In laboratory settings, quartz tubes serve as the default high-performance vessel for processing materials at extreme temperatures. They are most commonly used as the central reaction chamber within a tube furnace, providing a chemically pure and thermally stable environment for processes like annealing, sintering, and chemical vapor deposition.

The core function of a quartz tube is not merely to hold a sample, but to create an isolated, controllable, and non-reactive environment. Its unique combination of thermal shock resistance, high purity, and optical clarity makes it indispensable for advanced materials research and processing.

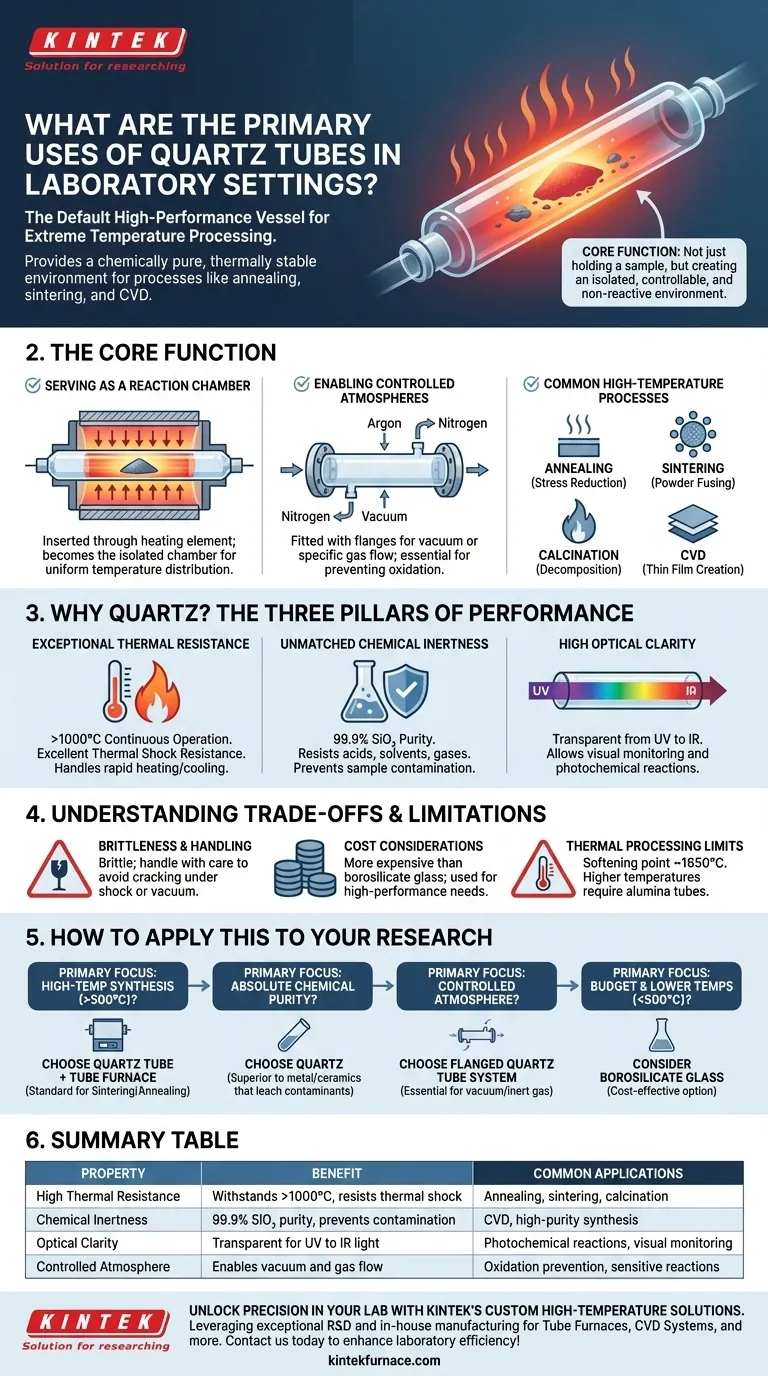

The Core Function: A High-Purity Reaction Environment

The primary role of a quartz tube is to act as the workhorse component inside a laboratory tube furnace, which is designed for precise thermal processing.

Serving as a Reaction Chamber

A quartz tube is inserted through the center of a tube furnace's heating element. Samples or materials are placed inside the tube, which then becomes the isolated chamber where the heat treatment occurs.

This simple structure provides exceptionally uniform temperature distribution along the length of the sample, which is critical for consistent results.

Enabling Controlled Atmospheres

When fitted with sealed flanges on both ends, a quartz tube can be transformed into a completely enclosed system.

This allows researchers to pull a vacuum or flow specific gases (like argon or nitrogen) through the tube during heating. This control over the atmosphere is essential for preventing oxidation and enabling sensitive chemical reactions.

Common High-Temperature Processes

The combination of a tube furnace and a quartz tube is standard for a wide range of thermal processes.

These include annealing (to reduce material stress), sintering (to fuse powders into a solid mass), calcination (to thermally decompose materials), and chemical vapor deposition (CVD) for creating thin films.

Why Quartz? The Three Pillars of Performance

The widespread adoption of quartz is not accidental. It stems from a unique combination of material properties that are ideal for demanding laboratory work.

Exceptional Thermal Resistance

Quartz can withstand continuous operating temperatures well over 1000°C and has excellent thermal shock resistance. This means it can handle rapid heating and cooling cycles without cracking, a common failure point for lesser materials.

Unmatched Chemical Inertness

Fused quartz is exceptionally pure, typically over 99.9% SiO₂. It is chemically inert to a vast range of acids, solvents, and process gases.

This purity ensures that the tube itself does not react with or contaminate the sample being processed, which is paramount for high-purity material synthesis and analysis.

High Optical Clarity

Unlike opaque ceramics, quartz is transparent across a wide spectrum of light, from ultraviolet to infrared. While less critical inside a closed furnace, this property is valuable for applications requiring visual monitoring or photochemical reactions.

Understanding the Trade-offs and Limitations

While powerful, quartz is not a universal solution. Understanding its limitations is key to using it effectively and safely.

Brittleness and Handling

Like any glass, quartz is brittle and susceptible to mechanical shock. It must be handled with care to avoid chipping or cracking, which can lead to catastrophic failure at high temperatures or under vacuum.

Cost Considerations

Quartz is significantly more expensive than standard borosilicate glass (like Pyrex). Its use is typically reserved for applications where its high-temperature performance or chemical purity is a non-negotiable requirement.

Thermal Processing Limits

While excellent, quartz does have a softening point (around 1650°C). For processes requiring even higher temperatures, more advanced and costly ceramic tubes (like alumina) must be considered.

How to Apply This to Your Research

Choosing the right components is fundamental to experimental success. Your decision should be guided by the specific demands of your process.

- If your primary focus is high-temperature material synthesis (>500°C): A quartz tube within a tube furnace is the standard, reliable choice for processes like sintering or annealing.

- If your primary focus is absolute chemical purity: The inert nature of quartz makes it far superior to metallic or most ceramic chambers that can leach contaminants into your sample.

- If your primary focus is working under a specific atmosphere: A flanged quartz tube system is essential for creating the sealed environment needed for vacuum or inert gas flow.

- If your primary focus is budget and lower temperatures (<500°C): A standard borosilicate glass tube may be a more cost-effective option.

By understanding the distinct advantages of quartz, you can leverage it to achieve precise control and reliable outcomes in your thermal processing work.

Summary Table:

| Property | Benefit | Common Applications |

|---|---|---|

| High Thermal Resistance | Withstands >1000°C, resists thermal shock | Annealing, sintering, calcination |

| Chemical Inertness | 99.9% SiO₂ purity, prevents contamination | Chemical vapor deposition (CVD), high-purity synthesis |

| Optical Clarity | Transparent for UV to IR light | Photochemical reactions, visual monitoring |

| Controlled Atmosphere | Enables vacuum and gas flow in sealed systems | Oxidation prevention, sensitive reactions |

Unlock Precision in Your Lab with KINTEK's Custom High-Temperature Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides advanced furnace systems tailored for materials research. Our product line—including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed to meet your unique experimental needs with deep customization capabilities. Whether you're working on annealing, sintering, or CVD processes, our quartz tube-compatible setups ensure superior thermal control and purity.

Contact us today to discuss how we can enhance your laboratory's efficiency and achieve reliable, high-performance results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide