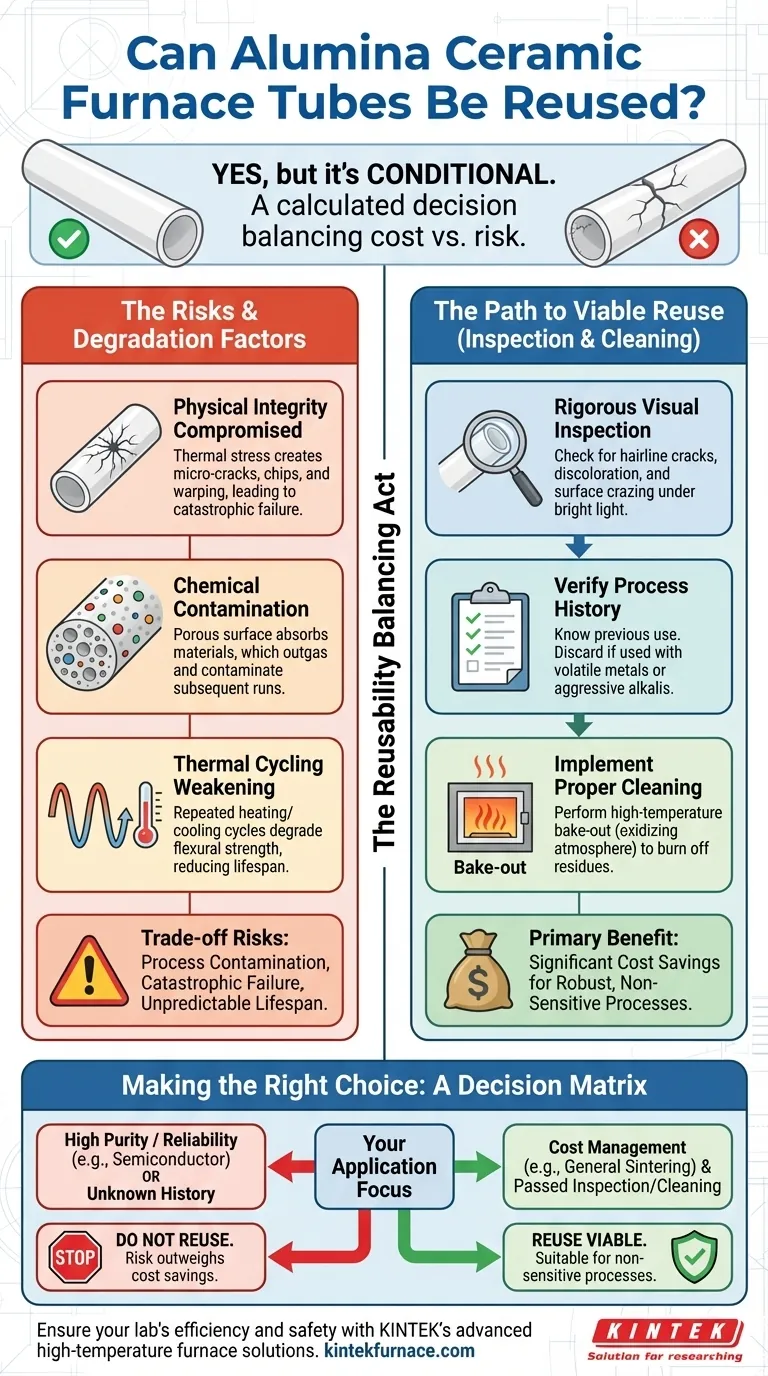

Yes, alumina ceramic furnace tubes can be reused, but this is conditional. A tube is only suitable for reuse if it remains completely free of structural damage and chemical contamination after its initial use. Successful reuse is entirely dependent on a rigorous process of inspection and cleaning to ensure the tube's integrity for subsequent high-temperature applications.

Reusing an alumina tube is a calculated decision that balances cost savings against the significant risks of process contamination and catastrophic failure. The decision to reuse must be based on a thorough inspection, not on assumption.

The Core Principles of Reusability

Understanding why and how alumina tubes degrade is the key to assessing their potential for reuse. The decision goes beyond a simple visual check and requires an appreciation for the stresses a tube endures at high temperatures.

