pyrolysis? Ensure Precise Thermal Analysis

- What are tube furnace tubes made of? Select the Right Material for Your Process

- Why use a covered crucible for g-C3N4 calcination? Enhance Surface Area via Self-Exfoliation