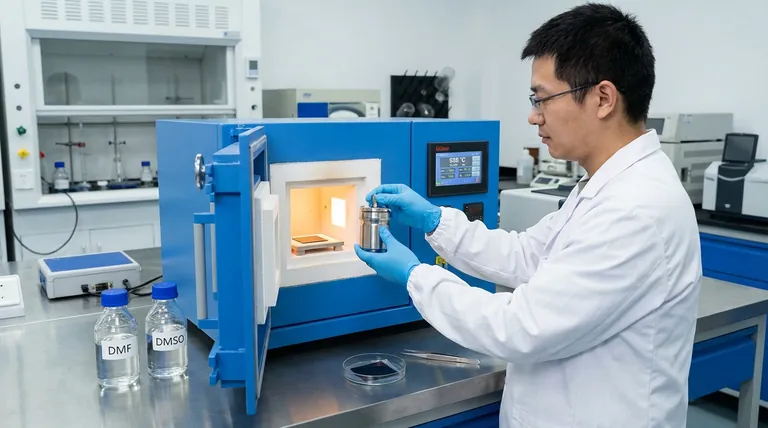

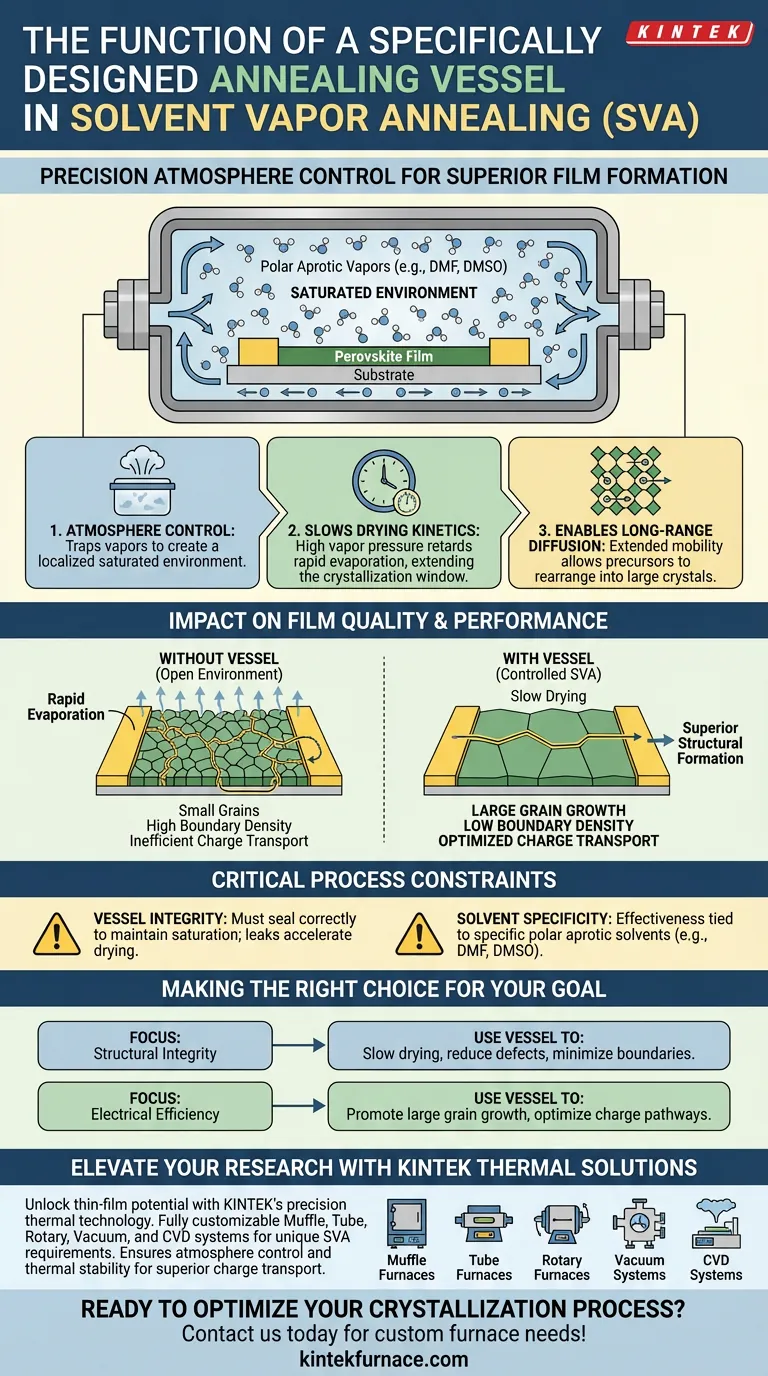

A specifically designed annealing vessel serves as a containment chamber for precision atmosphere control. Its primary function is to trap polar aprotic solvent vapors—such as DMF or DMSO—to create a localized, saturated environment around the film. This saturation directly counteracts rapid evaporation, effectively slowing the drying rate of the perovskite film to allow for superior structural formation.

The vessel's primary utility is to extend the crystallization window by maintaining a high-vapor-pressure environment. This facilitates long-range precursor diffusion, leading to larger crystal grains and optimized electrical pathways.

The Mechanism of Atmosphere Control

Creating a Saturated Environment

The vessel is engineered to hold a specific volume of solvent vapor. By confining the atmosphere, it ensures the air surrounding the sample remains saturated with polar aprotic solvents.

Slowing Drying Kinetics

In an open environment, solvents evaporate quickly, freezing the film structure in place prematurely. The annealing vessel prevents this by keeping the vapor pressure high. This significantly slows the drying rate, keeping the film in a semi-liquid or solvated state for a longer duration.

Enabling Long-Range Diffusion

Because the drying process is retarded, the precursor ions and molecules within the film retain mobility for a longer period. This extended mobility allows for long-range diffusion, enabling components to move and rearrange into more thermodynamically favorable positions.

Impact on Film Quality and Performance

Promoting Large Grain Growth

The extended diffusion time allows perovskite grains to expand significantly. The vessel's environment enables these grains to grow large enough to span across the electrodes, rather than forming a patchwork of small, disconnected crystals.

Reducing Grain Boundary Density

As grains grow larger, the number of interfaces (boundaries) between them naturally decreases. A lower grain boundary density is critical because these boundaries often act as defects that trap charges.

Optimizing Charge Transport

The ultimate function of the vessel is to enhance the film's electrical properties. By creating larger grains and fewer boundaries, the process establishes optimized charge transport pathways, allowing electrons to move through the material with less resistance.

Critical Process Constraints

Dependence on Vessel Integrity

The entire process relies on the vessel's ability to maintain saturation. If the vessel is not "specifically designed" to seal correctly, vapors will escape, the drying rate will accelerate, and the long-range diffusion necessary for large grain growth will not occur.

Specificity of Solvents

The reference highlights the use of polar aprotic solvents like DMF and DMSO. The vessel's effectiveness is tied to the chemical properties of these specific solvents; using solvents with different vapor pressures or polarity without adjusting the vessel design may yield poor results.

Making the Right Choice for Your Goal

When designing your fabrication process, consider how the annealing vessel aligns with your performance metrics:

- If your primary focus is Structural Integrity: Use the vessel to slow drying times, which allows for the reduction of grain boundary density and physical defects.

- If your primary focus is Electrical Efficiency: Rely on the vessel to promote the growth of large grains that span electrodes, ensuring optimized charge transport pathways.

The specifically designed vessel is not just a container; it is an active tool for manipulating the kinetics of crystallization to achieve high-performance perovskite films.

Summary Table:

| Feature | Function in SVA Process | Impact on Material Quality |

|---|---|---|

| Atmosphere Control | Traps polar aprotic vapors (DMF/DMSO) | Creates saturated localized environment |

| Drying Kinetics | Retards solvent evaporation rate | Extends the crystallization window |

| Precursor Mobility | Enables long-range ionic diffusion | Promotes large grain growth across electrodes |

| Grain Boundaries | Reduces interface density | Minimizes charge-trapping defects |

Elevate Your Research with Precision Thermal Solutions

Unlock the full potential of your thin-film fabrication with KINTEK’s industry-leading thermal technology. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique SVA and annealing requirements.

Whether you are scaling up perovskite solar cell production or optimizing semiconductor grain growth, our precision-engineered equipment ensures the atmosphere control and thermal stability necessary for superior charge transport.

Ready to optimize your crystallization process? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Shengcong Wu, Peng Gao. Temperature Matters: Enhancing Performance and Stability of Perovskite Solar Cells through Advanced Annealing Methods. DOI: 10.3390/chemistry6010010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a heat-resistant steel retort play in sintering? Mastering Isolation and Pressure for High-Purity Results

- What is the primary function of the transparent quartz tube in the Floating-Zone technique? Optical & Atmospheric Control

- Why is a laboratory vacuum degasser necessary for biochar? Ensure Accurate BET Structural Characterization

- What factors should be considered when selecting an alumina ceramic furnace tube? Ensure Safety and Performance in High-Temp Processes

- What are the specific functions of high-purity graphite molds in SPS? Optimize Your Sintering Process

- What are the technical advantages of using a quartz tube as a reaction chamber? Optimize g-C3N4 Thin Film CVD Processes

- Why are high-precision mass flow controllers necessary for h-BN CVD growth? Ensure Superior Film Stoichiometry

- Which industries can benefit from using the circulating water multifunctional vacuum pump? Discover Clean, Efficient Vacuum Solutions