Physical Integrity is Non-Negotiable

Every heating and cooling cycle introduces thermal stress. Over time, these cycles can lead to micro-cracks, which are precursors to failure.

Any visible cracks, chips, or warping are immediate grounds for disqualification. A compromised structure is highly likely to fail at operating temperature, potentially destroying your sample and damaging the furnace itself.

Chemical Contamination is a Silent Threat

Alumina, while highly resistant, is not entirely inert and can be microscopically porous. Materials processed in the tube, especially at high temperatures, can seep into the ceramic's surface.

This absorbed material can then outgas or react in a subsequent run, introducing contaminants that can ruin sensitive processes like semiconductor manufacturing or high-purity material synthesis.

The Impact of Thermal Cycling

Even a tube that appears physically perfect has a finite lifespan. The material's mechanical properties, such as its flexural strength, are slowly degraded by repeated exposure to extreme temperature gradients.

Think of it like repeatedly bending a paperclip; even if it doesn't break, each cycle weakens the material. A tube used many times is inherently weaker than a new one, increasing the risk of failure over time.

Understanding the Trade-offs of Reuse

Opting to reuse a furnace tube is an exercise in risk management. You must weigh the clear financial benefit against potentially severe operational risks.

The Benefit: Cost Savings

The primary motivation for reusing a tube is financial. High-purity alumina tubes can be a significant consumable cost, and extending their life directly reduces operational expenses.

The Risk: Process Contamination

For applications demanding high purity, this is the most critical risk. A tube previously used for one material can release trace elements that contaminate the next batch, rendering expensive research or production runs useless.

The Risk: Catastrophic Failure

A weakened tube that cracks or shatters at high temperature is a major failure event. This can lead to costly furnace repairs, lost work, and significant safety hazards from high temperatures and potential chemical exposures.

The Risk: Unpredictable Lifespan

While a new tube comes with a predictable performance expectation, a used tube does not. Its remaining lifespan is an unknown variable, making it difficult to rely on for long-duration or critical processes.

A Practical Inspection Checklist for Reuse

If you decide the potential benefits outweigh the risks for your application, a formal inspection process is mandatory.

1. Rigorous Visual Inspection

Examine the entire tube, inside and out, under bright light. Look for any hairline cracks, chips, discoloration, or surface crazing. Pay special attention to the ends and any areas that experience the highest thermal gradients.

2. Verify Process History

You must know exactly what the tube was used for. If it was used to process materials containing volatile metals, fluorides, or aggressive alkalis, the risk of chemical retention is extremely high, and the tube should be discarded.

3. Implement Proper Cleaning

If the tube passes visual and historical checks, a cleaning procedure is necessary. This often involves a high-temperature bake-out in an oxidizing atmosphere (like air) to burn off organic residues.

For certain inorganic contaminants, a careful acid wash may be possible, but you must first confirm the chemical compatibility to avoid damaging the tube itself.

Making the Right Choice for Your Application

The decision to reuse an alumina tube is not universal; it depends entirely on the demands of your specific process.

- If your primary focus is ultimate purity or process reliability (e.g., semiconductor, advanced research): Do not reuse the tube. The risk of contamination or failure far outweighs the cost savings.

- If your primary focus is cost management for a robust, non-sensitive process (e.g., general sintering, debinding): Reuse is a viable option, provided the tube passes a strict inspection and cleaning protocol.

- If you have a tube with an unknown history: Do not reuse it under any circumstances. The risk of introducing an unknown and potentially catastrophic contaminant is unacceptable.

Ultimately, your decision should be guided by a clear understanding that a tube's integrity is the foundation of a safe and successful furnace process.

Summary Table:

| Aspect | Key Points |

|---|---|

| Reusability | Yes, if no structural damage or chemical contamination; depends on inspection and cleaning. |

| Risks | Process contamination, catastrophic failure, unpredictable lifespan. |

| Benefits | Cost savings for non-sensitive applications. |

| Inspection | Visual checks for cracks, chips; verify process history; proper cleaning. |

| Suitability | Not for high-purity processes; viable for robust, cost-focused uses. |

Ensure your lab's efficiency and safety with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your processes and reduce risks!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab