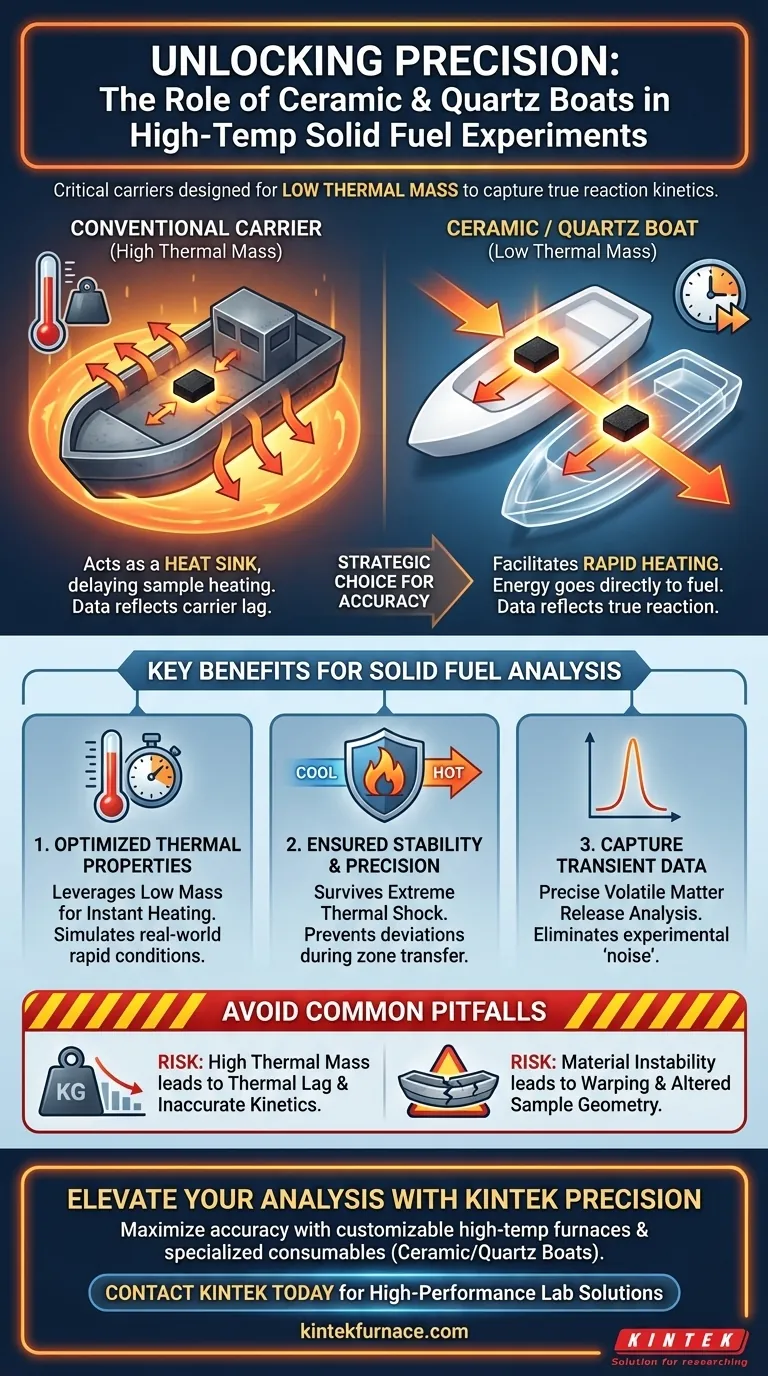

Ceramic or quartz sample boats act as critical, specialized carriers for solid fuel samples in high-temperature environments, specifically designed to minimize experimental interference. Their significance lies in their ability to facilitate rapid heating while maintaining structural integrity when moved from low-temperature zones to the furnace's high-temperature center.

Core Takeaway: The use of ceramic or quartz is not merely for containment; it is a strategic choice to ensure low thermal mass. This property prevents the sample holder from acting as a heat sink, ensuring that recorded data reflects the true reaction kinetics of the fuel rather than the heating lag of the carrier.

The Critical Role of Thermal Properties

Leveraging Low Thermal Mass

In high-temperature experiments, the vessel holding the sample can often distort the results. Ceramic and quartz boats are engineered with low thermal mass.

This ensures that the energy provided by the furnace is directed primarily into the solid fuel sample, rather than being absorbed by the boat itself.

Facilitating Rapid Heating

To study combustion or pyrolysis accurately, the fuel often needs to reach the target temperature almost instantly.

The low thermal mass of these boats facilitates this rapid heating. It reduces the "ramp-up" time for the sample, allowing the experiment to simulate real-world rapid heating conditions effectively.

Ensuring Stability and Data Precision

Moving Between Temperature Zones

A critical phase of these experiments involves moving the fuel from a low-temperature holding zone into the pre-set high-temperature center of the furnace.

This mechanical movement exposes the carrier to extreme thermal shock. The material stability of ceramic and quartz ensures the boat survives this transition without degradation.

Preventing Thermal Deviations

When a sample enters the hot zone, the environment must remain stable to produce valid data.

These boats ensure that no additional thermal deviations are introduced during this transfer. By remaining thermally neutral, they guarantee that the temperature profile experienced by the sample is controlled and predictable.

Capturing Transient Reaction Data

Focusing on Volatile Matter Release

The primary scientific goal in many of these tests is analyzing the release of volatile matter.

This process happens quickly. Because the boats do not delay heat transfer, they allow for the precise capture of transient reaction data during this specific stage.

Reducing Experimental Noise

If a boat with high thermal mass were used, it would dampen the temperature spike.

By using ceramic or quartz, researchers eliminate this "noise," ensuring that the data peaks correspond to the fuel's chemical breakdown, not the carrier's heat absorption.

Common Pitfalls to Avoid

The Risk of High Thermal Mass

It is critical to avoid substituting these specialized boats with heavier or denser materials.

Using a carrier with high thermal mass will introduce a thermal lag. This results in data that suggests a slower reaction rate than what is actually occurring, rendering kinetic analysis inaccurate.

Ignoring Material Stability

While low mass is important, the material must also be stable.

If a boat warps or reacts chemically at high temperatures, it introduces physical deviations. This compromises the geometry of the sample, potentially altering the surface area available for reaction and skewing the transient data.

Making the Right Choice for Your Experiment

To ensure your solid fuel experiments yield publication-grade data, align your equipment choice with your specific analytical goals.

- If your primary focus is Kinetic Accuracy: Prioritize low thermal mass to ensure the sample heating rate matches the furnace environment, capturing true volatile release rates.

- If your primary focus is Process Stability: Rely on the material stability of quartz or ceramic to prevent thermal deviations during the physical movement of the sample into the hot zone.

The choice of sample boat is the difference between measuring the furnace's performance and measuring the fuel's true potential.

Summary Table:

| Feature | Significance in High-Temp Experiments | Benefit for Solid Fuel Analysis |

|---|---|---|

| Low Thermal Mass | Minimizes heat absorption by the carrier | Prevents thermal lag; ensures rapid heating |

| Thermal Stability | Resists deformation during thermal shock | Maintains sample geometry during zone transfer |

| Chemical Inertness | Prevents reactions between boat and sample | Eliminates experimental noise and contamination |

| Rapid Heating | Facilitates instant target temperature reach | Enables precise capture of transient reaction data |

Elevate Your Material Analysis with KINTEK Precision

Maximize the accuracy of your high-temperature experiments with the right equipment. Contact KINTEK today to discover how our high-performance lab solutions can refine your data precision.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized consumables like ceramic and quartz boats. Our lab high-temp furnaces are fully customizable to meet the unique needs of researchers and industrial laboratories. Let us help you eliminate experimental noise—reach out to our specialists now!

Visual Guide

References

- Silin Zeng, Baosheng Jin. Experimental study on No<sub>x</sub> emission and nitrogen conversion characteristics of a coal gangue blended with coal washing mixture. DOI: 10.1088/1742-6596/3013/1/012035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- How does the design of a graphite box optimize the sulfurization of Sb thin films? Key Insights for Film Uniformity

- Why are high-purity alumina crucibles used for LLZO sintering? Master Lithium Volatility Control

- What types of trays are compatible with MoSi2 heating elements? Ensure Optimal Performance and Longevity

- What are the preparation steps for a water circulating vacuum pump? Ensure Optimal Performance and Longevity

- What is the tank capacity of the water circulating vacuum pump? Find the Perfect Fit for Your Lab

- Can alumina ceramic furnace tubes be reused? Maximize Cost Savings and Safety

- Why is the precision of a Mass Flow Controller (MFC) critical for ethanol vapor detection? Master Accurate Gas Mixing