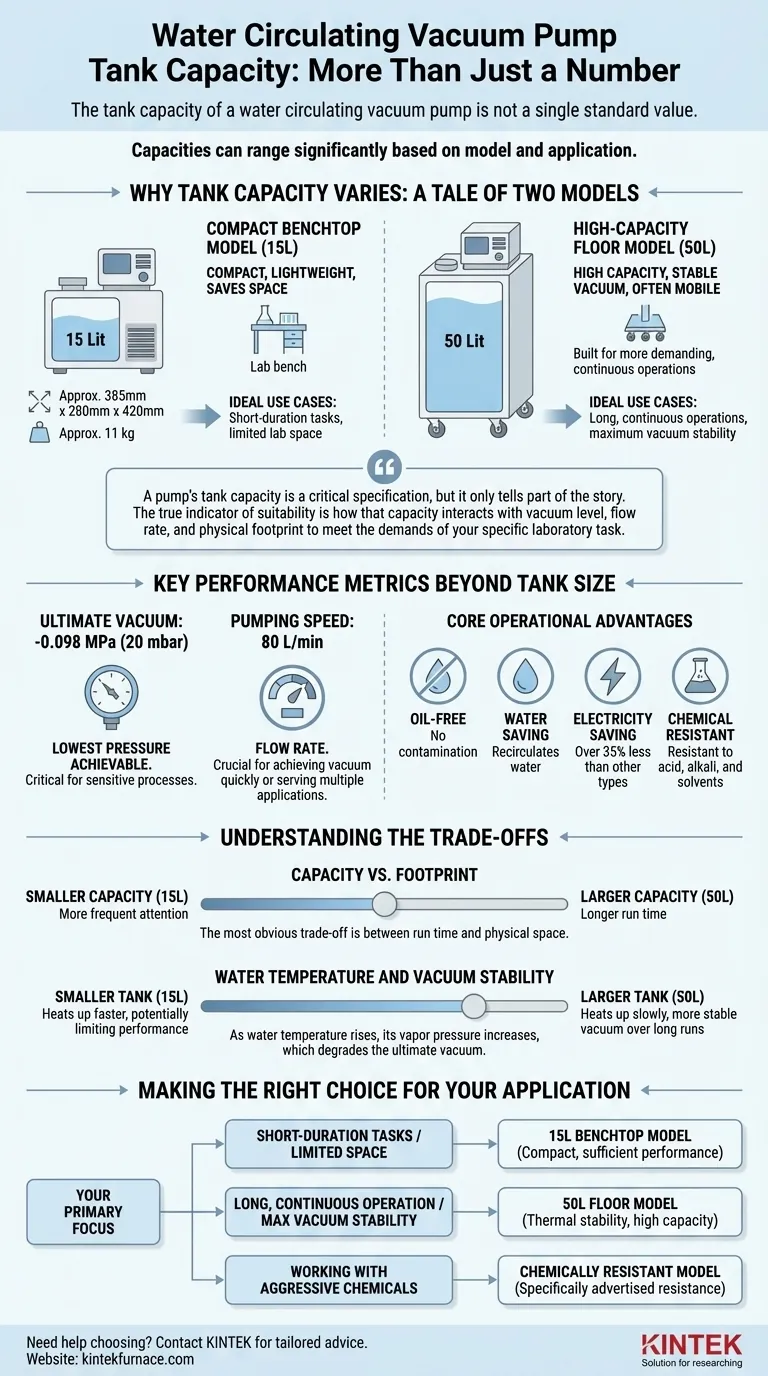

The tank capacity of a water circulating vacuum pump is not a single standard value. Based on typical models, capacities can range significantly, with common examples being 15 liters for smaller, benchtop units and 50 liters for larger, floor-standing models. The correct capacity depends entirely on the specific pump's design and intended application.

A pump's tank capacity is a critical specification, but it only tells part of the story. The true indicator of suitability is how that capacity interacts with vacuum level, flow rate, and physical footprint to meet the demands of your specific laboratory task.

Why Tank Capacity Varies: A Tale of Two Models

The discrepancy in tank capacity reflects two distinct classes of water vacuum pumps, each designed for different use cases and environments.

The Compact Benchtop Model (15L)

A 15-liter tank is characteristic of a compact, benchtop unit. These are designed for applications where space is at a premium.

With dimensions around 385mm x 280mm x 420mm and a weight of approximately 11 kg, this type of pump is ideal for smaller-scale or intermittent work.

The High-Capacity Floor Model (50L)

A 50-liter tank indicates a larger, more robust floor model. These units are built for more demanding, continuous operations.

Their substantial size and weight mean they are often furnished with casters for mobility, prioritizing performance and stability over a minimal footprint.

Key Performance Metrics Beyond Tank Size

To select the right pump, you must look beyond capacity and evaluate the specifications that define its performance.

Ultimate Vacuum (-0.098 MPa)

This is arguably the most important metric. An ultimate vacuum of -0.098 MPa (or 20 mbar) specifies the lowest pressure the pump can achieve. This determines its suitability for sensitive processes like rotary evaporation or filtration that require a strong vacuum.

Pumping Speed (80 L/min)

Pumping speed, or flow rate, indicates how quickly the pump can evacuate air from a system. A flow rate of 80 L/min, often distributed across two or more taps, is crucial for achieving vacuum quickly or serving multiple small applications simultaneously.

Core Operational Advantages

Water circulating pumps are chosen for specific benefits. They use no oil, which prevents contamination of your system and the environment.

They are designed to save water by recirculating it and can save over 35% in electricity compared to other pump types. Models resistant to acid, alkali, and solvents are available for work with corrosive materials.

Understanding the Trade-offs

Choosing a pump involves balancing competing factors. A larger tank is not always better.

Capacity vs. Footprint

The most obvious trade-off is between run time and physical space. A 50L model will operate longer before the water needs changing, but it demands significant floor space. A 15L model fits on a bench but may require more frequent attention.

Water Temperature and Vacuum Stability

This is a critical, often overlooked factor. The pump's operation generates heat, which warms the circulating water. As water temperature rises, its vapor pressure increases, which degrades the ultimate vacuum the pump can achieve.

A larger tank (50L) heats up much more slowly, providing a more stable vacuum level over long, continuous experiments. A smaller tank (15L) will heat up faster, potentially limiting performance during extended runs.

Maintenance and Contamination

The pump's performance depends on the water within it. The closed-loop system prevents waste but means any contaminants introduced will remain. Using clean water and choosing a model with a corrosion-resistant motor and housing is essential for longevity.

Making the Right Choice for Your Application

Your final decision should be guided by your primary laboratory needs.

- If your primary focus is short-duration tasks or limited lab space: A smaller, 15L benchtop model offers sufficient performance with a minimal footprint.

- If your primary focus is long, continuous operation or maximum vacuum stability: A larger, 50L floor model is the superior choice for its thermal stability and capacity.

- If your primary focus is working with aggressive chemicals: Ensure you select a model specifically advertised as being resistant to acids, alkalis, and solvents.

Ultimately, understanding how these core specifications work together empowers you to select the right tool for your specific scientific goal.

Summary Table:

| Model Type | Typical Tank Capacity | Key Features | Ideal Use Cases |

|---|---|---|---|

| Benchtop | 15 liters | Compact, lightweight (approx. 11 kg), saves space | Short-duration tasks, limited lab space |

| Floor-standing | 50 liters | High capacity, stable vacuum, often mobile with casters | Long, continuous operations, maximum vacuum stability |

Struggling to choose the right water circulating vacuum pump for your lab? KINTEK specializes in advanced high-temperature furnace solutions, but our expertise extends to precise lab equipment selection. Leveraging exceptional R&D and in-house manufacturing, we offer diverse products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet unique experimental needs. Let us help you optimize your setup—contact us today for tailored advice and reliable performance!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is firing cotton used as a cushion between the ceramic sample and the tray during sintering? Prevent Distortion

- What is the importance of using a Mass Flow Controller (MFC)? Enhance Molybdenum Phosphide (MoP) Synthesis Precision

- Why are high-purity zirconia grinding balls preferred over steel? Achieve Ultra-Pure Ceramic Grinding Results

- What role does a high-precision mass flow controller play in assessing the gas selectivity of Gallium Sulfide sensors?

- What is lab vacuum used for? Mastering Environmental Control for Purity and Precision

- What factors influence the lifespan of alumina ceramic furnace tubes? Maximize Durability and Performance

- What is the temperature range for Laboratory Type Furnaces? Find Your Ideal Heat Solution

- What functions do alumina crucibles and quartz tube encapsulation serve? Essential Shields for Na2In2As3 Synthesis