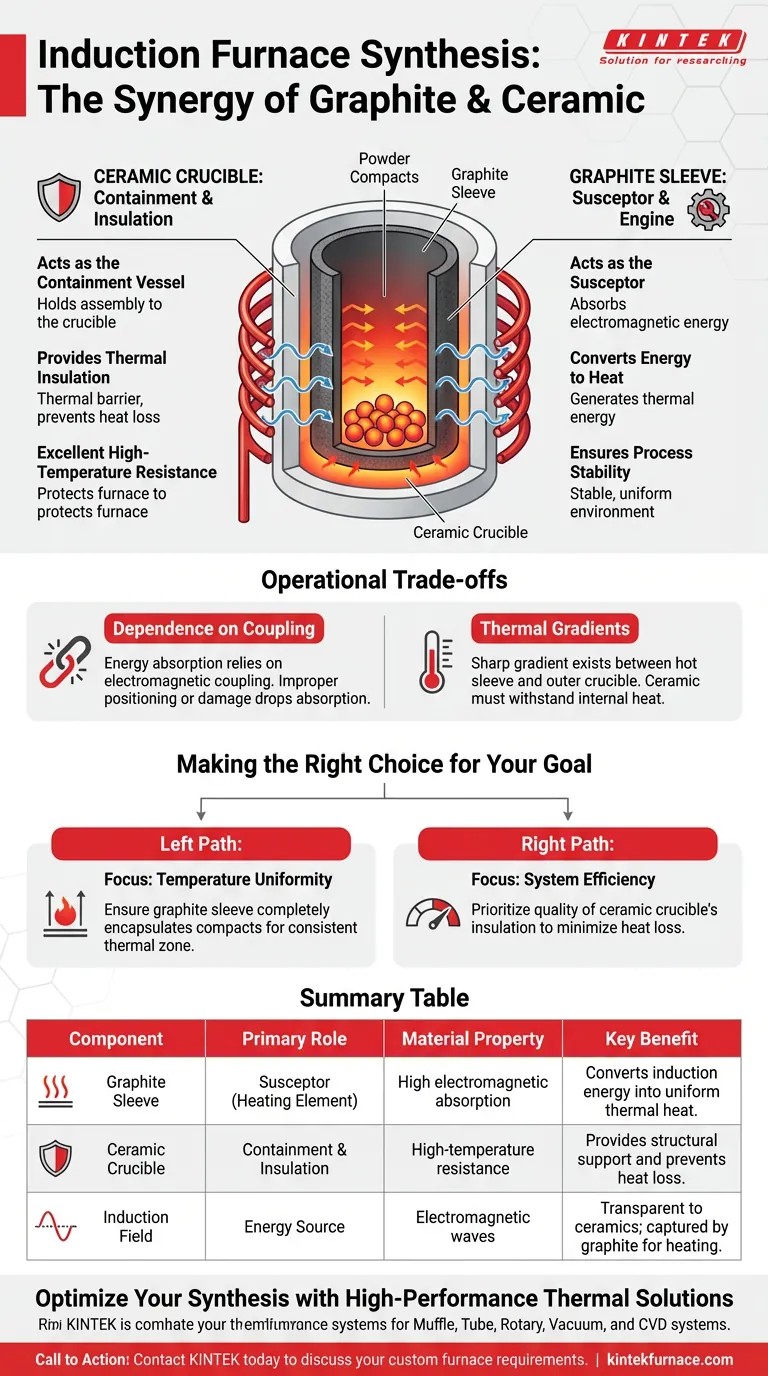

In an induction heating furnace, the ceramic crucible and graphite sleeve serve distinct, complementary functions: containment and energy conversion. The ceramic crucible acts as a thermally insulating vessel that resists high temperatures, while the graphite sleeve, placed inside, acts as the active heating element (susceptor) that converts electromagnetic energy into heat.

The efficiency of this system relies on the synergy between the graphite sleeve, which captures induction currents to generate heat, and the ceramic crucible, which provides the necessary thermal insulation and structural containment.

The Role of the Ceramic Crucible

Acting as the Containment Vessel

The primary function of the ceramic crucible is structural containment. It holds the entire assembly, including the graphite sleeve and the powder compacts intended for synthesis.

Providing Thermal Insulation

Crucially, the ceramic material is characterized by excellent high-temperature resistance.

It serves as a thermal barrier, preventing excessive heat loss to the furnace exterior.

This insulation helps maintain the high temperatures generated inside the vessel while protecting the outer components of the furnace.

The Function of the Graphite Sleeve

Acting as the Susceptor

The graphite sleeve is the "engine" of the heating process. Placed inside the ceramic crucible, it functions as the susceptor.

Because ceramic is generally transparent to induction fields, it does not heat up significantly on its own. The graphite sleeve, however, efficiently absorbs electromagnetic energy generated by the induction currents.

Converting Energy to Heat

Once the graphite absorbs this energy, it directly converts it into thermal energy.

This conversion is what actually raises the temperature within the furnace, rather than the induction coil heating the material directly (unless the material itself is conductive).

Ensuring Process Stability

The graphite sleeve does more than just generate heat; it regulates the environment.

It provides a stable and uniform high-temperature environment for the powder compacts. This uniformity is critical for consistent material synthesis.

Understanding the Operational Trade-offs

Dependence on Coupling

The system relies entirely on the electromagnetic coupling of the graphite.

If the sleeve is damaged or improperly positioned, energy absorption drops, and the furnace cannot reach the required synthesis temperatures, regardless of the power input.

Thermal Gradients

While the graphite sleeve ensures uniformity inside the reaction zone, a sharp thermal gradient exists between the sleeve and the outer ceramic crucible.

The ceramic must be robust enough to withstand this internal heat without cracking, highlighting the importance of the crucible's high-temperature resistance properties mentioned in your reference.

Making the Right Choice for Your Goal

When designing or operating an induction setup for material synthesis, consider how these components align with your objectives:

- If your primary focus is Temperature Uniformity: Ensure the graphite sleeve encapsulates the powder compacts completely to create a consistent thermal zone.

- If your primary focus is System Efficiency: Prioritize the quality of the ceramic crucible's insulation to minimize heat loss from the active graphite element.

Ultimately, successful synthesis depends on the graphite sleeve efficiently generating heat while the ceramic crucible effectively traps it.

Summary Table:

| Component | Primary Role | Material Property | Key Benefit |

|---|---|---|---|

| Graphite Sleeve | Susceptor (Heating Element) | High electromagnetic absorption | Converts induction energy into uniform thermal heat. |

| Ceramic Crucible | Containment & Insulation | High-temperature resistance | Provides structural support and prevents heat loss. |

| Induction Field | Energy Source | Electromagnetic waves | Transparent to ceramics; captured by graphite for heating. |

Optimize Your Synthesis with High-Performance Thermal Solutions

Precise material synthesis requires the perfect balance of heat generation and containment. At KINTEK, we understand the critical synergy between susceptors and insulation. Backed by expert R&D and manufacturing, we offer a comprehensive range of lab high-temp equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to your unique research needs.

Ready to enhance your lab’s thermal efficiency? Contact KINTEK today to discuss your custom furnace requirements and leverage our expertise in advanced material processing.

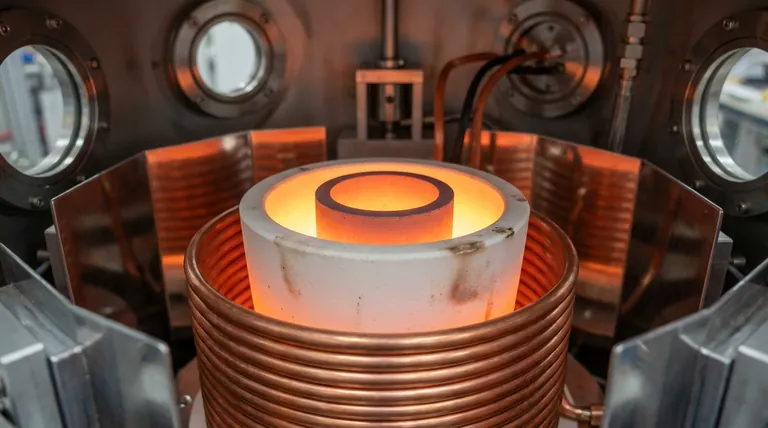

Visual Guide

References

- Gülizar Sarıyer, H. Erdem Çamurlu. Production and Characterization of Ni0.50 Al0.50 and Ni0.55 Al0.45 Powders by Volume Combustion Synthesis. DOI: 10.17776/csj.1280582

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the primary function of a quartz tube in SnSe preparation? Ensure High-Purity Alloy Synthesis

- What is the purpose of using quartz vacuum encapsulation? Optimize La(Fe,Si)13-based Magnetocaloric Alloys

- Why are high-purity alumina crucibles necessary for Li2Mg3Ti(1-x)ZrxO6 sintering? Ensure Dielectric Excellence

- What manufacturing processes rely on laboratory furnaces? Precision Heat Treatment for Advanced Materials

- What is the function of a specifically designed annealing vessel in SVA? Enhance Your Film Crystallization Today

- Why must high-pressure microwave reaction vessels maintain excellent sealing performance? Ensure Carbon Synthesis Success

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- What role does a quartz substrate holder play in MoS2 growth? Optimize Thin Film Deposition with Precision Hardware